Goods partition delivery part, shipment mechanism and shipment system

A cargo separation and component technology, which is applied to coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items, etc. The number of goods, the inability to reasonably optimize the shipment arrangement, the inability to orderly and accurately ship the goods, etc., to achieve the effect of solving the problem of goods adaptability, reducing the number of motors used, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

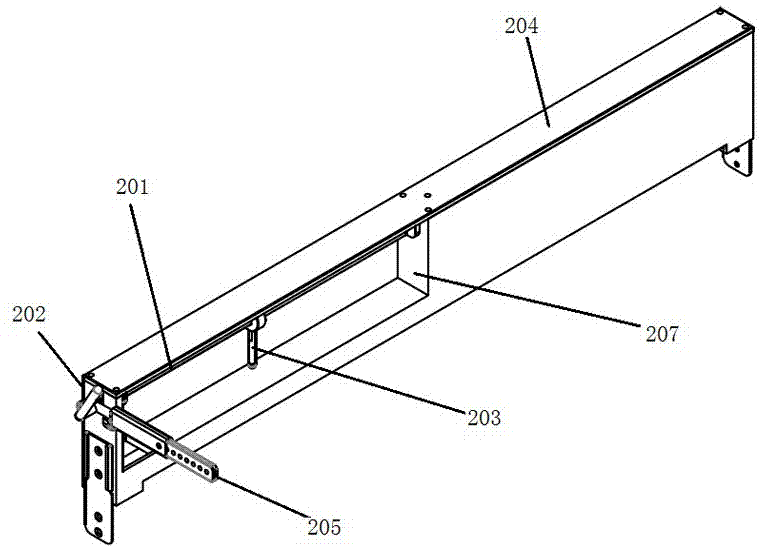

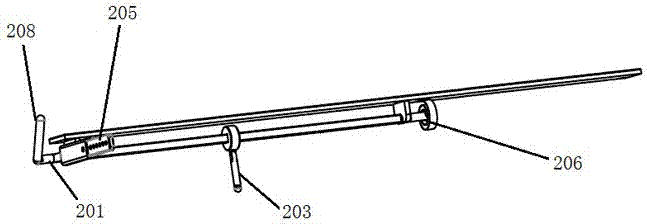

[0027] The shipping mechanism of the present invention includes a shipping platform. The delivery platform includes an inclined delivery channel, and cargo separating and conveying components arranged on the side of the delivery channel. Such as figure 1 , 2 , the cargo separating and conveying part includes a rotating shaft 201 , and a first blocking member 203 , a second blocking member 205 , and an elastic member 206 arranged on the rotating shaft 201 . The cargo separating and conveying parts are arranged in the groove 207 in the shell 202 of the cargo lane partition. Wherein, the rotating shaft 201 runs through the groove 207 along the direction of the delivery channel, and protrudes out of the casing 202, and one end of the rotating shaft extending out of the casing 202 is a free end, and one end disposed in the groove 207 is a fixed end. The first blocking member 203 and the second blocking member 205 are sequentially arranged on the rotating shaft 201 along the deli...

Embodiment 2

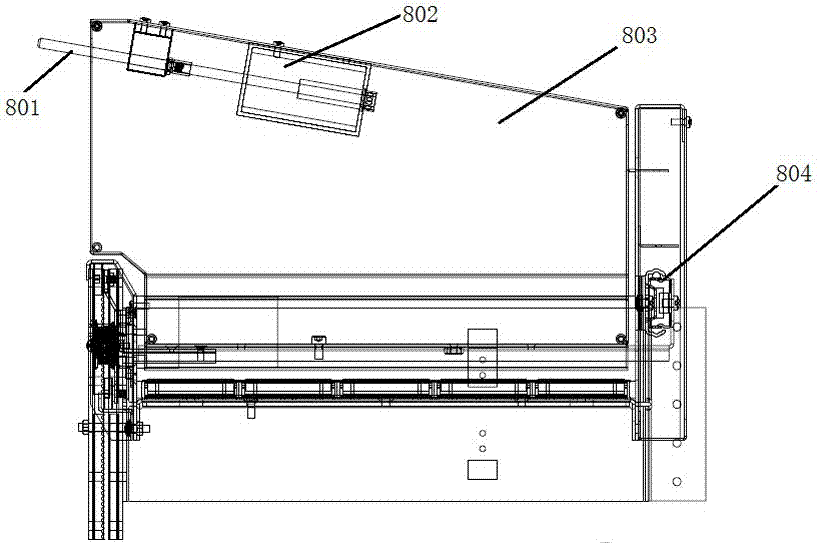

[0032] The delivery mechanism of the present invention also has a toggle component, which provides a toggle force for the goods separating and conveying components in the embodiment, so as to realize automatic delivery. Such as image 3 , the toggle component includes a delivery lever 801 and an electromagnet 802 acting on the delivery lever 801 . Under normal conditions, the electromagnet 802 is not energized; when it is working, the electromagnet 802 is energized, so that the delivery lever 801 stretches out to separate the conveying parts of the goods, making its rotating shaft rotate, and then drives the two blocking parts to switch the working state, realizing sequential delivery. When the goods are finished, the electromagnet is powered off, and a spring can be set in order to reset the delivery lever. The toggle part can also be set as a cylinder. When the cylinder is in action, the cylinder shaft extends to separate the conveying parts for the goods, and the cylinder ...

Embodiment 3

[0035] A delivery system of the present invention includes the delivery mechanism of the first or second embodiment above, and a transmission mechanism. Whether it is the automatic retail industry, or the logistics industry, or other shipping and transmission fields, there are multiple channels for shipment, and each cargo separation and conveying part of each channel can be equipped with a toggle part, but this is costly and complicated. . In order to improve efficiency, several shipping channels can be planned in the form of a toggle component to optimize shipping. For this reason, a transmission mechanism is set, which is used to transmit the toggle component to a specific delivery channel opening for work. The conveying mechanism can be configured as a transverse conveying mechanism or a longitudinal conveying mechanism or a combination of both. The transfer mechanism also includes a loading structure, such as a tray.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com