Method and device for preparing golden finger circuit board

A gold finger and circuit board technology, which is applied in the field of gold finger circuit board preparation, can solve the problems of easily appearing white layer board edge burrs, low production efficiency, high production cost, etc., to improve the large burr on the edge of the board and improve the shape processing , to avoid the effect of low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be described in detail below through the accompanying drawings and specific embodiments. It should be understood that the embodiments of the present invention and the specific technical features in the embodiments are only descriptions of the technical solutions of the present invention, rather than limitations. , the embodiments of the present invention and specific technical features in the embodiments may be combined with each other.

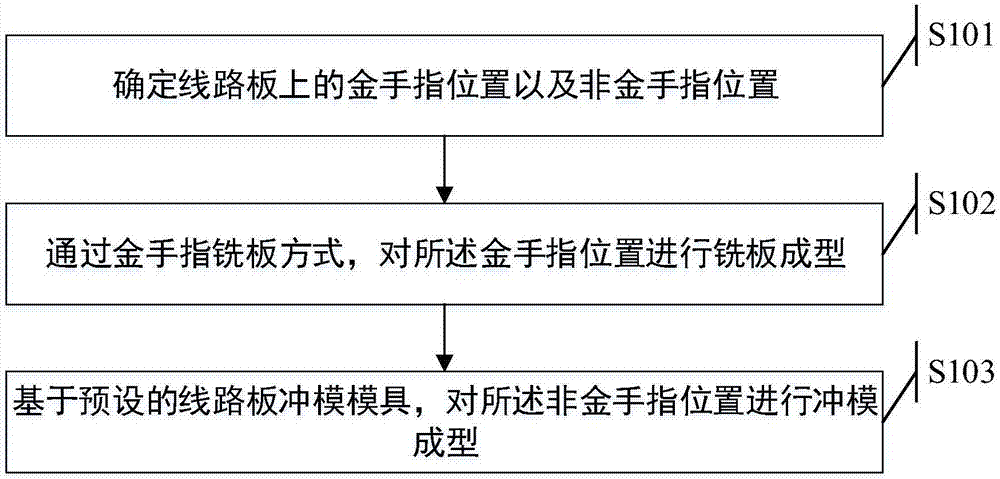

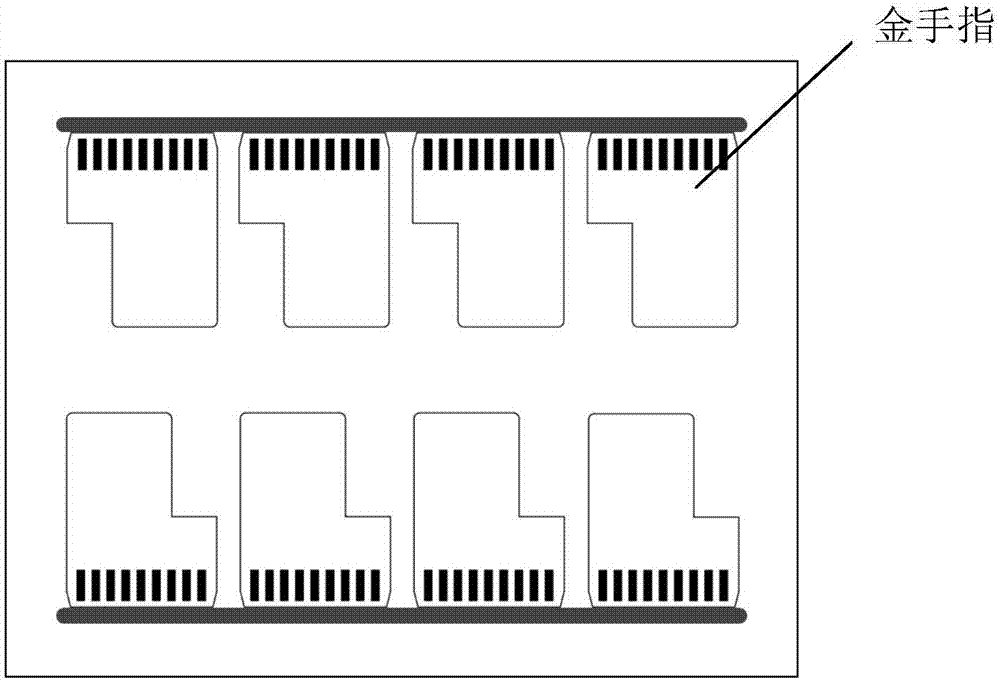

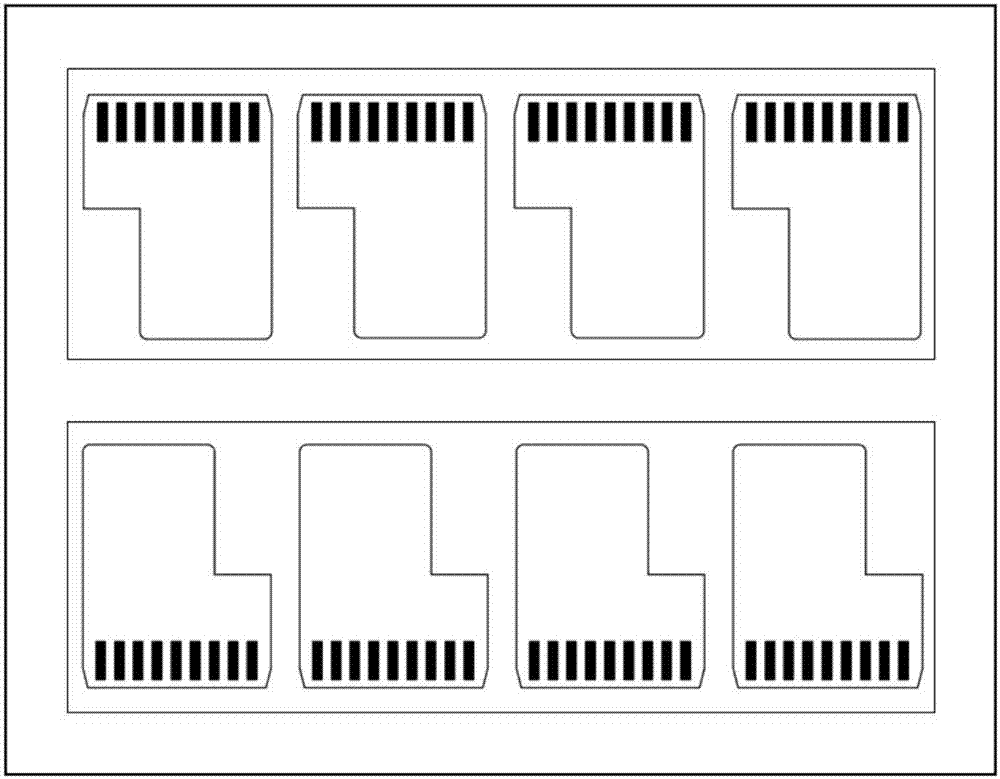

[0034] like figure 1 Shown is a flow chart of a method for preparing a golden finger circuit board in an embodiment of the present invention, the method comprising:

[0035] S101, determining the positions of gold fingers and non-gold fingers on the circuit board;

[0036] S102, milling and forming the position of the gold finger by means of gold finger milling;

[0037] S103. Perform die forming on the non-finger position based on the preset circuit board die.

[0038] Specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com