Flattening tooling platform for products

A tooling and platform technology, applied in the direction of presses, manufacturing tools, material forming presses, etc., can solve the problems of unable to meet the assembly requirements, unable to process plastic products, unable to process, etc., to achieve simple structure, low manufacturing cost, high pressure Flat and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

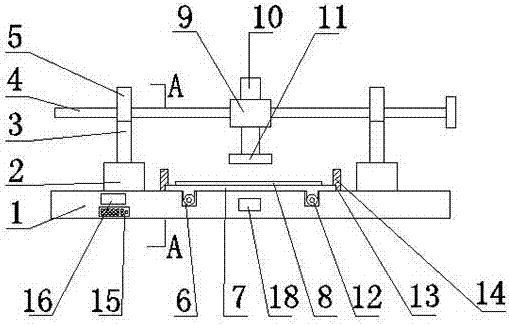

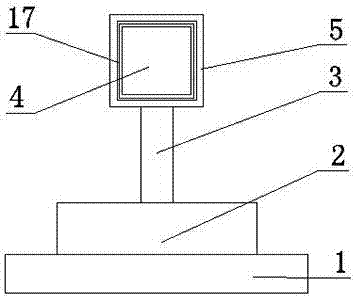

[0018] like figure 1 and figure 2 As shown, a product flattening tooling platform includes a base 1, a support 2, a support rod 3, a push rod 4, a clamping device 5, a flattener and a tooling platform, and the support rod 3 is installed on the base through the support 2 1, one end of the support rod 3 is fixedly installed on the support 2, and the other end is equipped with a clamping device 5, the clamping device 5 clamps the push rod 4, and the middle position of the push rod 4 is fixedly installed with a flattener, A sleeve 17 is set in the through hole of the clamping device 5, and the push rod 4 is installed in the sleeve 17; The lower end of the shaft 10; the tooling platform includes a base 1, a tooling mobile seat 7, a working plate 8 and a baffle plate 14, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com