A cement roller press equipped with a new feeding device

A technology of feeding device and cement roller, applied in the field of cement roller press, can solve the problems of side leakage of materials, poor sealing, unfavorable production efficiency, etc., and achieve the effect of high-efficiency rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to clearly illustrate the technical features of the present solution, the present invention will be described in detail below through specific implementation methods and in conjunction with the accompanying drawings. It should be noted that components illustrated in the figures are not necessarily drawn to scale. Descriptions of well-known components and techniques are omitted herein to avoid unnecessarily limiting the present invention.

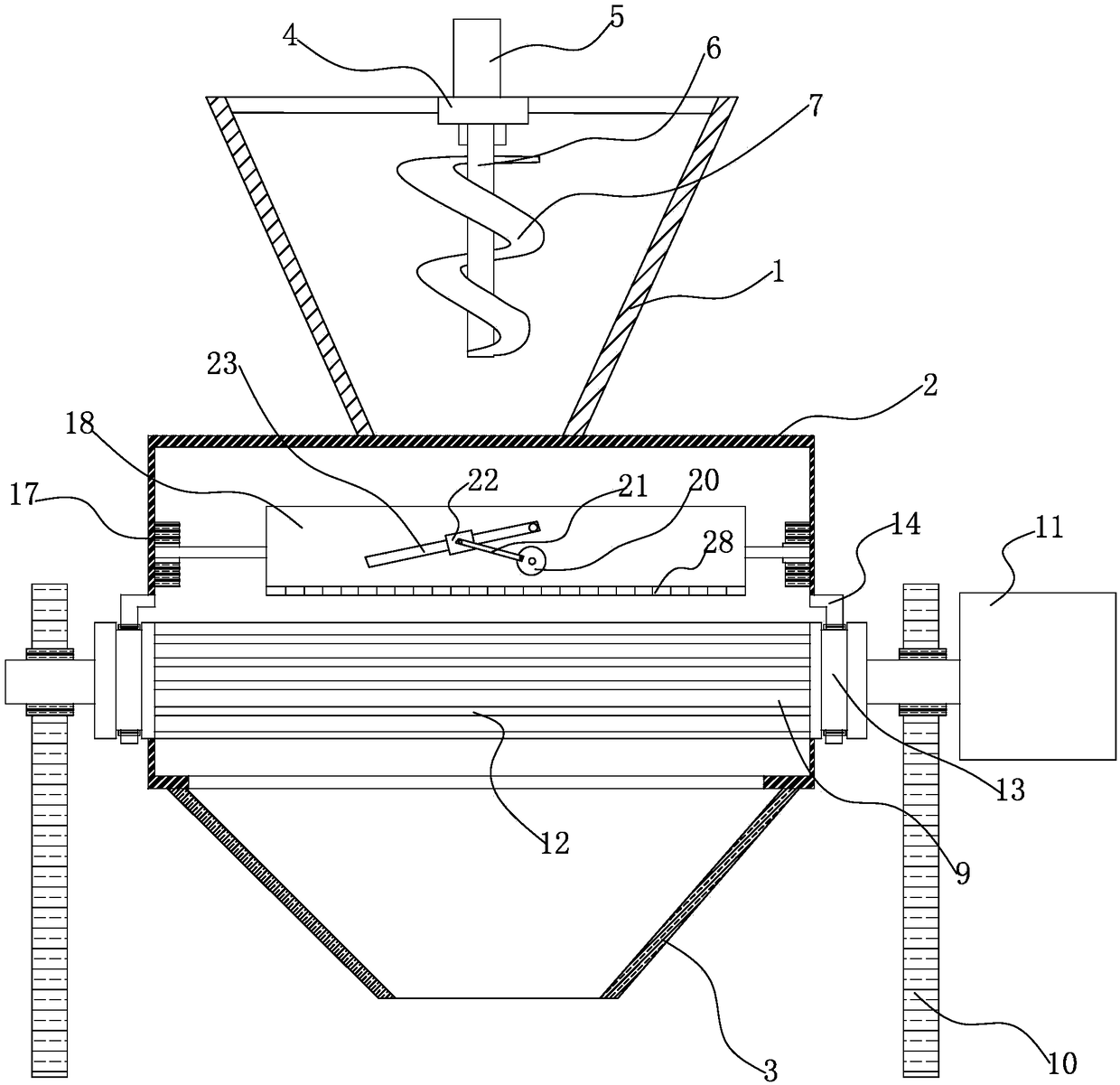

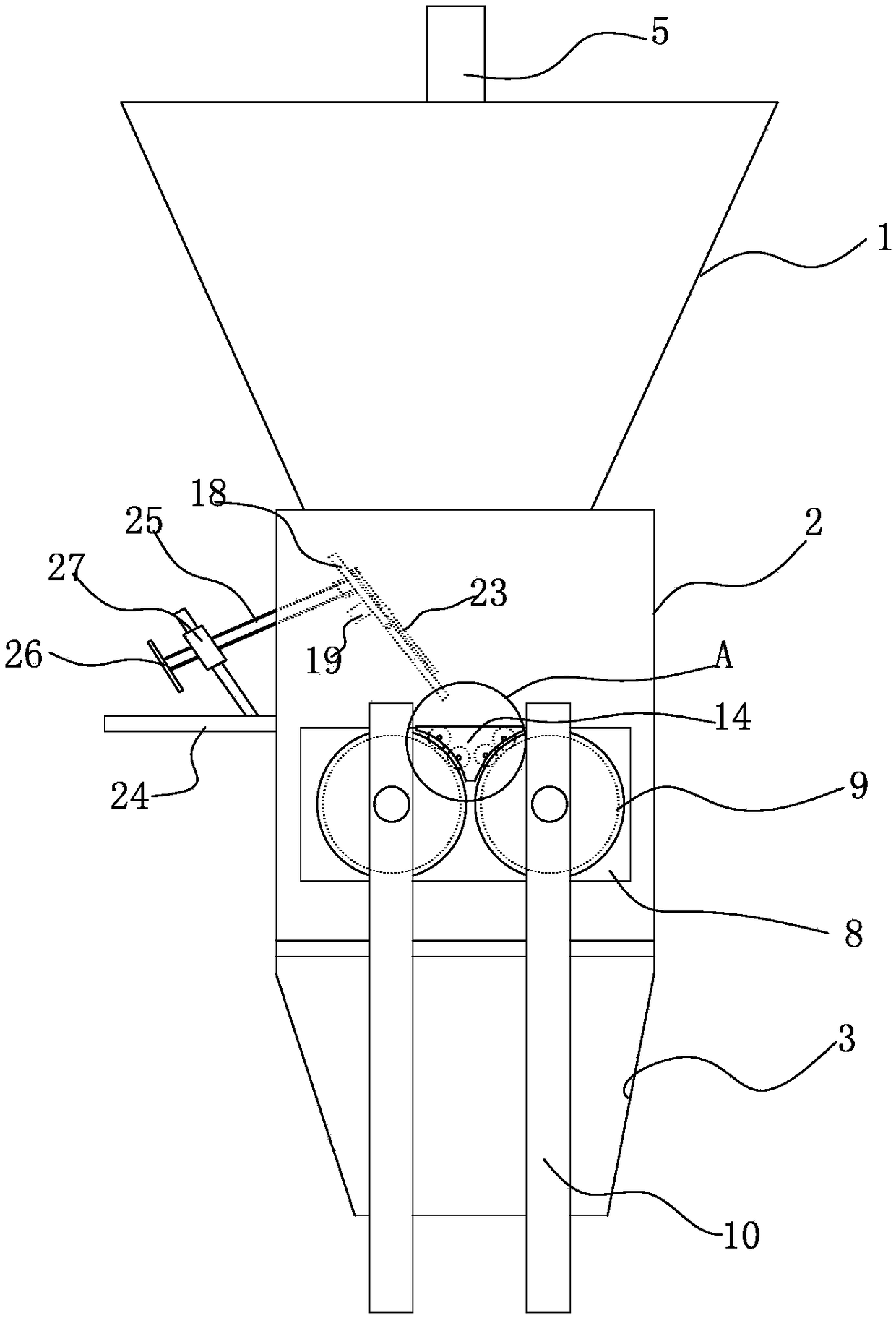

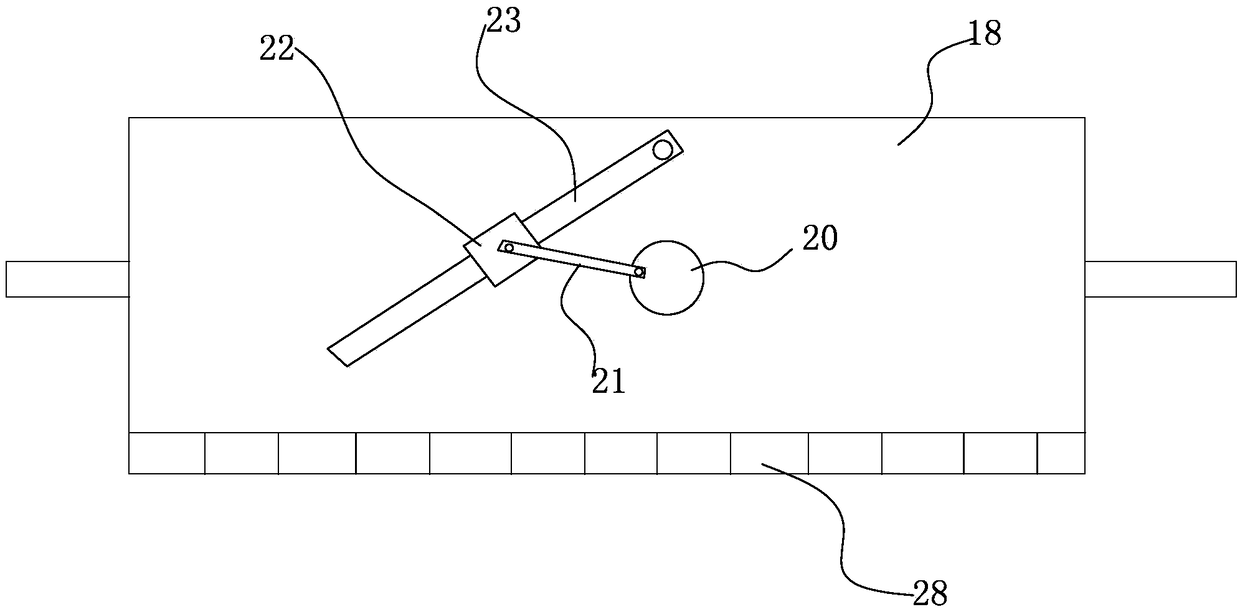

[0023] Such as Figure 1 to Figure 4 As shown, a cement roller press equipped with a new type of feeding device includes a machine case, a screw propulsion mechanism, a roller pressing wheel mechanism, a material equalizing mechanism and a side leakage prevention plate mechanism. The chassis mainly plays the role of installation and fixing, and the chassis includes an upper feeding port 1, a middle rolling cavity 2 and a bottom discharging port 3.

[0024] The upper feed port 1 adopts a V-shaped mechanism to facilitate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com