Horizontal type air cooling refrigerator

A horizontal, air-cooled technology, applied in the field of refrigeration equipment, can solve the problems of unsmooth circulation of cold air, unbalanced cooling capacity distribution, poor cooling effect, etc., to achieve balanced cooling capacity distribution, reduce heat loss, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

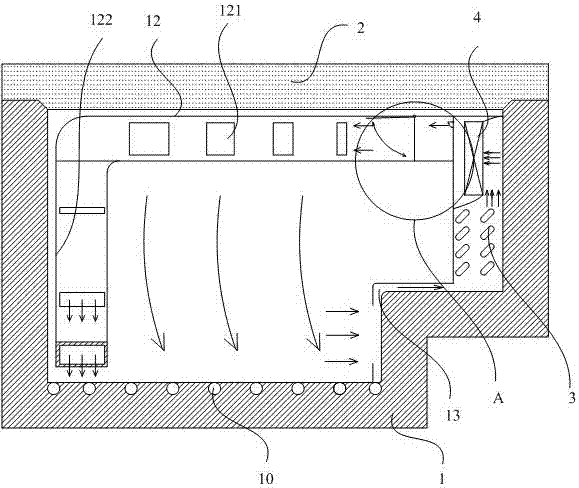

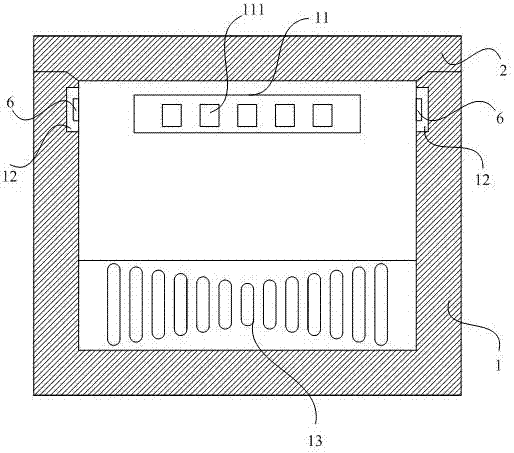

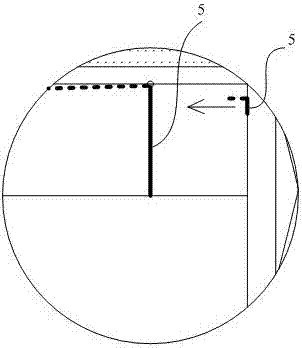

[0029] Such as Figure 1-Figure 8 As shown, the horizontal air-cooled freezer in this embodiment includes a horizontal cabinet body 1 and a door body 2. The horizontal cabinet body 1 is provided with an evaporation chamber, and the evaporation chamber is provided with a fan 4 and an evaporator. 3. One end of the horizontal cabinet body 1 is provided with an end air outlet duct 11 and an air return duct 13 arranged up and down, and the two side walls of the horizontal cabinet body 1 are respectively provided with side air outlet ducts 12, The end air outlet channel 11 and the side air outlet channel 12 are respectively connected to the air outlet of the evaporation chamber, and the return air channel 13 is connected to the air inlet of the evaporation chamber; The air duct 12 is horizontally provided with a plurality of first jet ports 121, and the end air outlet duct 11 is provided with at least one second jet port 111, and the air outlet directions of the first jet port and t...

Embodiment 2

[0036] Based on the first embodiment above, optional, such as Figure 9 As shown, the horizontal cabinet body 1 is provided with an organic compartment in which a compressor 10 is arranged, and a water receiving tray 7 is also arranged in the machine compartment, and a drainage channel 71 connected to the water receiving tray 7 is opened at the bottom of the evaporation chamber. , the water receiving tray 7 is also provided with a humidification channel 72 communicating with the upper part of the evaporation chamber, the drainage channel 71 is provided with a first valve (not marked), and the humidification channel 72 is provided with a second valve (not marked). Specifically, the evaporation chamber is connected to the water receiving tray 7. During the defrosting process, the first valve is opened, and the frost layer on the evaporator 3 is heated to form defrosting water, and the defrosting water flows into the water receiving tray 7 through the drainage channel 71. During ...

Embodiment 3

[0039] Based on the first embodiment above, optional, such as Figure 10 As shown, the horizontal cabinet body 1 is provided with an organic compartment, in which a compressor 10 is arranged, and a drainage channel 71 connected to the water receiving tray 7 is opened at the bottom of the evaporation chamber, and a drain valve (not marked) is arranged in the drainage channel 71 The return air channel 13 is also connected with a bypass air channel 8 for communicating with the evaporation cavity, and the connection between the bypass air channel 8 and the return air channel 13 is provided with a switching valve for switching and opening the return air channel 13 and the bypass air channel 8 ( unmarked), the air drying module 81 is connected to the bypass air passage 8, and the humidity sensor (not shown) linked with the switching valve is arranged in the horizontal cabinet body 1 . Specifically, in order to facilitate defrosting and reduce user operations, the evaporation chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com