A method for testing the accuracy of a borehole imager

A technology of drilling imaging and inspection methods, which is applied in construction and other fields, can solve the problems of inability to inspect positioning accuracy, lack of quantification methods, lack of data support for test results, etc., and achieve the effect of convenient and accurate test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention is described in further detail below in combination with the accompanying drawings and specific embodiments.

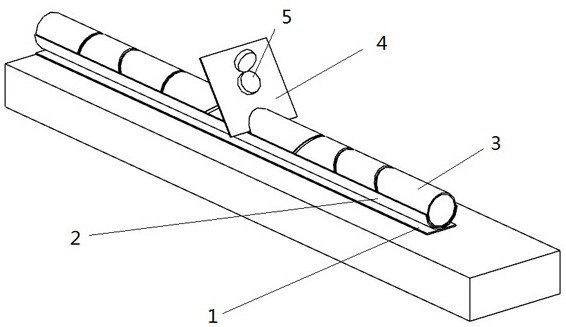

[0021] The invention simulates a section of borehole containing several fractures, first uses the compass to measure the actual occurrence of these fractures, then uses the borehole imager to test the simulated borehole, analyzes the occurrence of these fractures through the supporting software of the imager, and compares the analyzed occurrence with the actual occurrence, so as to determine the accuracy of the occurrence analyzed by the borehole imager.

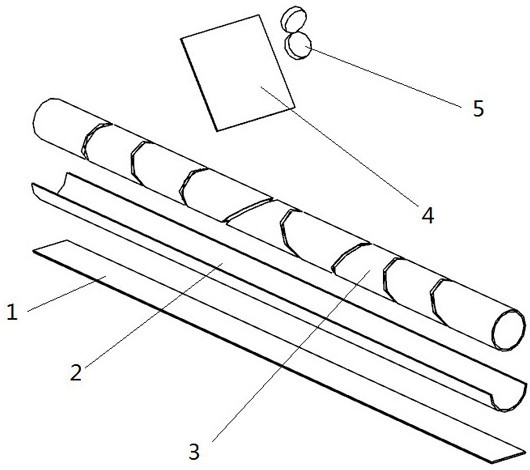

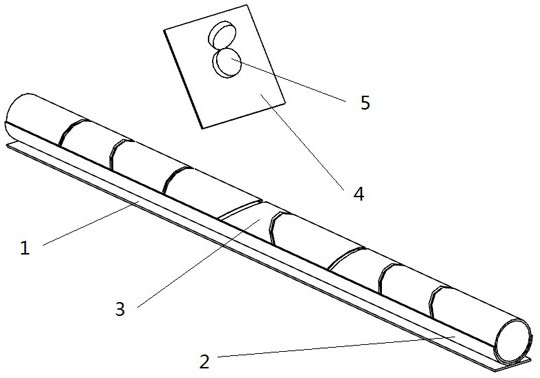

[0022] See attachment Figure 1 and Figure 2 The drilling simulation device comprises a wooden base 1 (of course, other materials can also be used to meet the use requirements) and a bracket 2 arranged on the wooden base 1 for placing the simulated drilling hole wall 3.

[0023] Among them, the specifications of wooden base 1 are: length, width and thickness are 3.0m, 0.1M and 0.02M respectively. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com