A vane type oscillating hydraulic cylinder with a fully enclosed cage seal system

A technology of sealing system and hydraulic cylinder, applied in the direction of fluid pressure actuating device, mechanical equipment, etc., can solve the problems of difficult sealing, leakage of sealing performance, and complexity, so as to avoid oil pressure loss, increase working oil pressure, reduce or the effect of oil pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

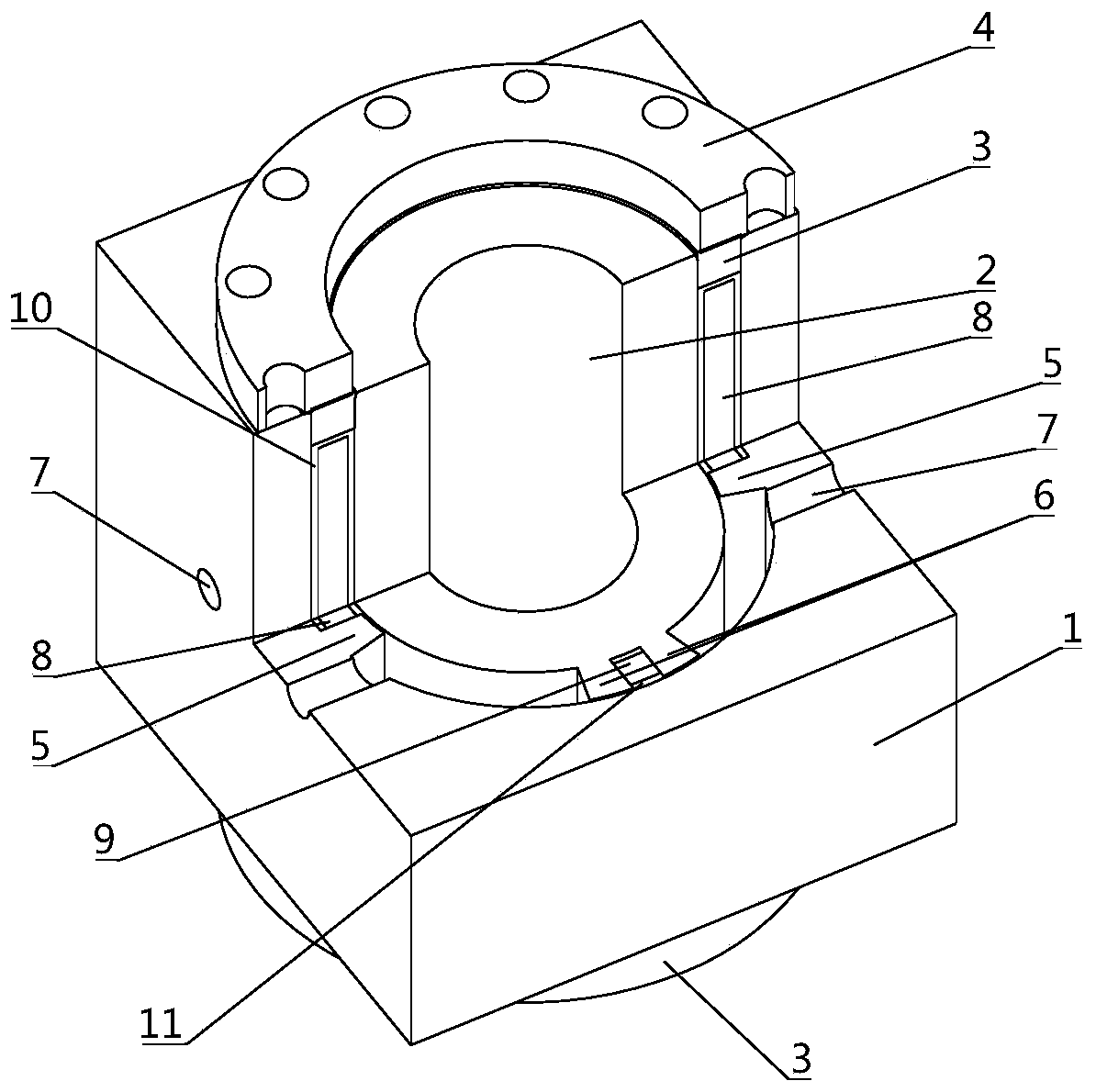

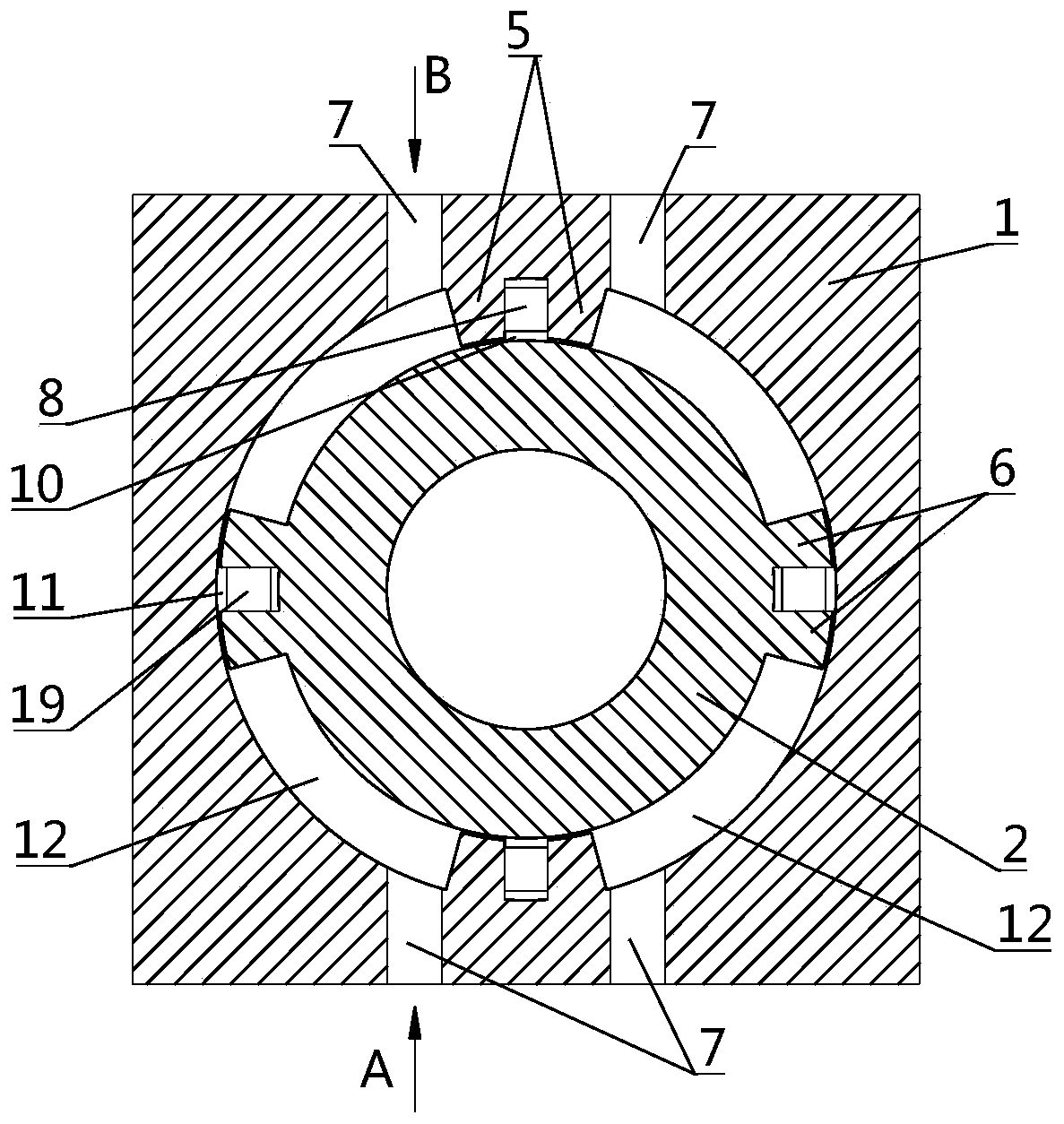

