Desulfurization tower defogging device and desulfurization and dust removal device

A demisting device, desulfurization and dust removal technology, applied in the field of desulfurization tower demisting device and desulfurization and dust removal device, can solve the problems of tower resistance increase, waste of manpower and material resources, demisting efficiency, desulfurization efficiency decline, etc., and achieve good results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

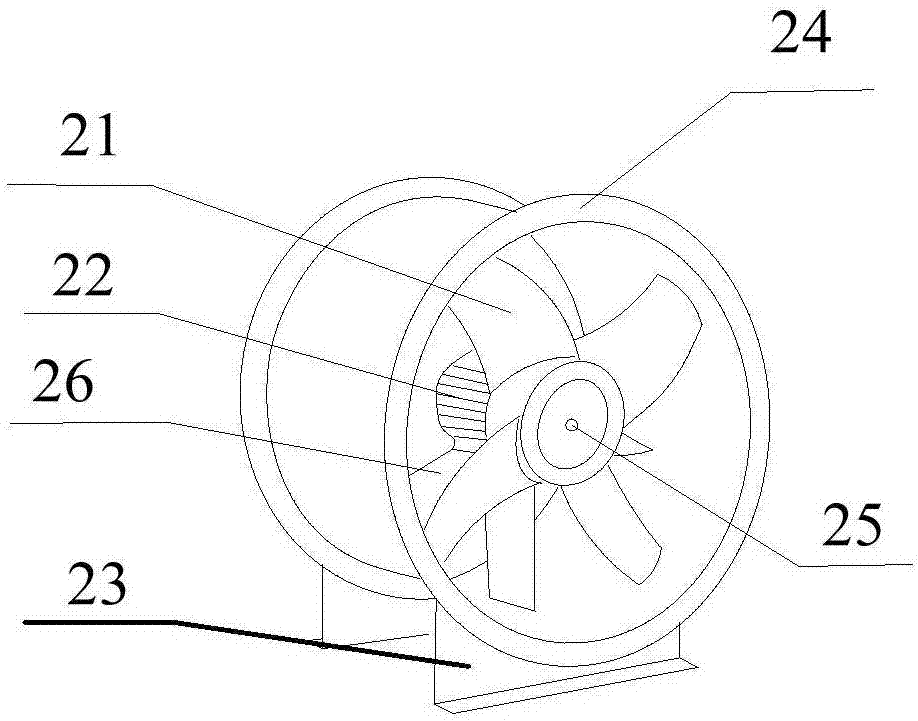

[0033] figure 1 The structural schematic diagram of the desulfurization tower demisting device 1 provided for the embodiment of the present invention, as figure 1As shown, the desulfurization tower defogging device 1 provided by the embodiment of the present invention is used to defog the gas discharged from the desulfurization tower. And the exhaust fan 2, the defogging part 102 is an annular structure formed by a plurality of blades 103, and its inner ring diameter is 1 / 6-1 / 4 of the diameter of the ventilation pipe 101, and the outer ring of the defogging part 102 and the ventilation pipe 101 The inner surface of the air duct 101 is connected, and a plurality of blades 103 are divergently distributed in the shape of a clockwork wheel, and they are all inclined in the same direction. The angle between the blade surface of the blade 103 and the cross section of the ventilation pipe 101 is in the range of 60°-80°. There are multiple defogging components 102, which are respecti...

Embodiment 2

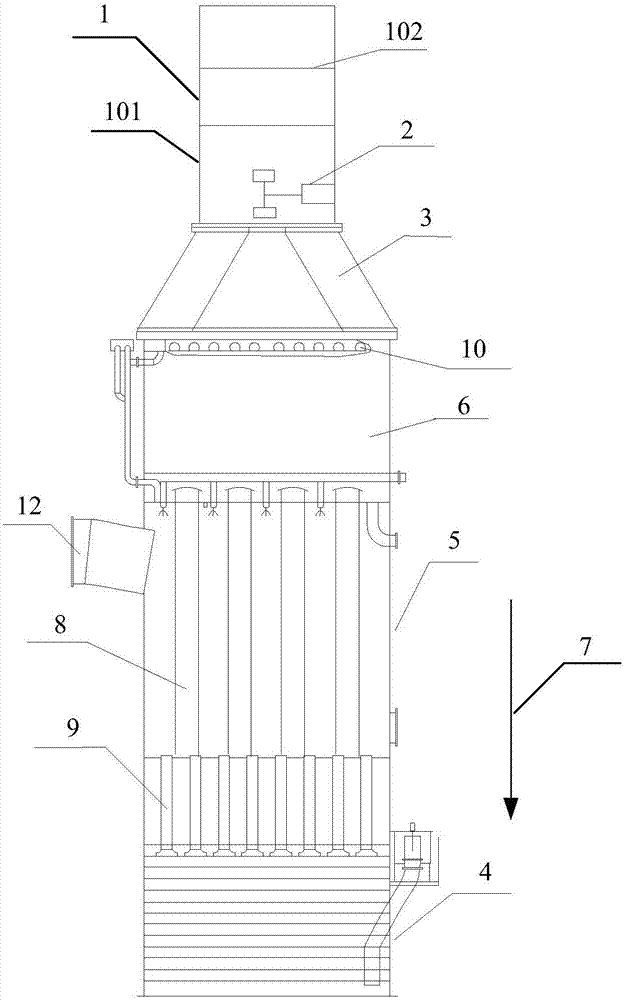

[0042] image 3 The desulfurization and dust removal device provided for the embodiment of the present invention, such as image 3 As shown, the desulfurization and dust removal device provided by the embodiment of the present invention includes a multi-stage filter tower and the desulfurization tower demist device 1 of the above technical solution, and the desulfurization tower demist device 1 is connected to the top of the multi-stage filter tower.

[0043] Furthermore, the desulfurization and dust removal device can be a complete shell, which is divided into different functional sections through different structural bodies. Alternatively, it can also be formed by connecting independent functional sections with different processing capabilities through welding, riveting and other means.

[0044] The desulfurization and dust removal device provided by the embodiment of the present invention includes a multi-stage filter tower and the demist removal device 1 of the above-ment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com