Visual processing-based screw mounting device and screw mounting method

A technology for installing devices and screws, which can be used in measuring devices, optical devices, instruments, etc., and can solve problems such as large labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

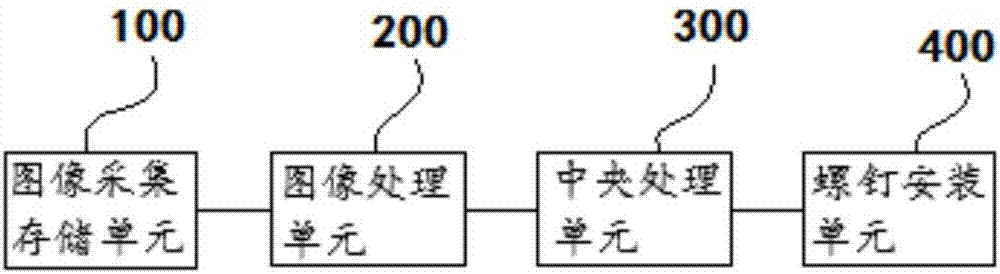

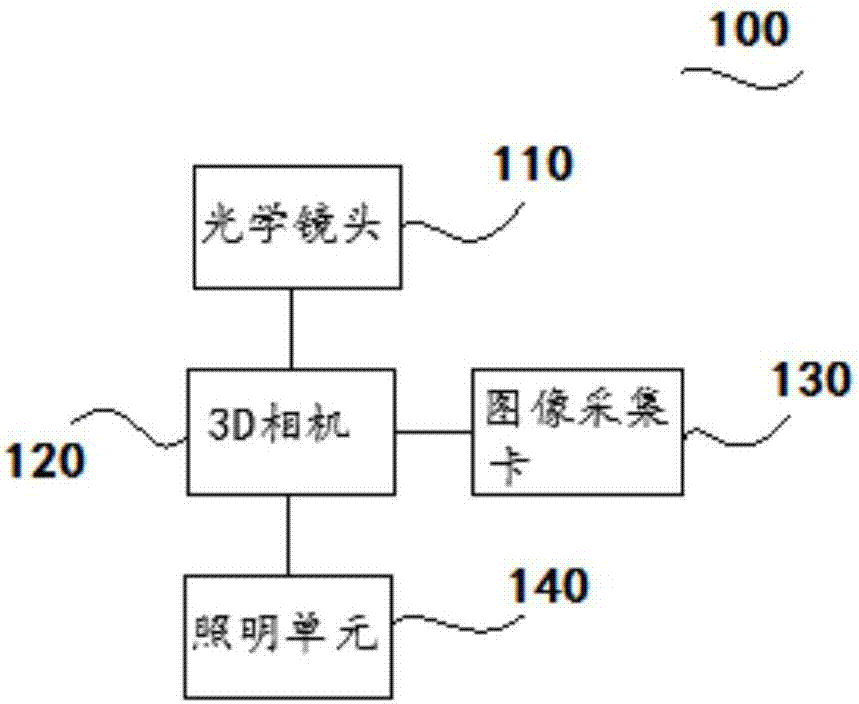

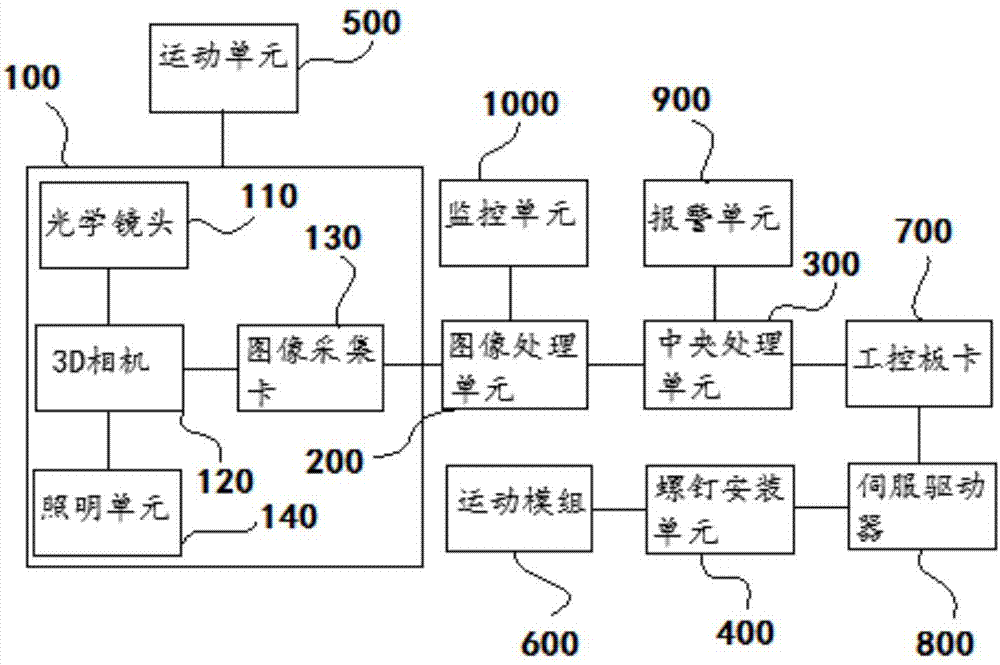

[0039] This embodiment provides a screw installation device based on visual processing, please refer to figure 1 , the screw installation device includes an image acquisition and storage unit 100 , an image processing unit 200 , a central processing unit 300 and a screw installation unit 400 .

[0040] Wherein, the image acquisition and storage unit 100 is used to acquire the image information of the screw and the spatial position of the screw hole. The image processing unit 200 is used to convert image information into digital signals. The central processing unit 300 is used for receiving digital signals and sending operation signals. The screw installation unit 400 is used for receiving an operation signal, and installing screws in corresponding screw holes according to the operation signal.

[0041] In this way, since the image acquisition and storage unit 100 can obtain the image information of the spatial position of the screw and the screw hole, it is possible to obtai...

Embodiment approach

[0071] Specifically, in order to further improve the installation accuracy of the screws, please refer to Figure 5 , another embodiment may include the following steps:

[0072] S100. Acquiring image information of the screw and the spatial position of the screw hole;

[0073] S200. Convert the image information into a digital signal;

[0074] S300. Receive the digital signal and send an operation signal;

[0075] S500. Receive the operation signal, and convert the operation signal into a specific pulse signal;

[0076] S600. Receive the pulse signal, and plan the traveling route of the screw according to the pulse signal, and install the screw in the corresponding screw hole position.

[0077] In this way, the movement trajectory of the screw can be accurately guided through the specific planning of the travel signal of the screw, and the screw can be transported to the designated screw hole position. Moreover, when the position of the screw deviates, real-time adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com