A kind of preparation method of all-metal active material with powder packing structure

An active material and all-metal technology, which is applied in the field of all-metal active material preparation, can solve the problems of temperature sensitivity and lowering, and achieve the effect of realizing secondary deformation, simplifying the process and improving the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

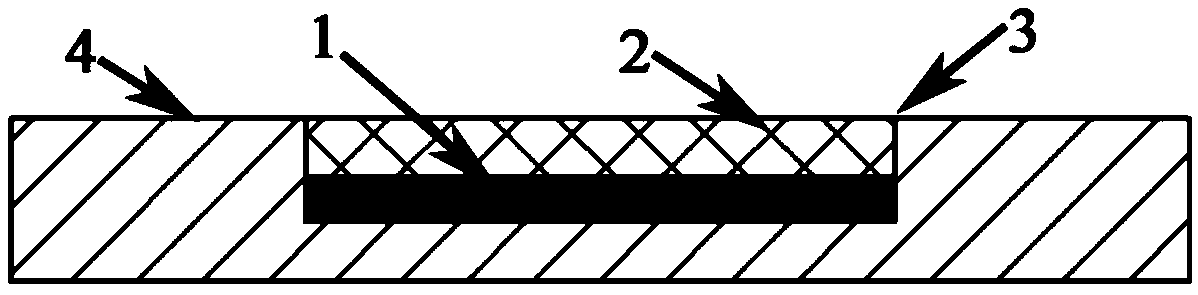

[0021] This embodiment relates to a method for preparing an all-metal active material with an Al-Ni binary system powder stacked structure, comprising the following steps: preparing an Al-Ni active material blank 1 by cold spraying; wherein the Al-Ni active material blank The size of body 1 is: 40mm×30mm×3mm (length×width×thickness); the molar ratio of Al and Ni components is 1:1; the particle size of the powder is 10-30μm.

[0022] Take the aluminum alloy cover plate 2 and the aluminum alloy base plate 4 provided with the groove 3; the size of the aluminum alloy cover plate 2 is: 40mm×30mm×4mm (length×width×thick); the size of the aluminum alloy base plate 4 is: 80mm×60mm×11mm (length×width×thick); the size of the groove 3 is: 40mm×30mm×7mm (length×width×depth); the cover plate 2 and the bottom plate 4 are both 6061 series aluminum alloy.

[0023] Place the Al-Ni active material green body 1 in the groove 3, then put the cover plate 2, and cooperate with the bottom plate 4 to...

Embodiment 2

[0026] The implementation method of this embodiment is the same as that of Example 1, except that the powder stacked structure all-metal active material green body is an Al-Ni-W ternary metal powder active material prepared by cold spray molding; The composition and mole fraction of the Al-Ni-W active material are: Al:Ni:W=2:2:1; the sheath material is 6063 series aluminum alloy.

[0027] The multi-pass continuous cold rolling process is adopted, the rolling speed is 200mm / s, and the deformation in each pass is 10%. A total of 6 passes of continuous rolling are carried out, and the thickness of the final rolled plate is 1.6mm. No heat treatment is done before and after each pass of rolling.

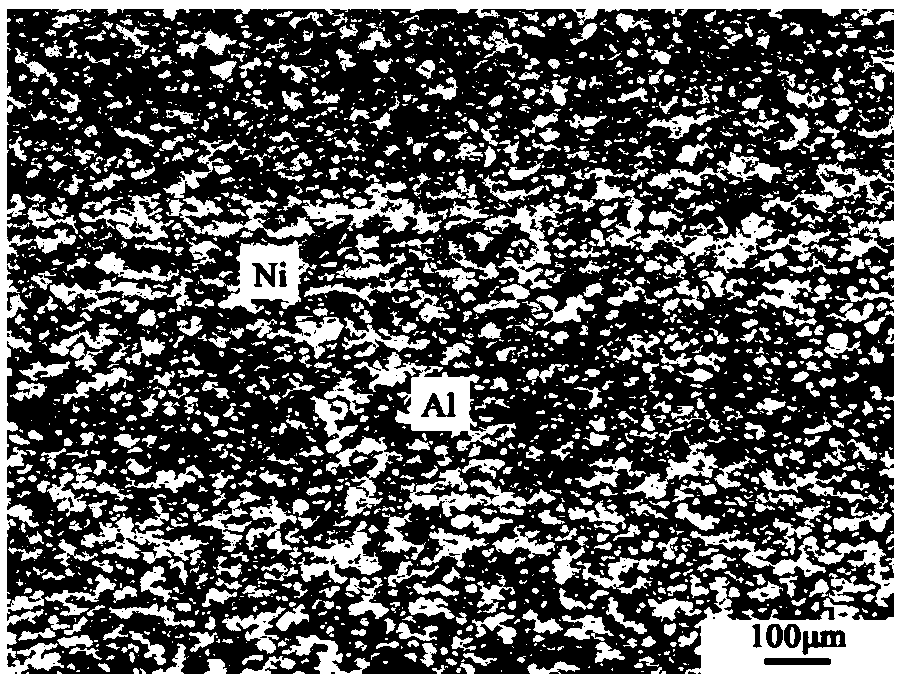

[0028]Implementation effect: after adding sheathing and rolling, the surface of the Al-Ni-W active material has no cracks and is of good quality, while the green body without sheathing is broken during the rolling process. The results of microstructure analysis show that the distribution...

Embodiment 3

[0030] The implementation method of this embodiment is the same as that of Example 1, the difference is that the powder stacked structure all-metal active material green body is an Al-Cu binary metal powder active material prepared by a powder explosion molding method; the Al- The composition and mole fraction of the Cu active material are: Al:Cu=1:1; the sheath material is pure copper.

[0031] The multi-pass continuous cold rolling process is adopted, the roll diameter is 250mm, the rolling speed is 400mm / s, and the deformation per pass is 30%;

[0032] Implementation effect: similar to the result of Example 1, after the sheath rolling is adopted, there is no crack on the surface of the Al-Cu active material. The results of microstructure analysis show that Al and Cu particles have undergone severe plastic deformation, and the contact area between Al and Cu components per unit volume has increased by 50%, and there is no intermediate compound reaction between components duri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com