Composite blade section property calculation method

A blade profile and characteristic calculation technology, applied in the direction of calculation, design optimization/simulation, special data processing applications, etc., can solve the problems of inaccurate calculation of torsional stiffness, long cycle, heavy workload, etc., to save scientific research cycle and efficiency Improve and accurately calculate the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

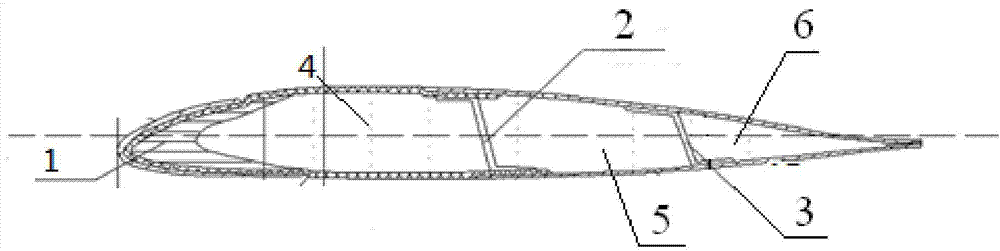

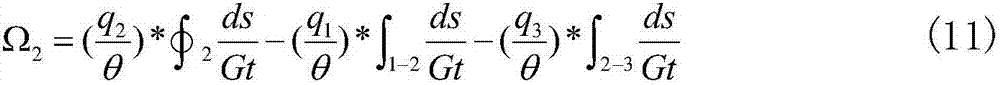

[0041] The section characteristics of the H425 main blade are calculated. The blade includes a C-beam 1 at the front, a Z-beam 2 in the middle and a Z-beam 3 in the rear. Between the C-beam and the Z-beam in the middle Between the Z-beams in the middle and the rear Z-beams, the wall chamber 5 is formed, and the Z-beams at the rear and the end form the wall chamber 6. The calculation results are given and compared with The experimental data were compared.

[0042] 1) Prepare the blade data file;

[0043] 2) Calculate according to the calculation formula of section characteristics:

[0044] Linear density:

[0045] Centroid Offset:

[0046] Tension Center Offset:

[0047] Tensile stiffness: EA=∫∫ A E·dA (4)

[0048] Swing stiffness: EI y =∫∫ A E·(Z-Z T ) 2 dA (5)

[0049] Shimmy stiffness: EI z =∫∫ A E·(Y-Y T ) 2 dA (6)

[0050] Swing coupling stiffness: EI yz =∫∫ A E·(Y-Y T )·(Z-Z T )dA (7)

[0051] Swing inertia: PI y =∫∫ A ρ·(Z-Z T ) 2 dA (8)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com