Working method of high-efficiency spot welding equipment for metal material machining

A high-efficiency spot and metal material technology, applied in metal processing equipment, welding equipment, auxiliary welding equipment, etc., can solve the problem of inability to monitor the working status of spot welding manipulators and clamping mechanisms in real time, and to ensure the efficient and stable operation of the equipment. Work is prone to deviations and other problems, so as to shorten the time of intermediate pauses, improve safety and accuracy, and ensure health and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

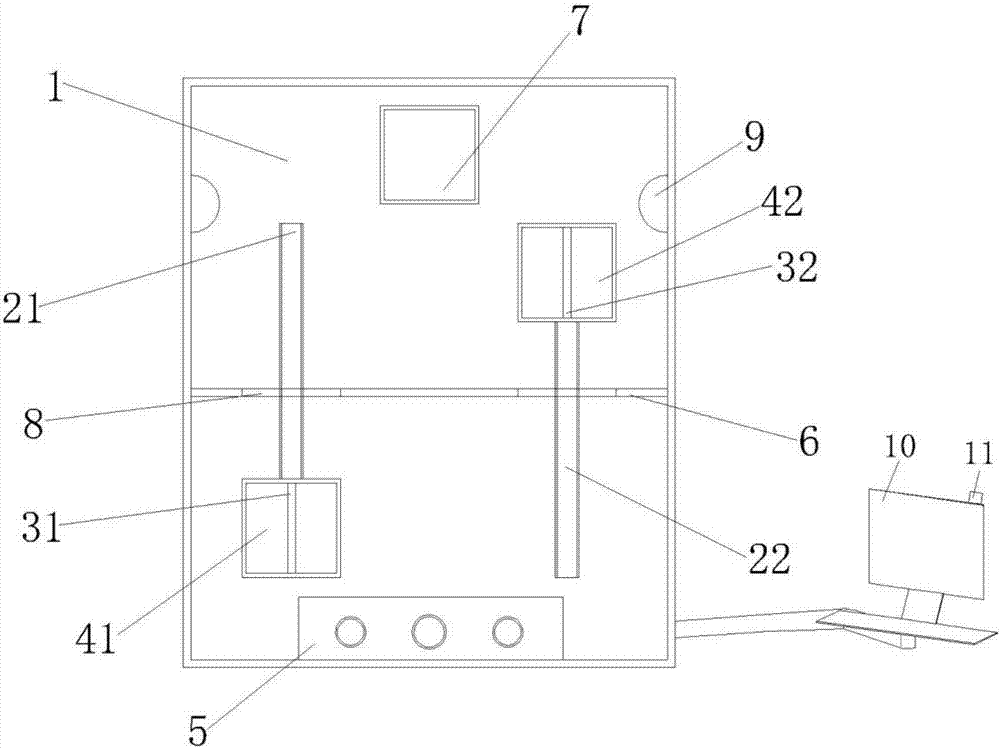

[0026] Such as figure 1 As shown, a kind of working method of high-efficiency spot welding equipment for metal material processing of the present embodiment, the specific working steps are as follows:

[0027] (1), firstly start the power switch, the staff set the working parameters through the electrical control panel 5, the first automatic clamping mechanism 41 starts to slide on the first guide rail 21 through the first slide bar 31 after clamping the workpiece to be processed ;

[0028] (2), when the first automatic clamping mechanism 41 slides to the top, the spot welding manipulator 7 moves to the left to start spot welding the workpiece to be processed, and at the same time, the second automatic clamping mechanism 42 passes through the second automatic clamping mechanism 42 after clamping the workpiece to be processed. Two slide bars 32 start to slide on the second guide rail 22;

[0029] (3) After the spot welding of the workpiece clamped by the first automatic clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com