Automobile storage battery tray

A battery and battery bracket technology, which is applied to battery pack components, battery isolation from its environment, and circuits, can solve the problems of incompatibility with two types of batteries, unfavorable vehicle lightweight, and inconvenient use, so as to achieve good fixation and improve Performance and service life, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

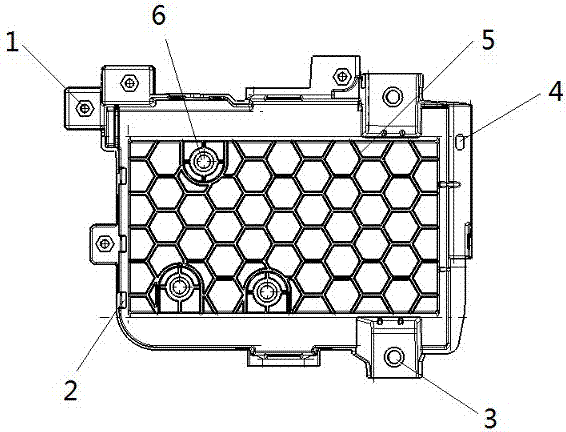

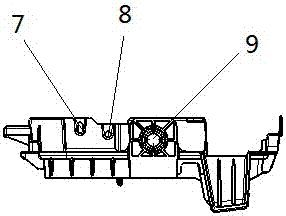

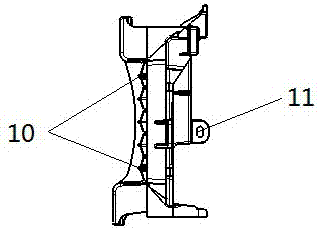

[0020] Such as figure 1 As shown, the tray body is made of PP+LGF40 material injection molding. A groove for fixing the first storage battery is provided in the tray body, and reinforcing ribs 5 are provided on the bottom of the groove, and the reinforcing ribs 5 are in the shape of a regular hexagonal array. A storage battery limiting boss 2 is provided in the tray body along the periphery of the upper bottom surface, and the battery limiting boss 2 is used to fix the second storage battery, and the said upper bottom surface is flush with the groove port plane. There are three battery bracket installation holes 6 on the bottom of the groove, and the battery bracket installation holes are used for fixing the tray body and the battery bracket; the two legs of the tray body are provided with longitudinal beam installation holes 3, and the longitudinal beam installation holes 3 are used for the tray The main body is fixed to the side member of the vehicle body. A component inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com