Liquid fertilizer having active enzyme and full nutrients of seaweed and preparation method thereof

A liquid fertilizer and active enzyme technology, applied in organic fertilizers, liquid fertilizers, fertilizer mixtures, etc., can solve the problems of damaging the active components of seaweed and reducing fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

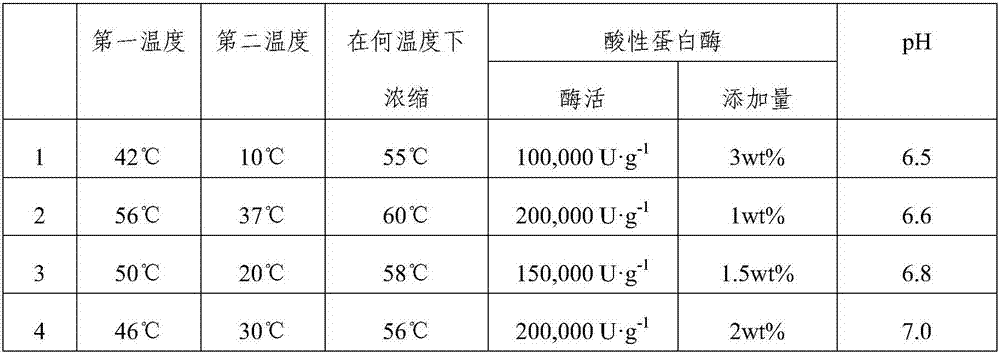

[0036] First, the present invention provides a kind of preparation method of the liquid fertilizer that has active enzyme, seaweed full price nutrition, comprises the steps:

[0037] (1) Utilizing a compound enzyme to enzymatically hydrolyze seaweed at a first temperature to obtain a seaweed enzymolysis solution;

[0038] (2) Filtrate the seaweed enzymolysis solution at a second temperature to obtain a seaweed clear liquid; wherein, the second temperature is lower than the first temperature, and the complex enzyme cannot carry out enzymatic reactions;

[0039] (3) Concentrating the seaweed supernatant to obtain a concentrated supernatant; and

[0040] (4) adding acid protease to the concentrated supernatant, and then adjusting the pH of the concentrated supernatant to 6.5-7.0 to prepare the liquid fertilizer.

[0041] First of all, the present invention inhibits the activity of the enzyme remaining in the enzymolysis solution through low temperature treatment. At the second ...

Embodiment 1

[0071] S11:

[0072] Soak the collected seaweed in clear water to remove impurities in the seaweed and reduce its salt content, then fish out the seaweed and crush it, add water 4 times the quality of the seaweed to the crushed seaweed, and mix well to obtain Seaweed slurry for enzymatic hydrolysis.

[0073] Add the composite enzyme (in composite enzyme, the enzyme activity ratio of cellulase, pectinase, protease and amylase that is made up of cellulase, pectinase, protease and amylase to be 6:1.5 in described seaweed pulp :1:0.8), after mixing evenly, carry out enzymatic hydrolysis at 42°C, after compound enzyme enzymatic hydrolysis, the seaweed slurry becomes a mixed liquid mixed with seaweed enzymatic hydrolysis products and compound enzymes, which is the seaweed enzymatic hydrolysis solution.

[0074] The enzymatic hydrolysis process is a conventional process in the art, and will not be described in detail here.

[0075] S12:

[0076] At 10° C., the seaweed enzymolysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com