Side body clamp flexible conveying and switching system

A switching system and fixture technology, applied in manufacturing tools, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of large difference in outer surface, non-reusability, large investment, etc., and achieve low production cost, convenient installation, and easy switching. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

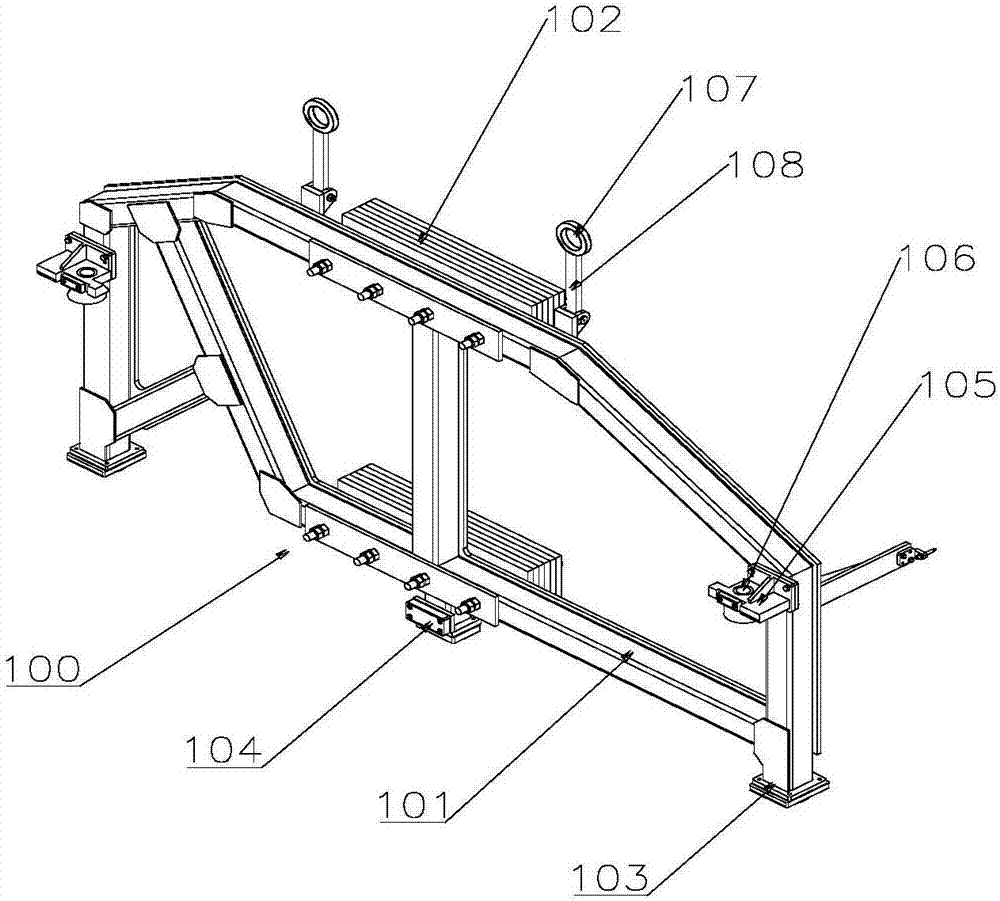

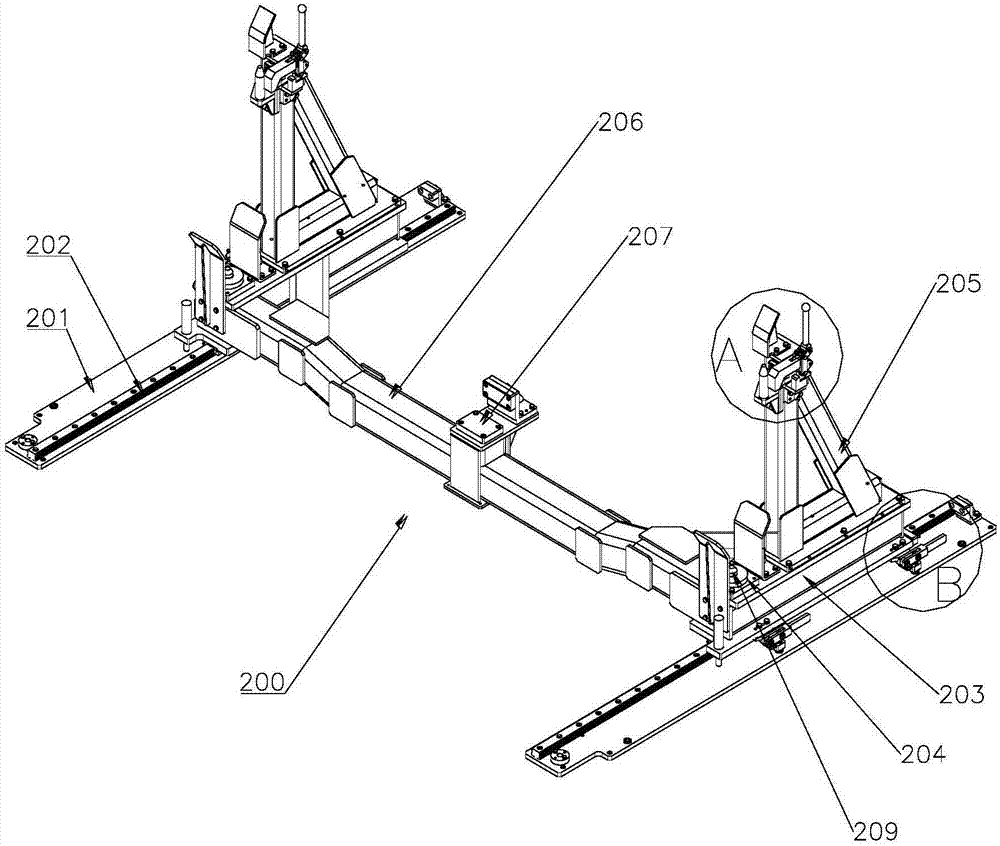

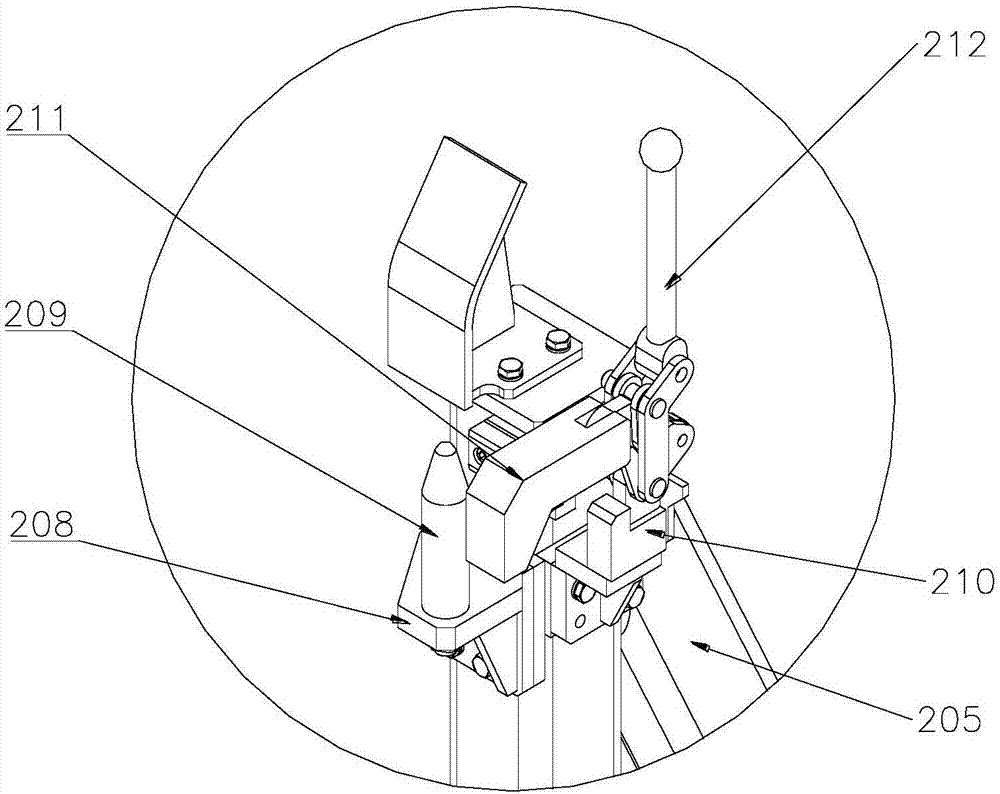

[0021] Such as Figure 1-2 As shown, a side wall clamp flexible transmission switching system is used for the transportation and assembly of the car side wall in the trial production line based on the two-story steel structure platform. The flexible transmission and switching system of side enclosure clamps includes a clamp flexible switching mechanism 100 arranged on the second floor of the two-story steel structure platform, and a workpiece pushing mechanism 200 arranged on both sides of the main station on the first floor of the two-story steel structure platform. The side wall is fixed to the clamp flexible switching mechanism 100 through the side wall clamp, and then the transmission device transports the clamp flexible switching mechanism 100 to the workpiece pushing mechanism 200, and the workpiece pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com