Truck scale limit automatic adjustment device and method

An automatic adjustment and truck scale technology, which is applied to measuring devices, instruments, weighing, etc., can solve problems such as changes in limit gaps, and achieve the effects of reducing failure rates, automatic adjustment, and improving adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

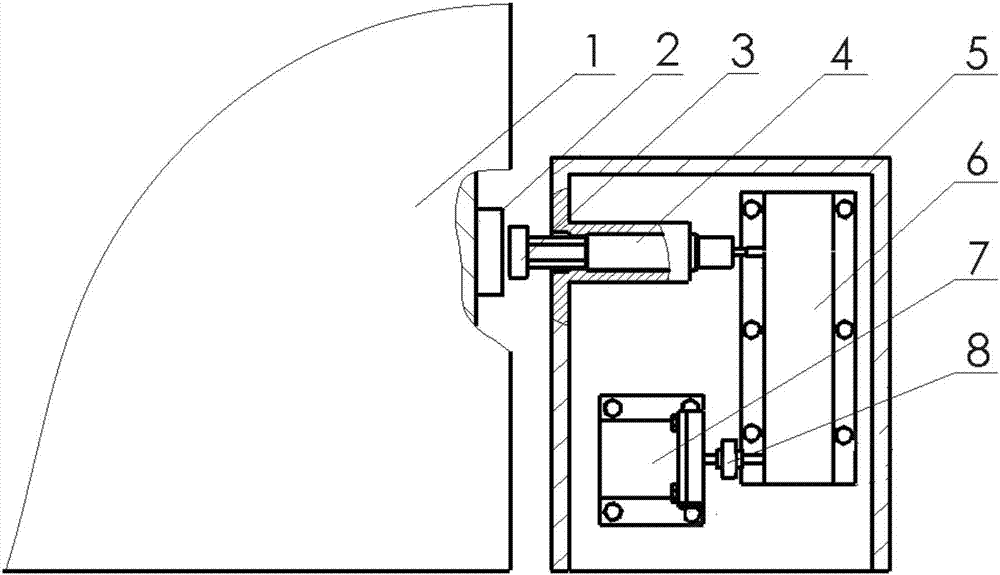

[0019] Depend on figure 1 , figure 2 It can be seen that the auto scale limit automatic adjustment device of the present invention includes a limit bumper 2, a limit screw 4, a box body 5, a reducer 6, a servo motor 7, a handle 8, a normally open proximity switch 9, and a normally closed proximity switch 11 And J1 relay and J2 relay.

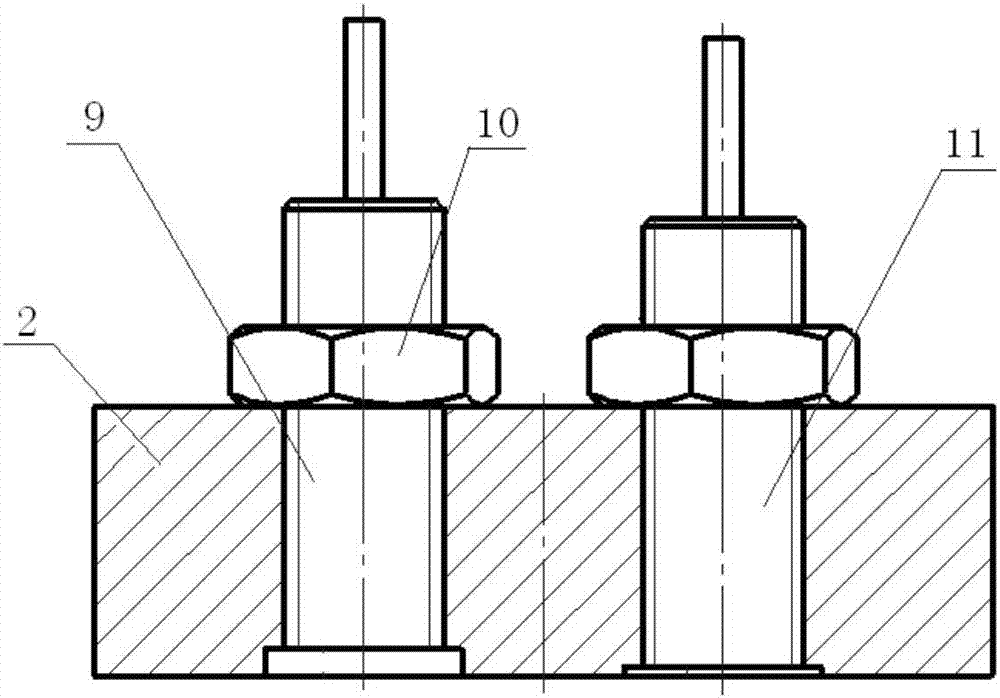

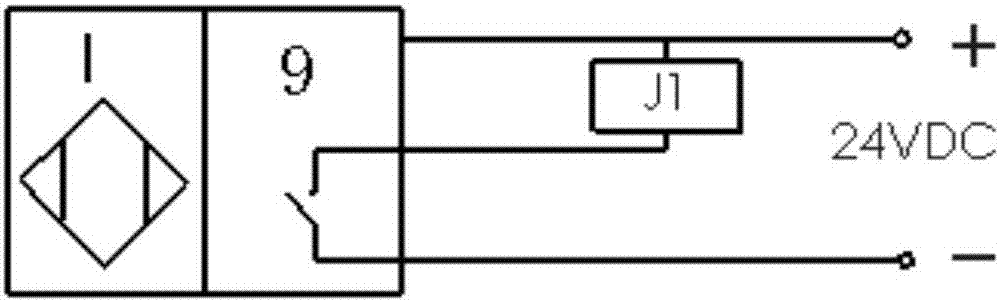

[0020] A through hole with an internal thread is respectively processed on both sides of the limit bumper 2, one of the through holes has a 1.0mm deep shallow pit at the rear end, and the other through hole has a 3.0mm deep deep pit at the rear end. In the through hole of the pit, a normally open proximity switch 9 is threaded, and the normally open proximity switch 9 is connected to the J1 relay (see image 3 ); the normally closed proximity switch 11 is connected by thread in the through hole of the shallow pit, and the normally closed proximity switch 11 is connected to the J2 relay (see Figure 4 ); the normally open proximity switch 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com