Method for treating fermentation waste liquid of marigold flowers

A technology of fermentation waste liquid and treatment method, which is applied to fertilizers, applications, and organic fertilizers made of biological waste, and can solve problems such as crop death, large sewage treatment costs, and complex components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

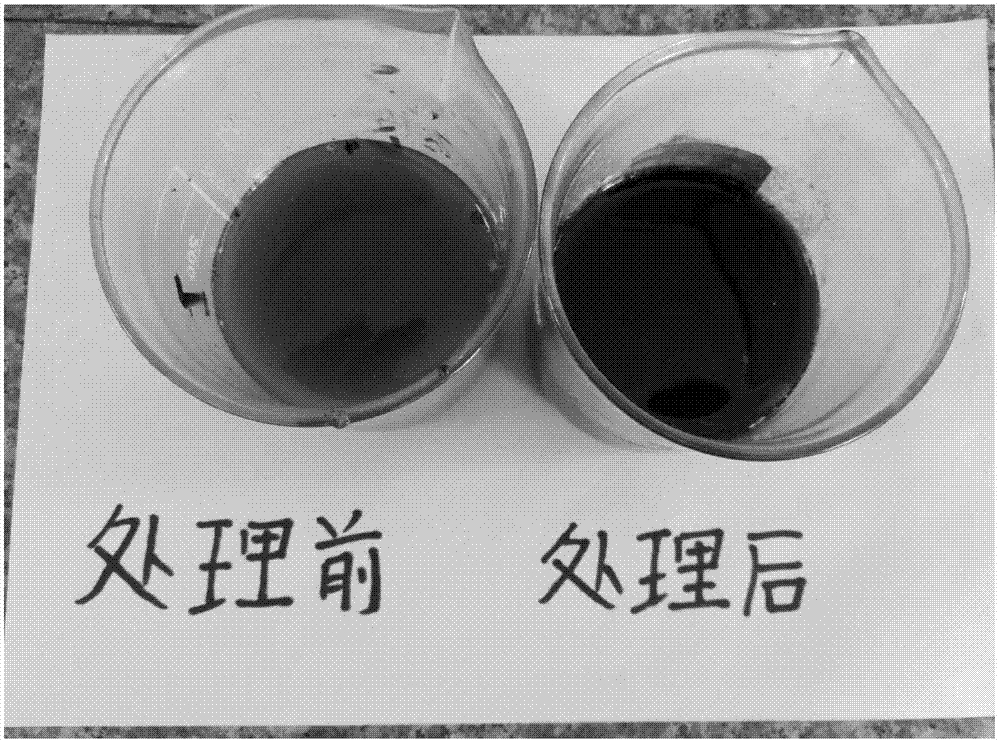

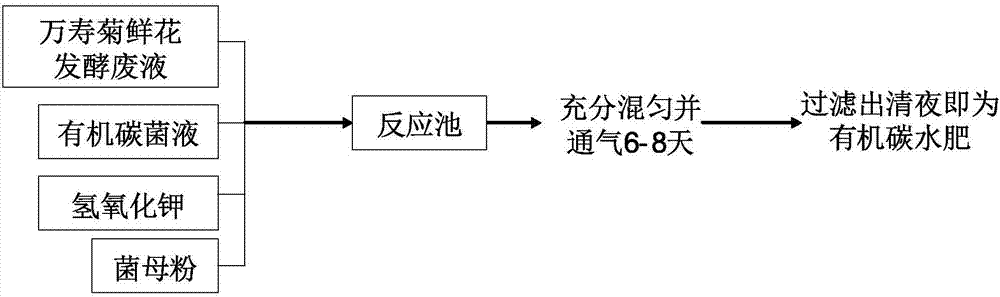

[0022] like figure 2 As shown, the treatment method of marigold flower fermentation waste liquid:

[0023] (1) take by weighing each component on the basis of the weight of the marigold flower fermentation waste liquid to be treated: 100t marigold flower fermentation waste liquid (water content 95.0%, water-soluble organic matter content is 3.0%, pH=4.0), take by weighing 0.2t organic carbon bacteria liquid, 0.5t potassium hydroxide and 0.002t Bacillus coagulans inoculum;

[0024] (2) above-mentioned marigold flower fermentation waste liquid, organic carbon bacteria liquid, potassium hydroxide and bacillus coagulans inoculum are mixed to obtain mixed solution;

[0025] (3) under the condition of room temperature, in the above-mentioned mixed solution, uniformly and continuously pass into the air with the ventilation rate of 0.030L / L*min and stop the ventilation after 8d treatment to obtain the treated liquid;

