Vacuum heat insulation body

一种真空隔热体、真空排气的技术,应用在通过隔热保护管道、热交换设备、制冷装置隔离等方向,能够解决难以实现实用化、连续气泡聚氨酯泡沫排气阻力大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

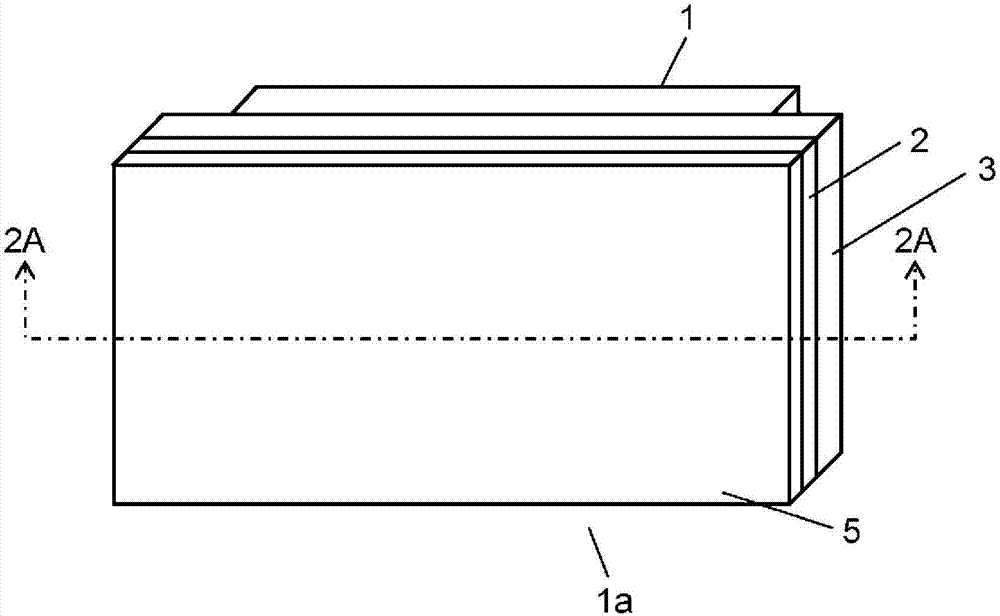

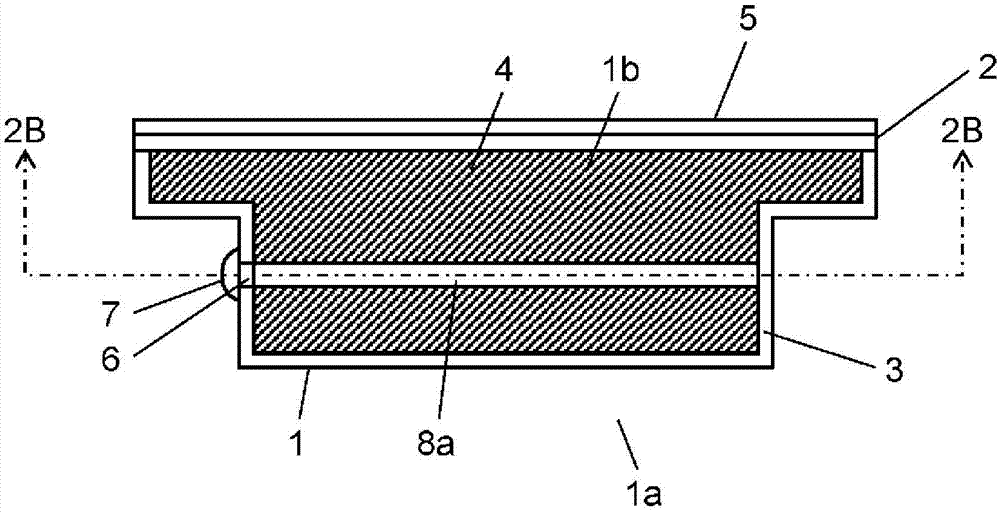

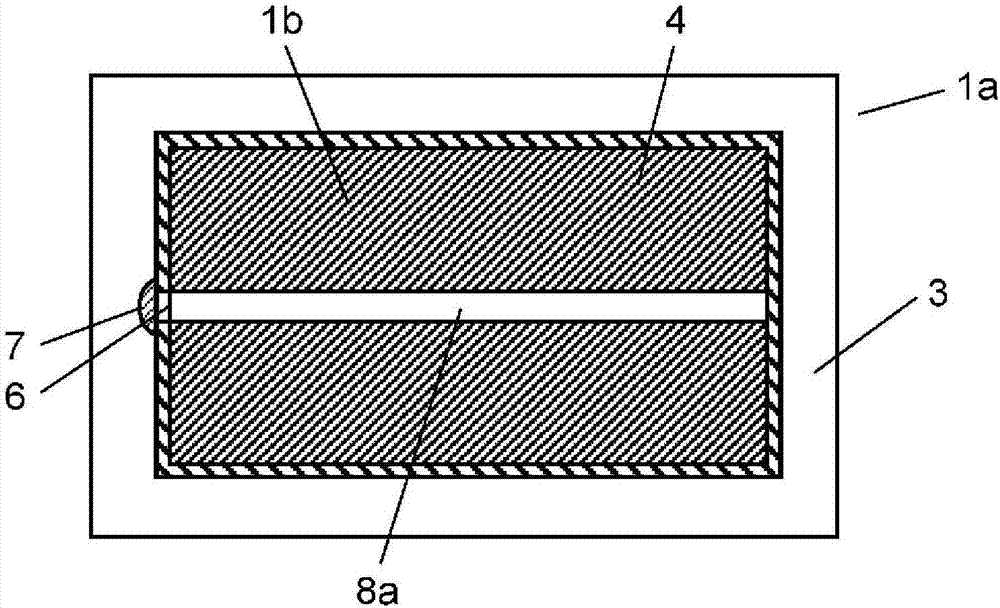

[0050] figure 1 It is a perspective view of the refrigerator door 1a including the vacuum heat insulating body (Hereinafter, a box-shaped vacuum heat insulating body is also called a vacuum heat insulating box) 1 which concerns on Embodiment 1 of this invention. Figure 2A yes figure 1 A sectional view of line 2A-2A of the refrigerator door 1a shown, Figure 2B yes Figure 2A A cross-sectional view of line 2B-2B.

[0051] Such as Figure 2A As shown, the vacuum heat insulating body 1 of this embodiment has a box shape (henceforth the vacuum heat insulating body 1 or the vacuum heat insulating box 1). Refrigerator door 1a is provided with appearance member 5 formed of glass, metal, etc., and vacuum heat insulation box 1 on the surface. The vacuum heat-insulating box 1 has an outer case 2 made of a gas-barrier material, an inner case 3 also made of a gas-barrier material, and continuous air bubbles filling a heat-insulating space 1b between the outer case 2 and the inner case...

Embodiment approach 2

[0093] The vacuum heat insulation box 1 according to Embodiment 2 of the present invention includes figure 1 The external shape of the refrigerator door 1a of the vacuum heat insulation box 1 of Embodiment 1 shown is the same.

[0094] Figure 9A It is a sectional view showing the vacuum heat insulation box 1 of this embodiment, and is figure 1 It is a sectional view of line 2A-2A of the shown refrigerator door 1a. Figure 9B yes Figure 9A Sectional view of line 9B-9B.

[0095] In this embodiment, the continuous cell urethane foam 4 is foamed in the entire inside of the vacuum heat insulating box 1 . Similar to Embodiment 1, the vacuum heat insulating box 1 of this embodiment has an outer case 2 made of a gas-barrier material, an inner case 3 similarly made of a gas-barrier material, and the outer case 2 and inner case 3 filled with The open-cell polyurethane foam 4 (core material of the vacuum heat insulation layer) is used for the heat insulation space 1b between them....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com