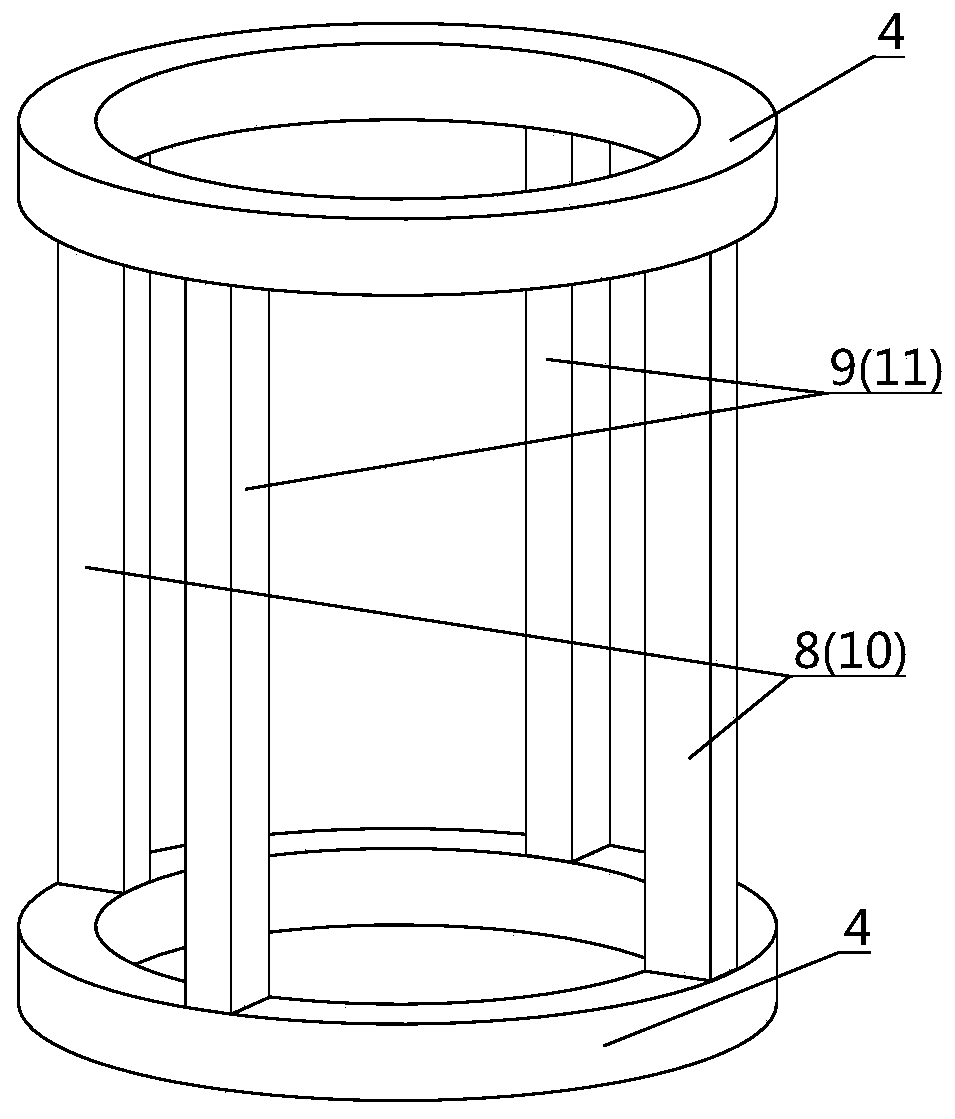

[0018] pass below Figure 1 ~ Figure 2 And the way of enumerating some optional embodiments of the present invention, the technical solution of the present invention (including the preferred technical solution) is described in further detail, and any technical feature and any technical solution in this embodiment do not limit the protection scope of the present invention .

[0019] Such as figure 1 and figure 2 As shown, the vane-type swing hydraulic cylinder with a fully enclosed cage-type sealing system disclosed in this embodiment includes a stator 1 and a rotor 2, the rotor 2 is located inside the stator 1, and an annular cavity is provided between the rotor 2 and the stator 1; The top outer wall at both ends of the rotor 2 is provided with an end face seal 3 that seals the rotation of the top outer wall of the rotor 2 and the inner wall of the stator 1; the cover plate 4 is fixed to the stator 1, and the end face seal 3 abuts on the cover plate 4 to prevent the rotor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com