System for producing natural gas from coke oven gas

A coke oven gas and natural gas technology, which is applied in the removal of gas pollutants, gas fuel, gas treatment, etc., can solve the problems of high energy consumption and large investment, and achieve low energy consumption, low investment, and reduced gas consumption costs Effect

Inactive Publication Date: 2017-10-20

湖北和远气体股份有限公司

View PDF1 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The invention patent "Method for Extracting Methane from Coke Oven Gas by Membrane Separation and Low-Temperature Rectification" (CN 101747132) is an advanced treatment method for coke oven gas, which uses membrane separation technology and low-temperature rectification technology to extract methane, which requires a large investment , high energy consumption, and its product is liquefied natural gas

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited to the scope expressed in the examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

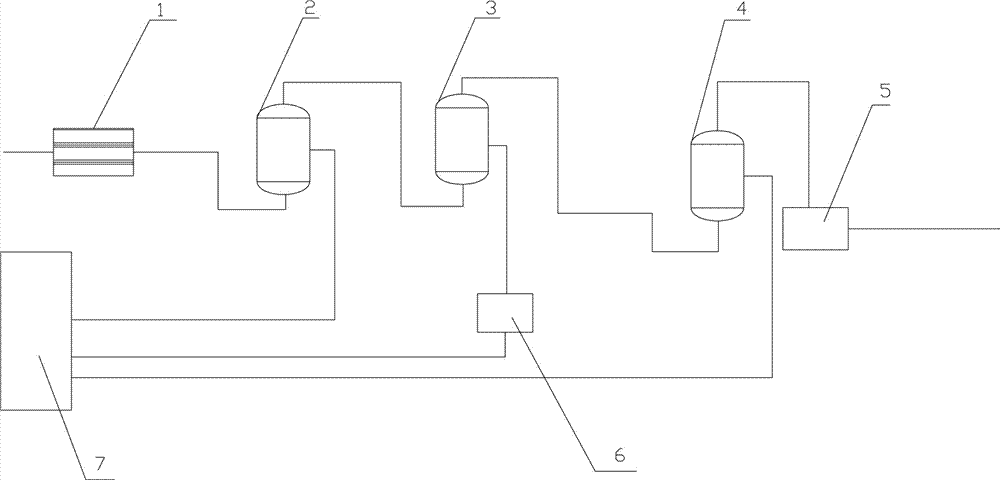

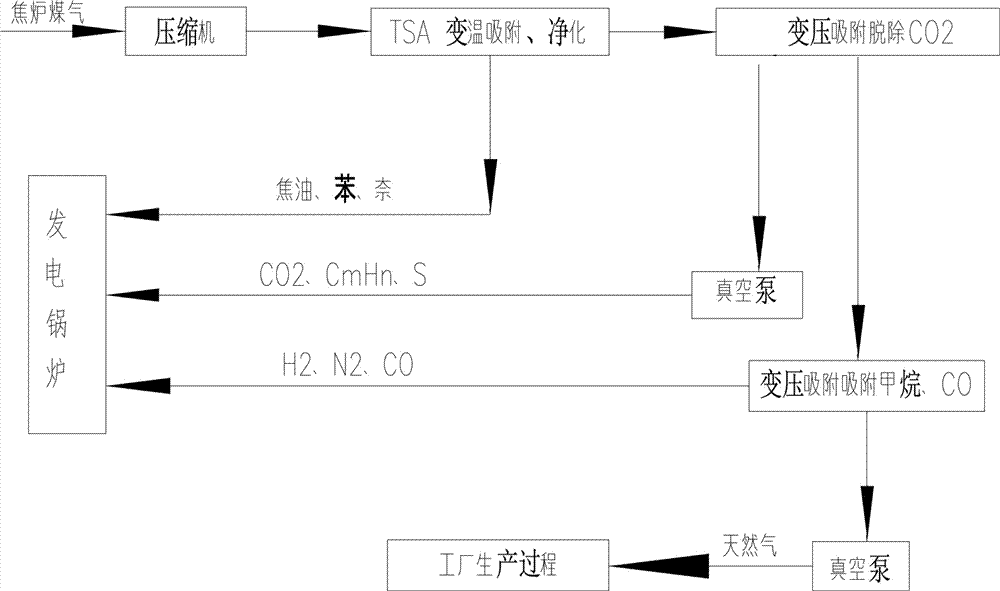

The invention relates to the field of comprehensive utilization of coke oven gas, in particular to a system for producing natural gas from coke oven gas. The system comprises a compressor, wherein the compressor is connected with a temperature swing adsorption device through a pipeline, the temperature swing adsorption device is connected with a first pressure swing adsorption device through a pipeline, the first pressure swing adsorption device is connected with a second pressure swing adsorption device through a pipeline, and the second pressure swing adsorption device is connected with a first vacuum pump through a pipeline; the first pressure swing adsorption device is connected with a second vacuum pump through a pipeline. The temperature swing adsorption device, the second pressure swing adsorption device and the second vacuum pump are connected with a power generating boiler through pipelines. Residual gas after extraction of natural gas is not treated further and used for generating power, the coke oven gas is treated with the pressure swing adsorption method for extraction of the natural gas, and the total energy consumption of the device is low.

Description

technical field [0001] The invention relates to the field of comprehensive utilization of coke oven gas, in particular to a system for producing natural gas from coke oven gas. Background technique [0002] Most existing steel mills will be equipped with a coking plant, which produces coke for the ironmaking process of the steel mill, and a large amount of coke oven gas will be produced during the coking process of the coking plant. At the same time, many processes in steel mills (such as hot rolling, cold rolling, and heat treatment) need to use natural gas with high calorific value. [0003] In the prior art, the coke oven gas produced in the coking plant is generally used to heat the boiler to generate steam, and the steam drives the steam turbine generating set to generate electricity. Because heat treatment and other processes have high requirements on the calorific value of gas, natural gas is purchased from outside for heat treatment. The invention patent "Method fo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D53/04B01D53/047C10L3/10C10K1/32

CPCB01D53/0462B01D53/047B01D2256/245B01D2257/504B01D2257/70B01D2257/7027B01D2259/4009C10K1/002C10K1/004C10K1/005C10K1/32C10L3/101C10L3/104C10L3/105C10L2290/542Y02C20/40

Inventor 杜大艳杨涛焦文艺

Owner 湖北和远气体股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com