Construction waste color sorting equipment

A construction waste, color sorting technology, applied in sorting and other directions, can solve the problems of not very harsh production environment, equipment can not meet the requirements, etc., to achieve the effect of accurate sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

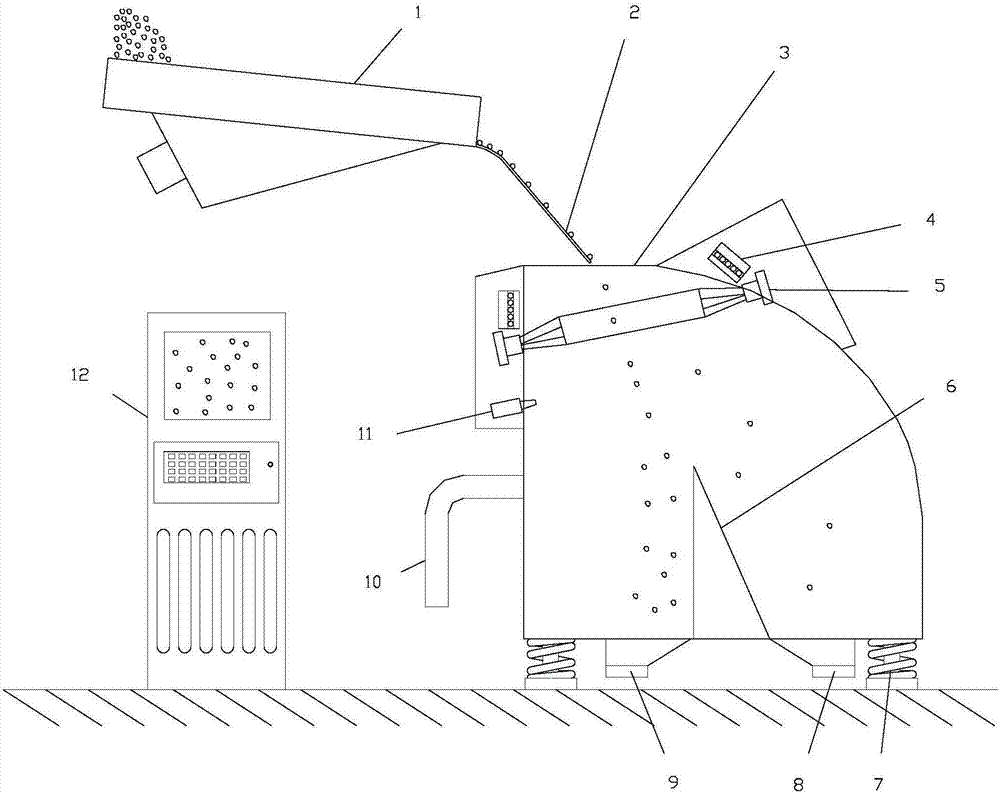

[0008] Such as figure 1 As shown, the present invention comprises feeding device, main frame 3 and control device 12, and described feeding device comprises vibrating feeding hopper 1 and chute 2, and the outlet front lower end of vibrating feeding hopper 1 is fixed chute 2, and the bottom of chute 2 is opposite to Accurate the feed inlet of described main frame 3; Fix light source 4, high-speed camera 5 and nozzle 11 near the feed inlet inner wall of described main frame 3, light source 4, high speed camera 5 and nozzle 11 and described control device 12 electrical connection, the inner bottom of the main box 3 is fixed with a partition plate 6, and the partition plate 6 can separate the crushed material sprayed by the nozzle 11 from the feed port of the main box 3, and the inner bottom plate of the main box 3 at both ends of the partition plate 6 There are light and heavy broken material outlets 8,9 respectively on the top.

[0009] The bottom of the main chassis 3 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com