Combined wall plate

A technology for wall panels and components, applied in covering/lining, construction, building structure, etc., can solve problems such as cracking of joints, and achieve the effect of reliable installation, avoiding cracking of joints, and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

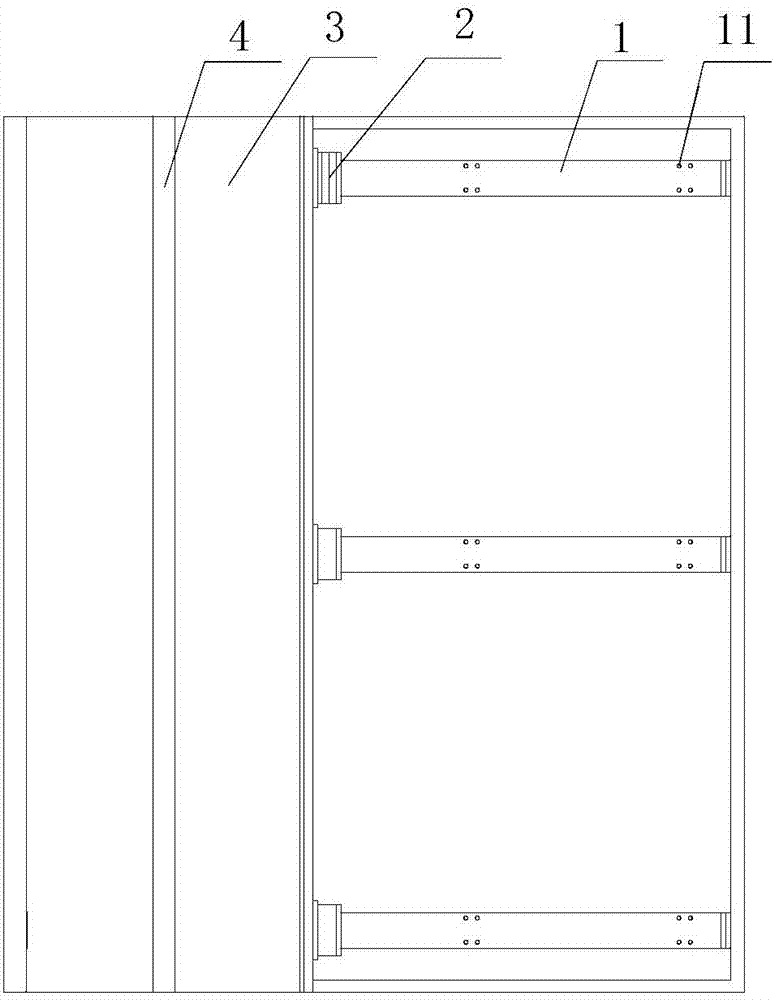

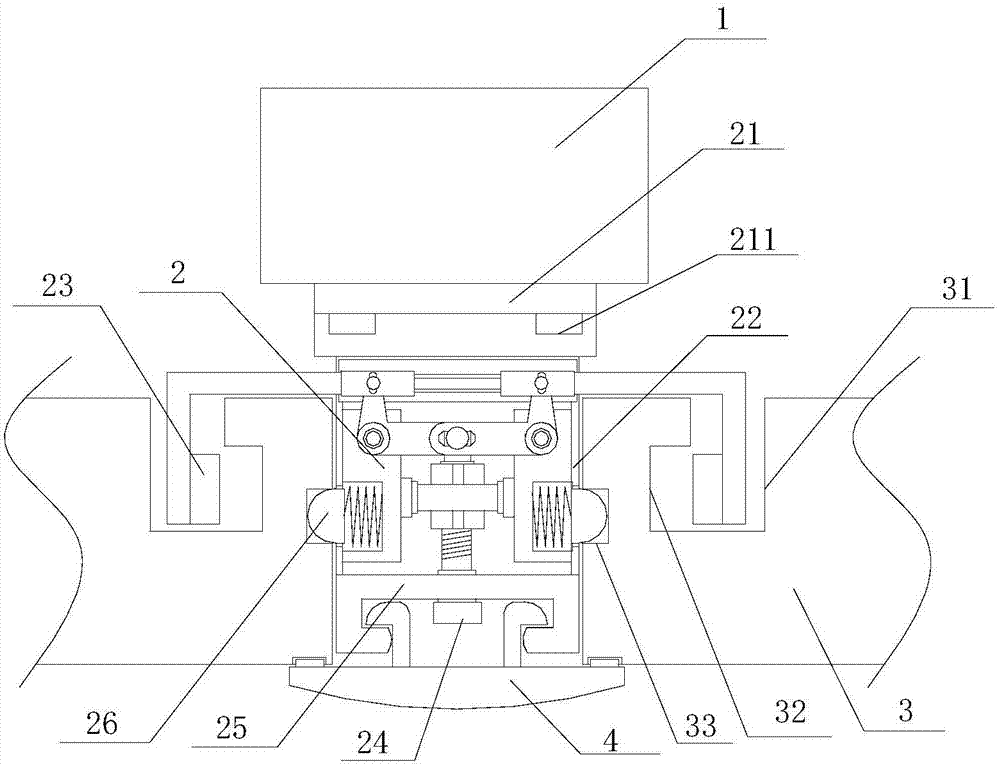

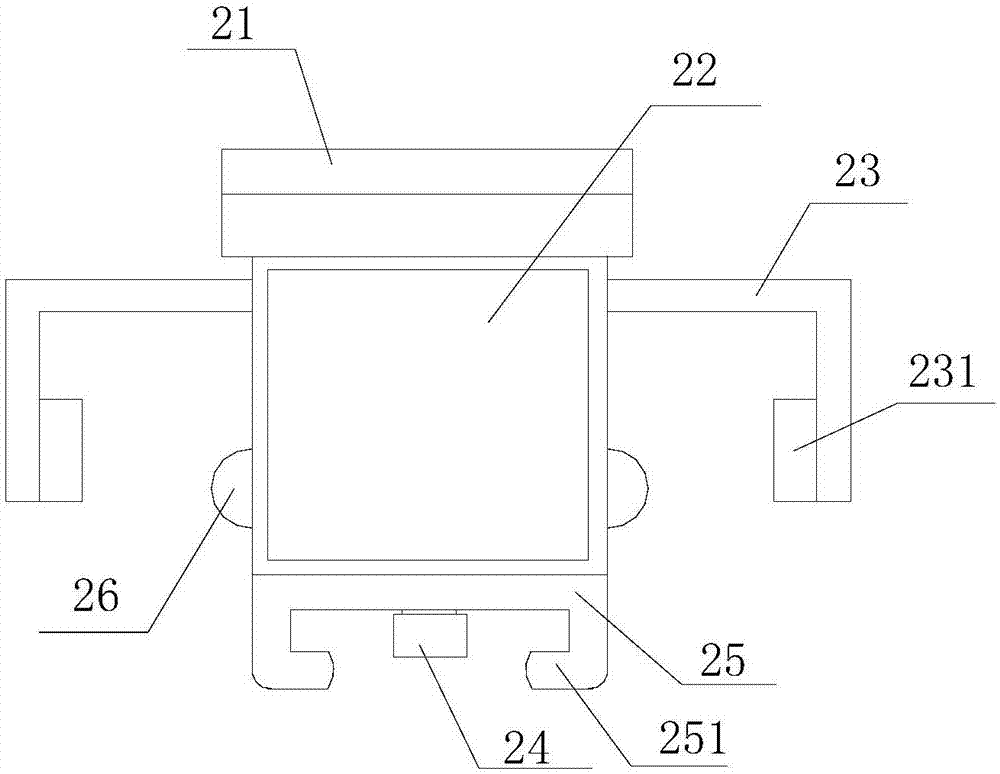

[0017] refer to Figure 1 to Figure 5 , a combined wall panel of the present invention, comprising a main joist 1, a lock assembly 2, a wall panel base material 3 and a sealing strip assembly 4, the main joist 1 is installed laterally on the wall, and the main joist 1 is installed with Several locking components 2, the wallboard base material 3 is fixed on the main keel 1 through the locking components 2, the locking components 2 are symmetrically provided with locking buckles 23, and the locking components 2 are equipped with There is a driving assembly 24, the driving assembly 24 drives the locking buckle 23 to move horizontally, the two ends of the wallboard base material 3 are provided with a first clamping groove 31, and the first clamping groove 31 is connected with the locking clamp The buckles 23 are matched, and the sealing strip assembly 4 is arranged between the wallboard substrates 3 , the locking assembly 2 is provided with a connecting buckle 25 , and the sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com