Full-automatic copper nail implantation machine with adjustable angle

An adjustable, fully automatic technology, applied in the field of auxiliary tooling, to reduce equipment costs, run smoothly, and ensure the quality of nail implants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

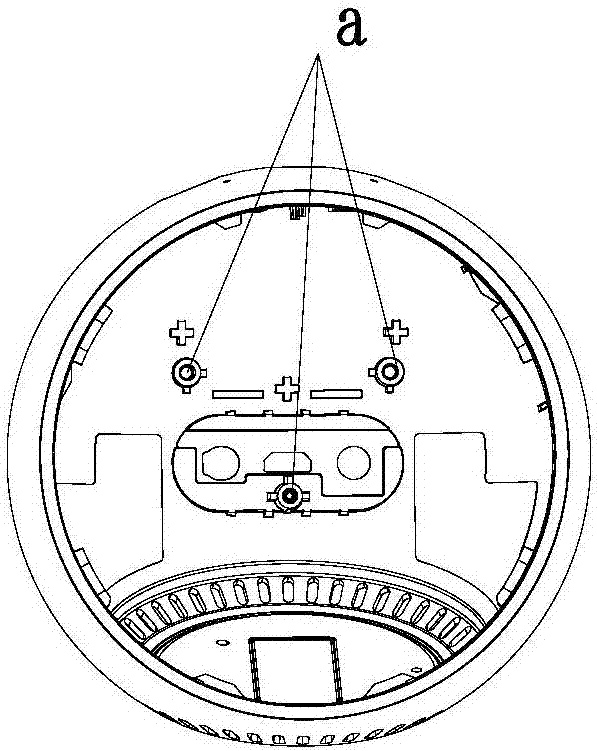

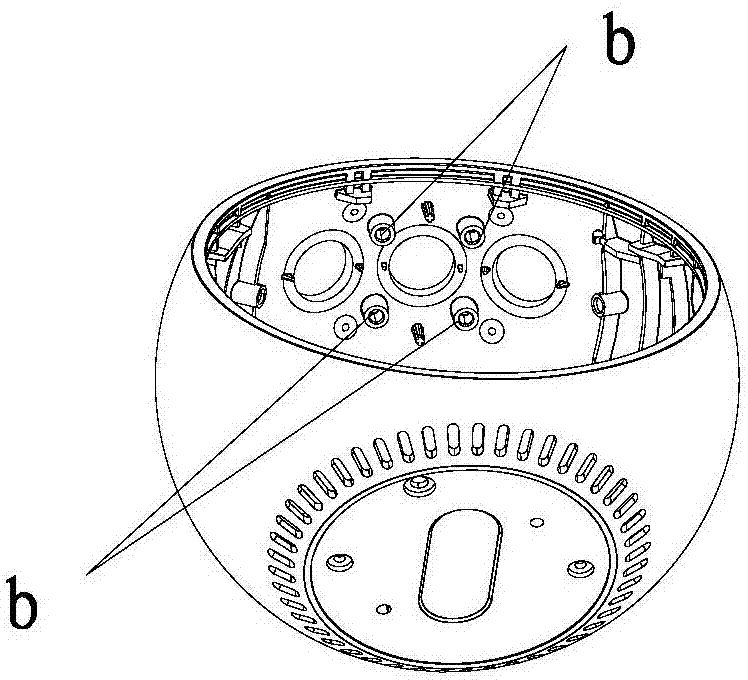

[0022] figure 1 and 2 What is shown in is a spherical plastic part. There are three Y-axis plastic studs a inside the sphere (these three plastic studs a are located on the plane), and four Z-axis plastic studs b, but The four plastic studs b are located on the curved surface, so the positions need to be adjusted when the screws are planted.

Embodiment 2

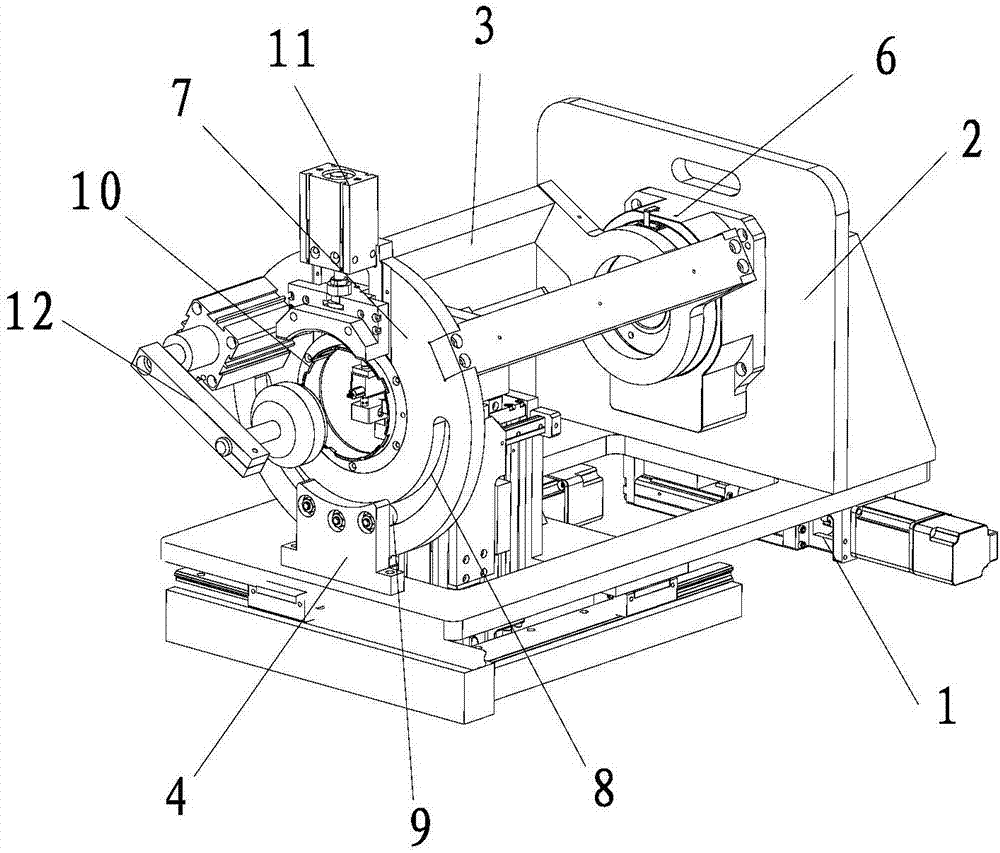

[0024] Angle-adjustable automatic copper nail implantation machine, including vibrating plate and nail embedding module. see image 3 , The nail embedding module is composed of an X-axis rotary positioning module and a YZ-axis automatic nail-melting module, and the vibrating plate supplies nails to the YZ-axis automatic nail-melting module. The X-axis rotary positioning module includes an X-axis linear guide rail 1, a rotary seat 2, a rotary arm 3, a fixture and a cam seat 4, the rotary seat is vertically installed on the X-axis linear guide rail through a base plate 5, and the rotary arm passes through a rotary table 6 is fixed on one side of the rotating seat; the front end of the rotating arm has a disc 7, and the disc surface has an arc groove 8, and the clamp is installed in the center of the disc; the cam seat 4 is fixed on the base plate, and the cam seat The top of the top is provided with two cams 9 that are stuck in the arc groove.

[0025] Fixtures include positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com