Automatic quantitative timed feeding cleaning device

A technology of timing feeding and cleaning device, applied in the field of animal husbandry, can solve the problems of endangering the safety of livestock or poultry, fighting for livestock or poultry, stacking together, etc., to achieve the effect of timing and quantitative feeding, and facilitating time and quantity control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

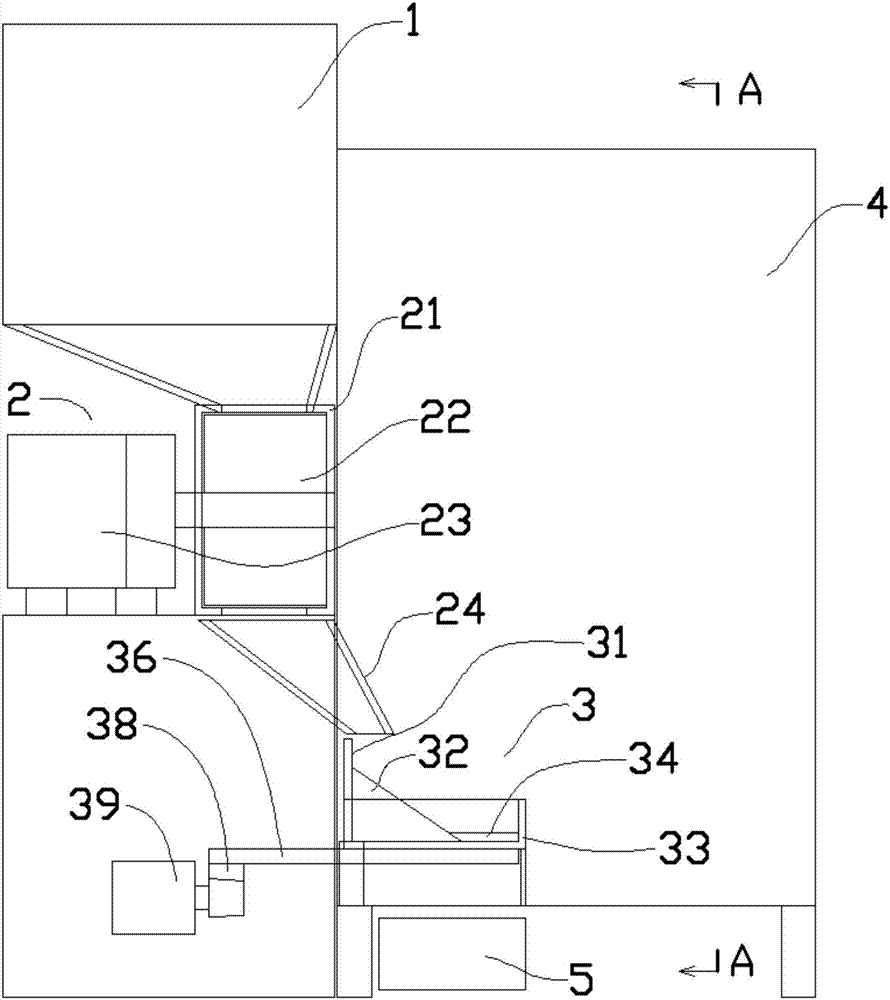

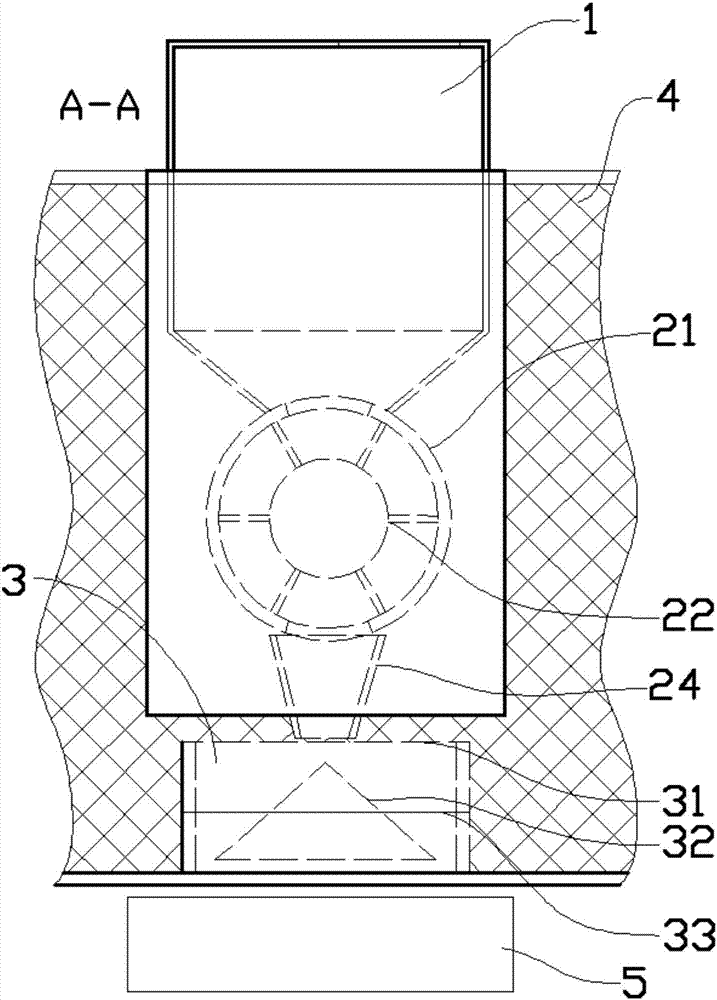

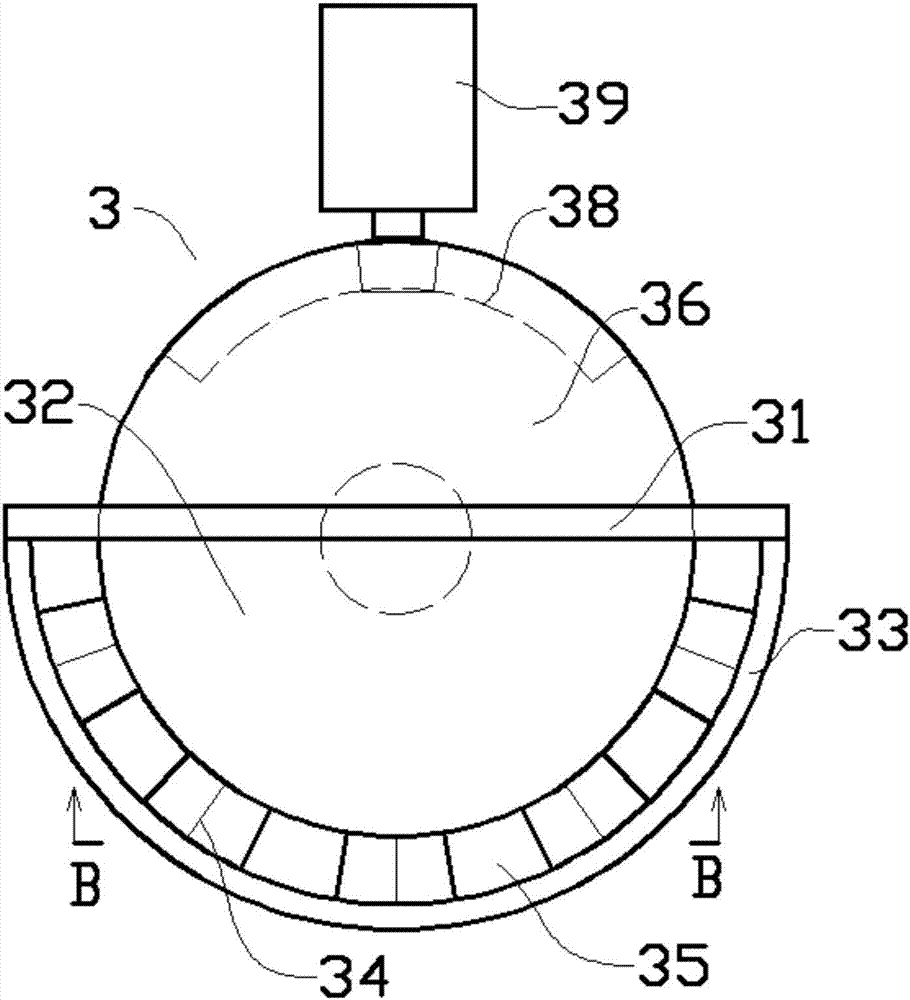

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0018] like Figure 1 to Figure 5 As shown in the embodiment, the automatic quantitative and timing feeding and cleaning device includes a main hopper 1, a feeder 2, and a trough 3; Cavity, the cylindrical cavity of the housing is equipped with a material distribution impeller 22, the material distribution impeller 22 includes a rotating shaft that is rotatably assembled with both ends of the cylindrical cavity, and the circumference of the rotating shaft is evenly distributed with shafts parallel to the axis of the cylindrical cavity The blade, the gap between the side of the blade away from the rotating shaft and the annular inner wall of the cylindrical cavity is less than 5mm, which can also prevent the material particles from being exposed from the gap. One side shaft end of the rotating shaft protrudes from the casing 21 and is connected to the discharge mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com