A sweeping vehicle brush lifting adjustment method

A lifting adjustment and sweeping vehicle technology, which is applied in the field of sweeping vehicles, can solve problems such as unstable circuits and inconvenient maintenance, and achieve the effects of not being prone to failure, easy operation of lifting adjustment, and stable and reliable adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

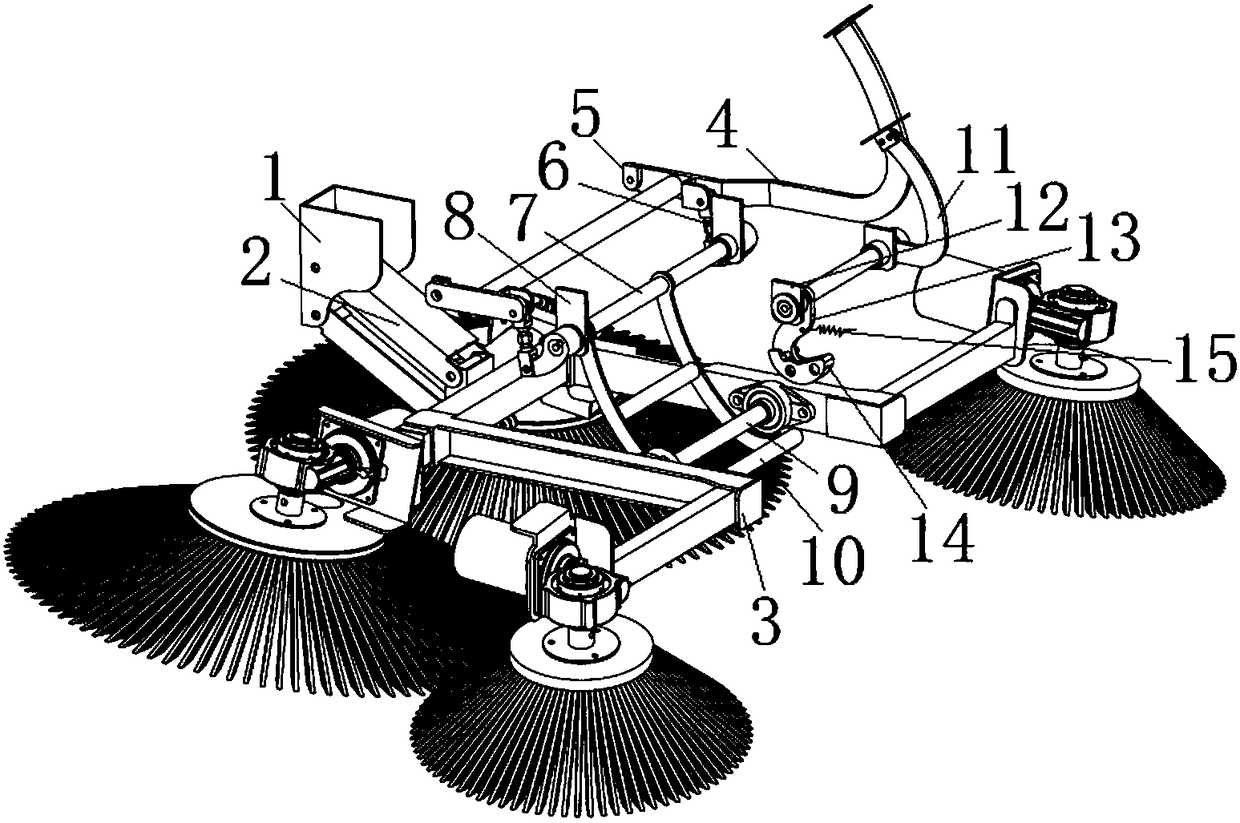

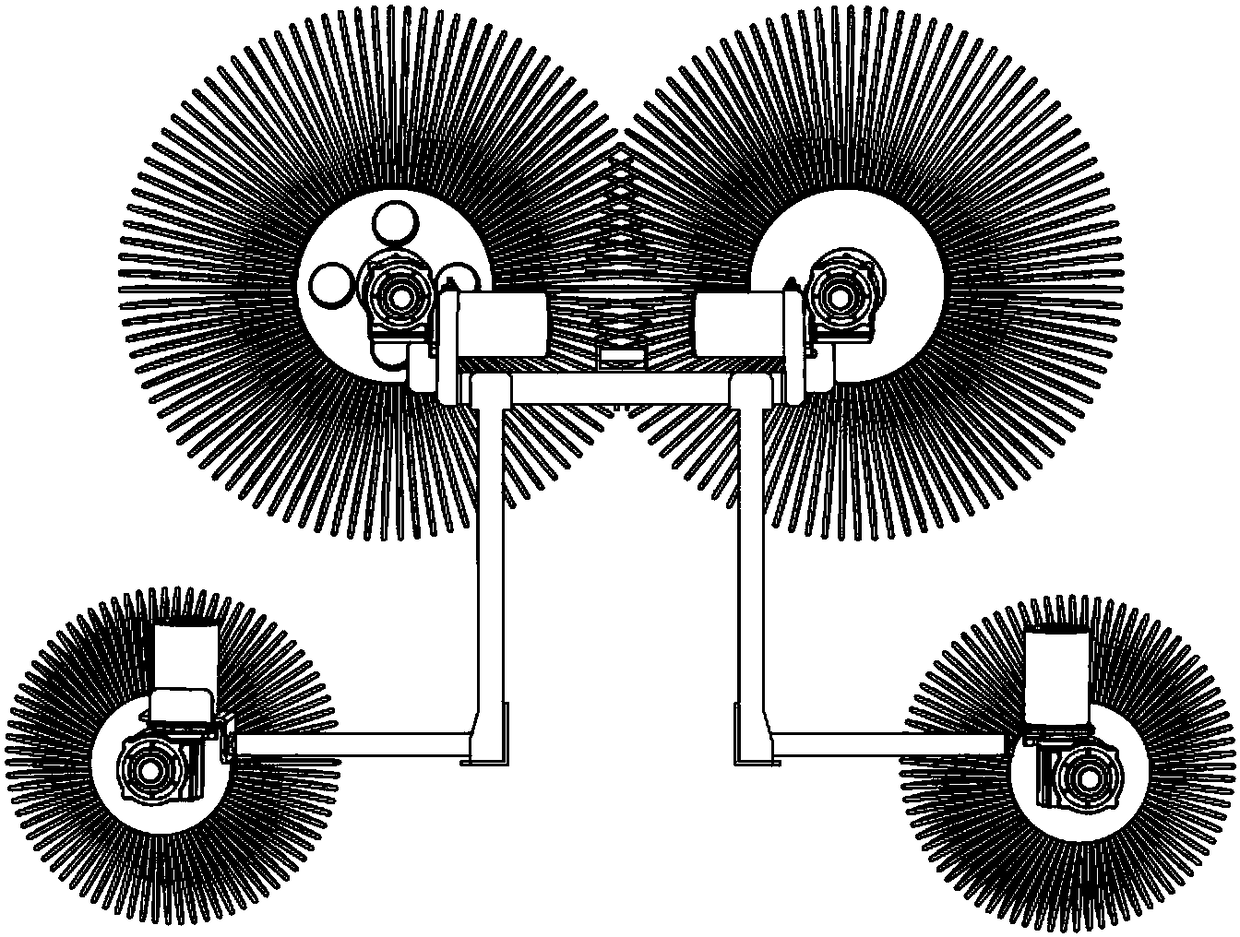

[0027] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

[0028] The brush lift adjustment method of the sweeping vehicle includes the following steps:

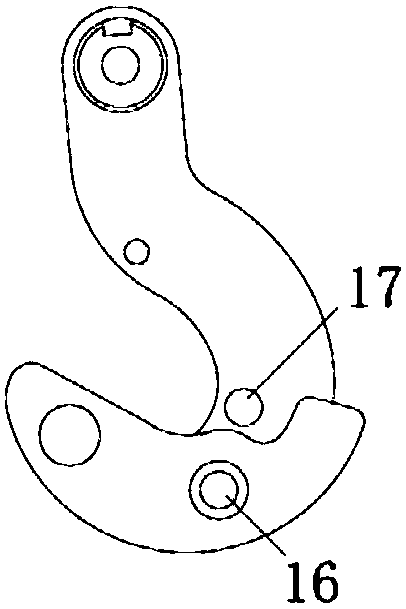

[0029] (1) The staff steps on the lowering pedal bracket, drives the hook bracket arranged on the lowering pedal bracket, and the hook on the hook bracket moves backwards so that the front axle of the lifting rod supporting the brush assembly and the front hook fall off;

[0030] (2) The lifting rod moves downward, so that the lifting beam of the brush assembly on the lifting rod falls downward, and then the brush assembly falls to the ground and reaches the working position. At this time, the descending pedal bracket loosened by the staff is reset Return to the initial position under the action of the tension spring;

[0031] (3) At the end of the work, the brush needs to be raised, and the operato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com