A magnetic levitation motor without thrust disc

A magnetic levitation, no thrust technology, applied in the direction of holding devices and electrical components using magnetic attraction or thrust, can solve the problems of limiting the critical speed of the motor, large volume and mass, low motor efficiency, etc., to improve the anti-interference ability and improve the rotor. Speed, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

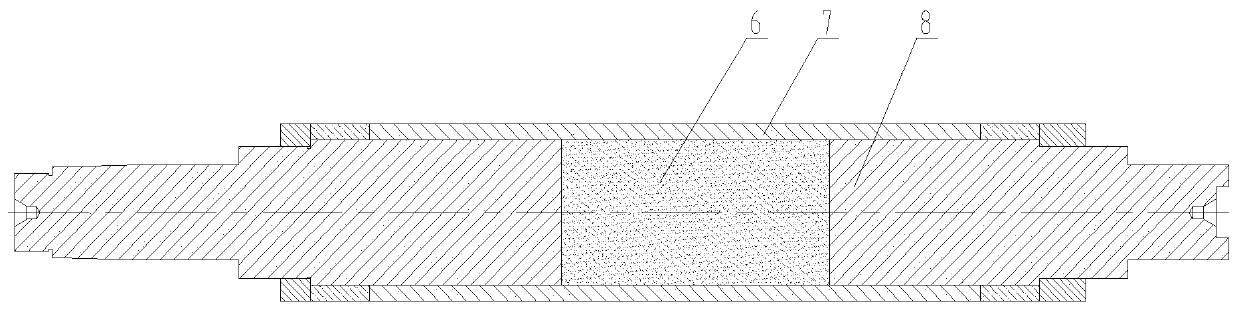

[0022] Such as figure 1 As shown, a magnetic levitation motor without a thrust disk in the present invention is composed of a static part and a rotating part. The static part includes: the static part of the three-degree-of-freedom integrated hybrid magnetic bearing 1, the radial displacement sensor 2, and the high-speed motor 3. The static part, the inner cylinder 4, the housing 5 and the mounting ring 9; the rotating part includes: the rotating part of the three-degree-of-freedom integrated hybrid magnetic bearing 1, the alloy steel rotor 8, the rotor permanent magnet 6 of the high-speed motor 3, and the permanent magnet protective cover 7 and locking threaded ring 10. The high-speed motor 3 is located in the middle of the device, and its rotor permanent magnet is installed in the middle of the two alloy steel rotors 8 by the permanent magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com