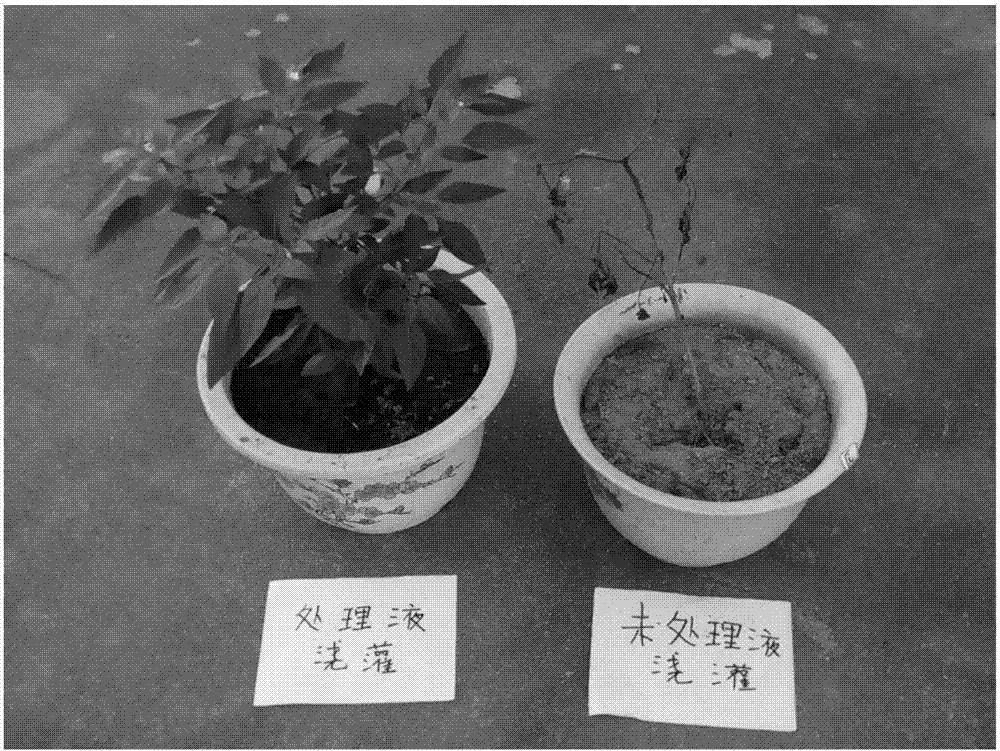

[0026] (4) liquid is carried out solid-liquid separation with a...

Embodiment 2

[0029] like figure 2 As shown, the treatment method of marigold flower fermentation waste liquid:

[0030] (1) take by weighing each component on the basis of the weight of the marigold flower fermentation waste liquid to be treated: 100t marigold flower fermentation waste liquid (water content 97.0%, water-soluble organic matter content is 1.5%, pH=5.0), take by weighing 0.15t organic carbon bacteria liquid, 0.4t potassium hydroxide and 0.002t Bacillus coagulans inoculum;

[0031] (2) above-mentioned marigold flower fermentation waste liquid, organic carbon bacteria liquid, potassium hydroxide and bacillus coagulans inoculum are mixed to obtain mixed solution;

[0032] (3) under room temperature conditions, in the above-mentioned mixed solution, uniformly and continuously pass into the air with the ventilation rate of 0.025L / L*min and stop the ventilation after 7d treatment to obtain the treated liquid;

[0033] (4) liquid is carried out solid-liquid separation with above-...

Embodiment 3

[0036] like figure 2 As shown, the treatment method of marigold flower fermentation waste liquid:

[0037] (1) take by weighing each component on the basis of the weight of the marigold flower fermentation waste liquid to be treated: 100t marigold flower fermentation waste liquid (water content 99.0%, water-soluble organic matter content is 1.0%, pH=6.0), take by weighing 0.1t organic carbon bacteria liquid, 0.3t potassium hydroxide and 0.002t Bacillus coagulans inoculum;

[0038] (2) above-mentioned marigold flower fermentation waste liquid, organic carbon bacteria liquid, potassium hydroxide and bacillus coagulans inoculum are mixed to obtain mixed solution;

[0039] (3) under the condition of room temperature, in the above-mentioned mixed solution, uniformly and continuously pass into the air with the ventilation rate of 0.020L / L*min and stop the ventilation after 6d treatment to obtain the treated liquid;

[0040] (4) liquid is carried out solid-liquid separation with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com