Aluminum plastic film shell forming device and using method thereof

A forming device and aluminum-plastic film technology, which is applied in the field of aluminum-plastic film shell forming devices, can solve problems such as high processing precision requirements, aluminum-plastic film breakage, tearing, and reduced battery safety, and achieve low matching precision requirements , The risk of battery damage is reduced, and the number of times of cleaning and maintenance is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

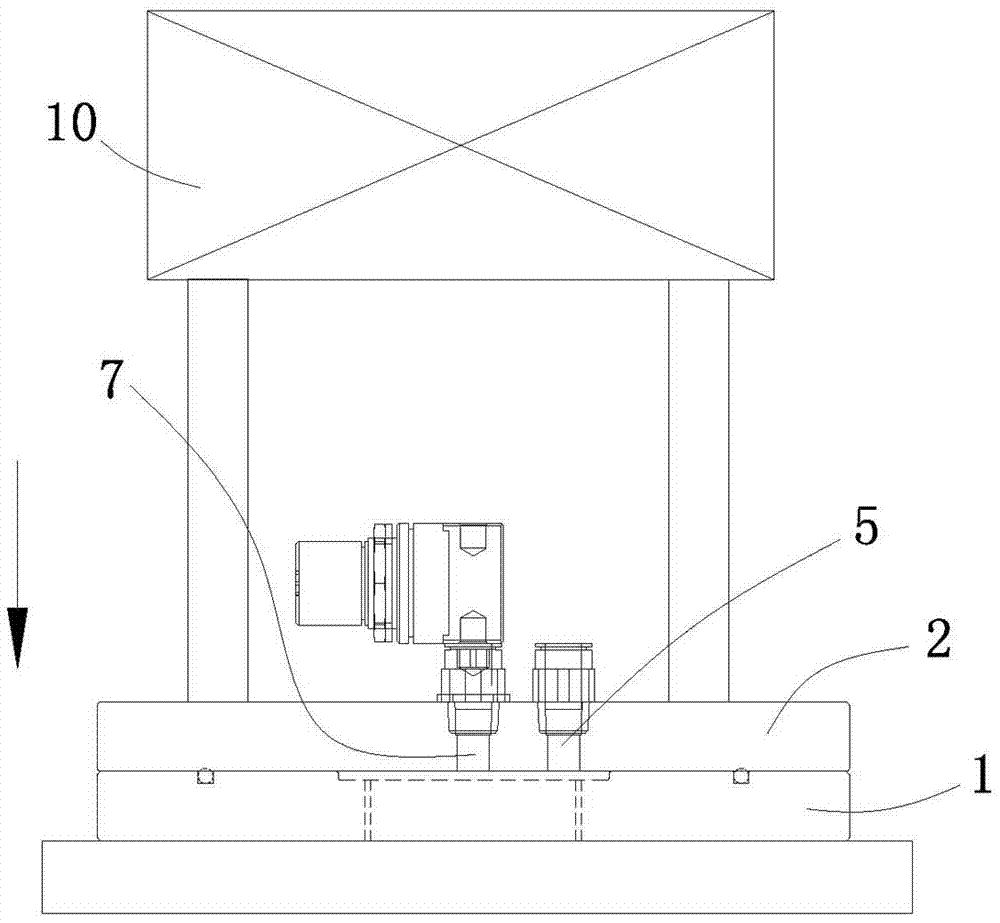

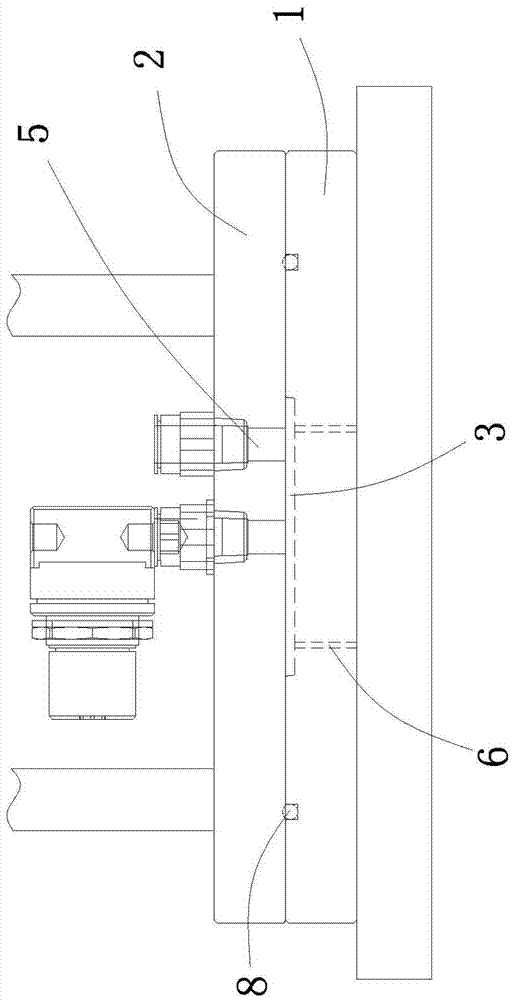

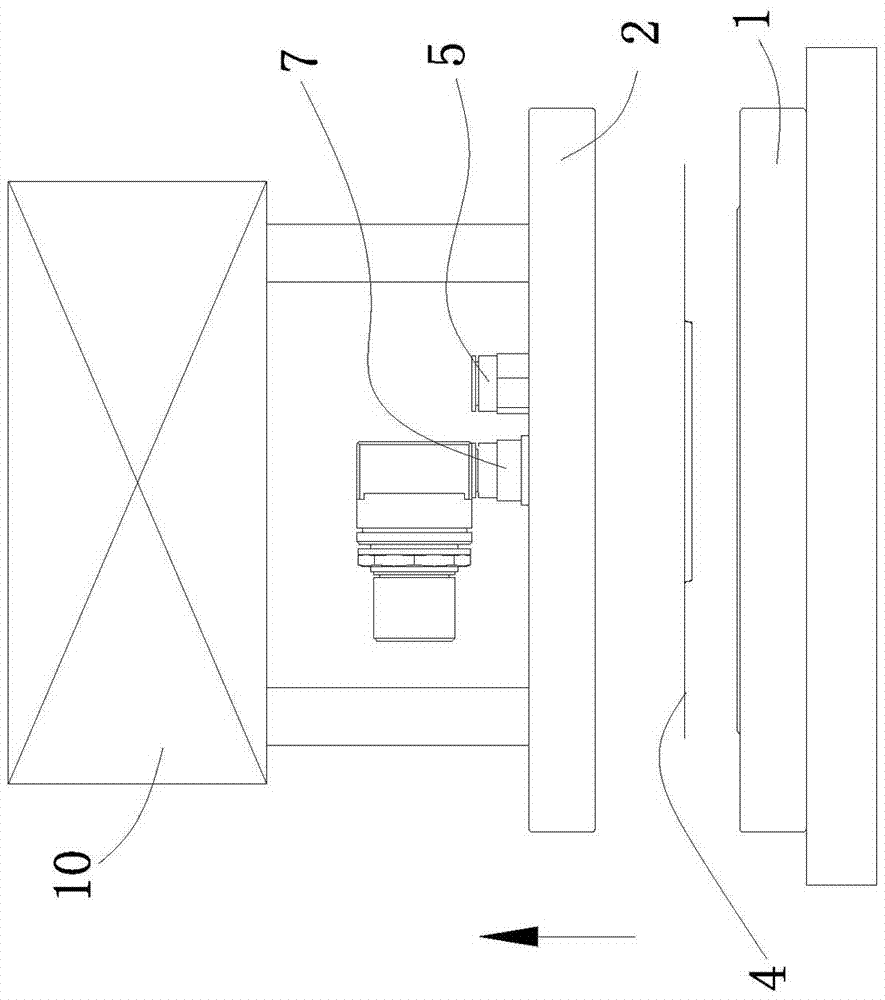

[0032] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] to combine Figure 1 to Figure 3 , The aluminum-plastic film shell forming device provided by the present invention includes a concave template 1 and a pressure plate 2 . The concave template 1 is fixedly arranged, and the top surface of the concave template 1 is used for placing the aluminum-plastic film 4 . The top surface of the concave template 1 has a pit 3 (see figure 2 ), the pit 3 of the concave template 1 corresponds to the shape of the depression that the aluminum-plastic film 4 needs to form. The pressing plate 2 is slidably arranged above the concave formwork 1 up and down, and the pressing plate 2 can slide to cover the top surface of the concave formwork 1 . The pressing plate 2 and the concave template 1 can press the aluminum-plastic film 4 together, so that a closed cavity is formed between the pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com