Spiral extrusion type solid-liquid separator

A solid-liquid separator, screw extrusion technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of reducing the pressure of the body, poor sealing performance, large air circulation, etc., to improve the internal pressure of the body, improve the sealing performance, reduce The effect of moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

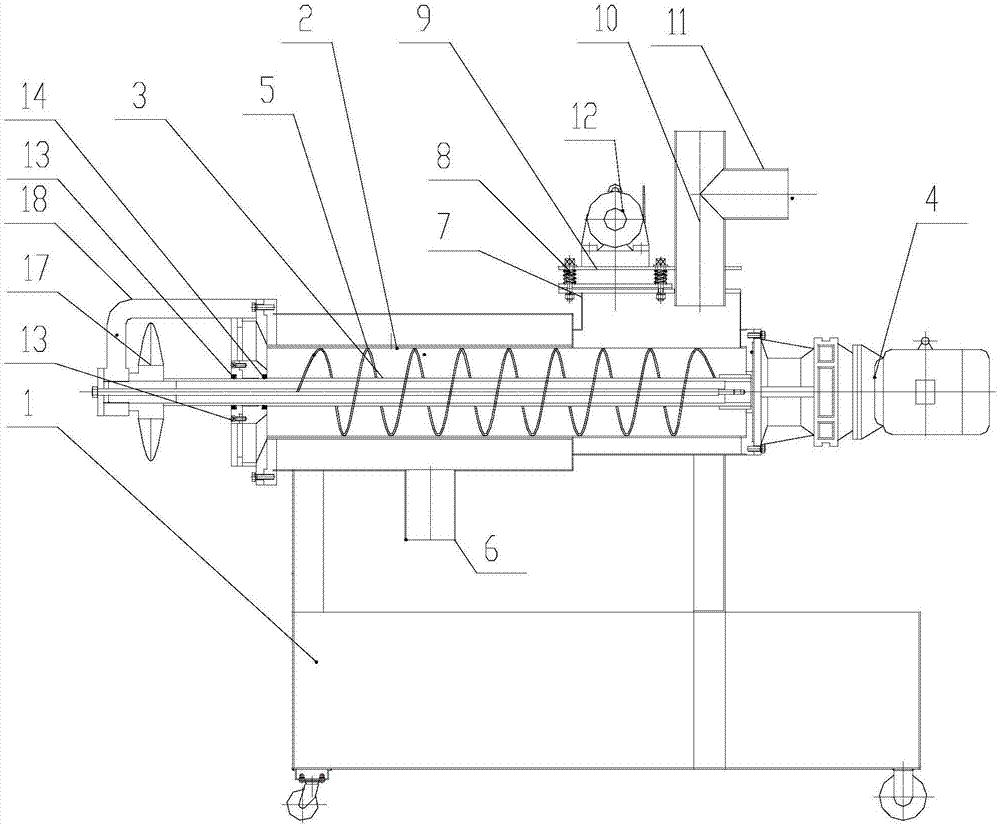

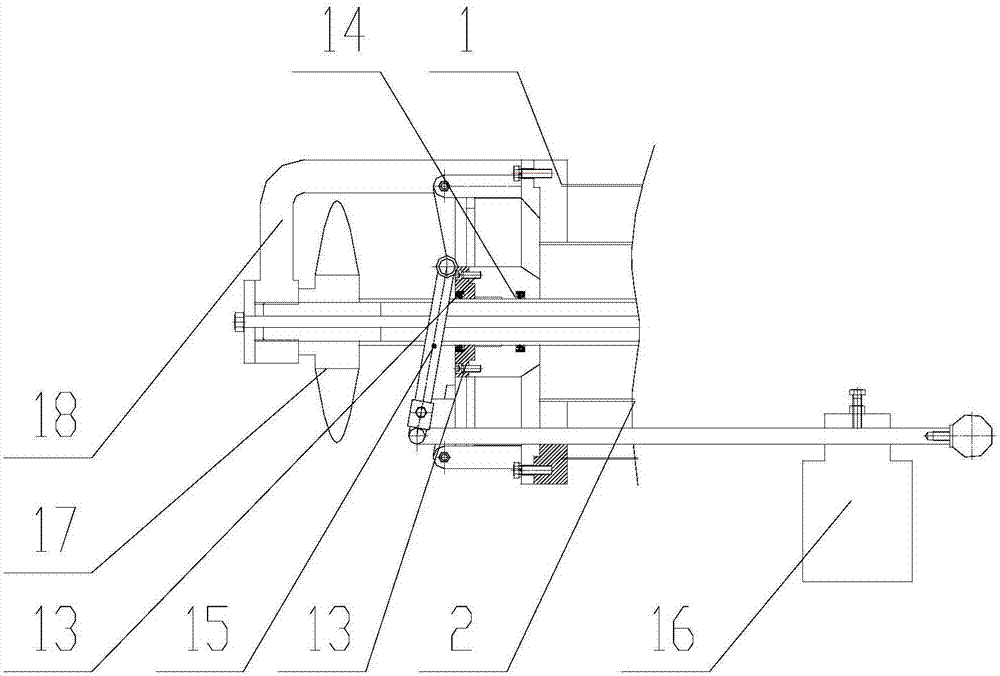

[0016] Such as Figure 1-2 As shown, the screw extruding solid-liquid separator includes a frame 1, on which a squeezing cylinder 2 is arranged, and an extruding screw 3 is installed in the squeezing cylinder 2, and a driving extruding cylinder is arranged on the frame 1. The main power device of screw rod 3, the main power device is geared motor 4. A strainer 5 is arranged on the inner wall of the squeezing cylinder 2 . The squeeze barrel 2 is provided with a material inlet and a liquid outlet 6 . The squeezing barrel 2 is provided with a mounting seat 7 at the material inlet, and the mounting seat 7 is provided with a vibrating seat 9 through four springs 8, and the vibrating seat 9 is provided with a feeding pipe 10 penetrating into the material inlet. Also be provided with overflow port 11 on 10. A vibrating motor 12 is provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com