Medium conveying device and medium conveying system

A medium conveying and medium technology, applied in coin accepting devices, instruments, handling coins or valuable banknotes, etc., can solve problems such as low strength of paper materials, failure of conveying structure, tearing, etc., to improve reliability and operation performance, avoid clogging, and protect integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

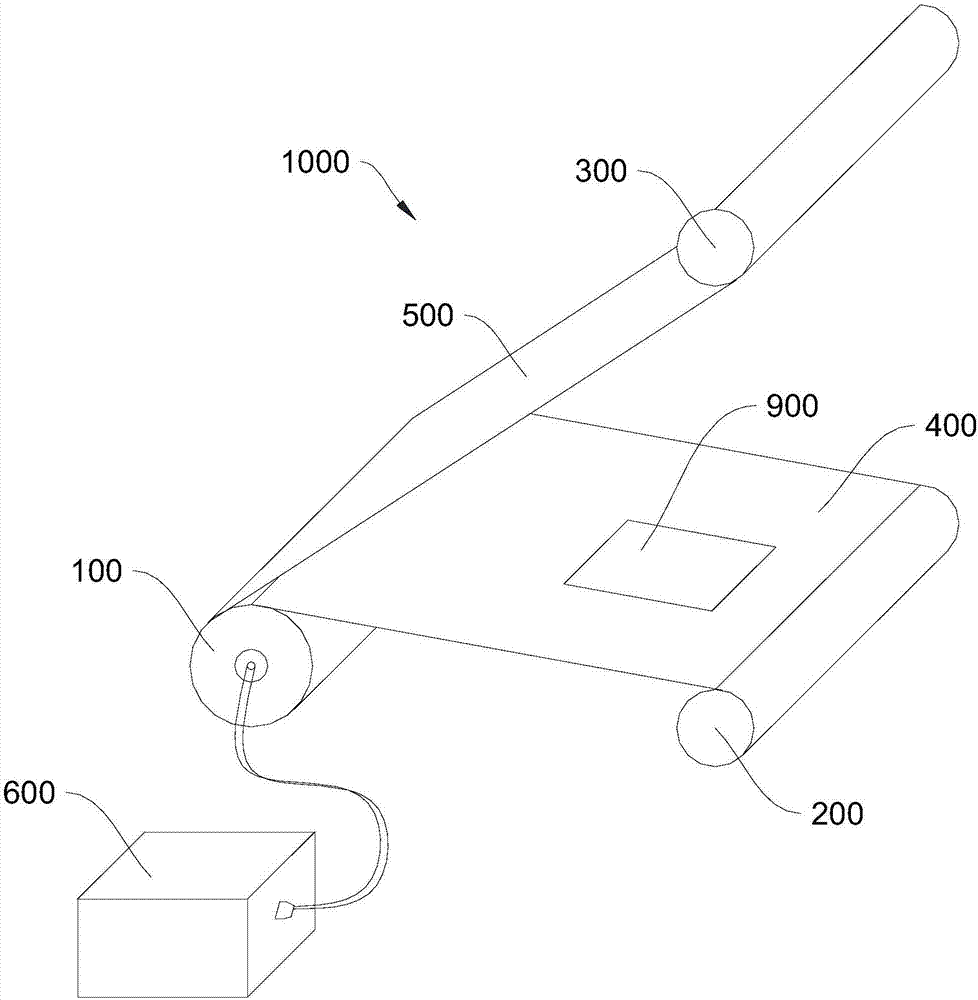

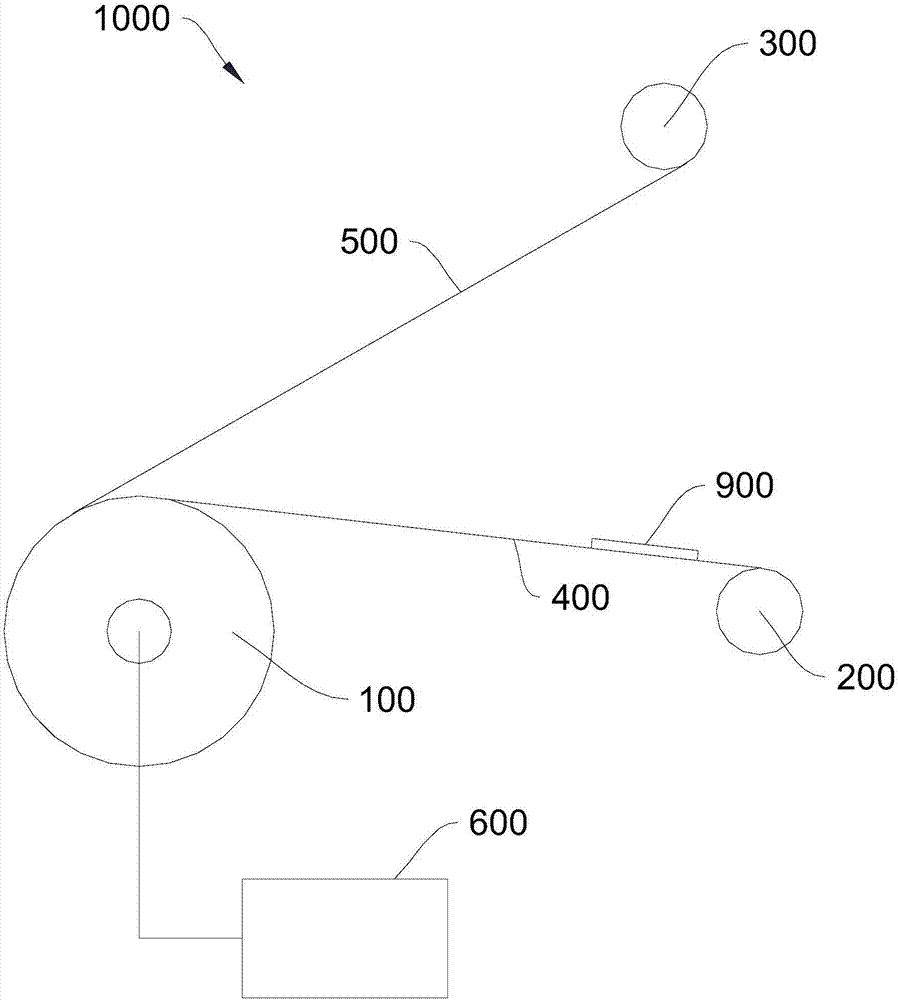

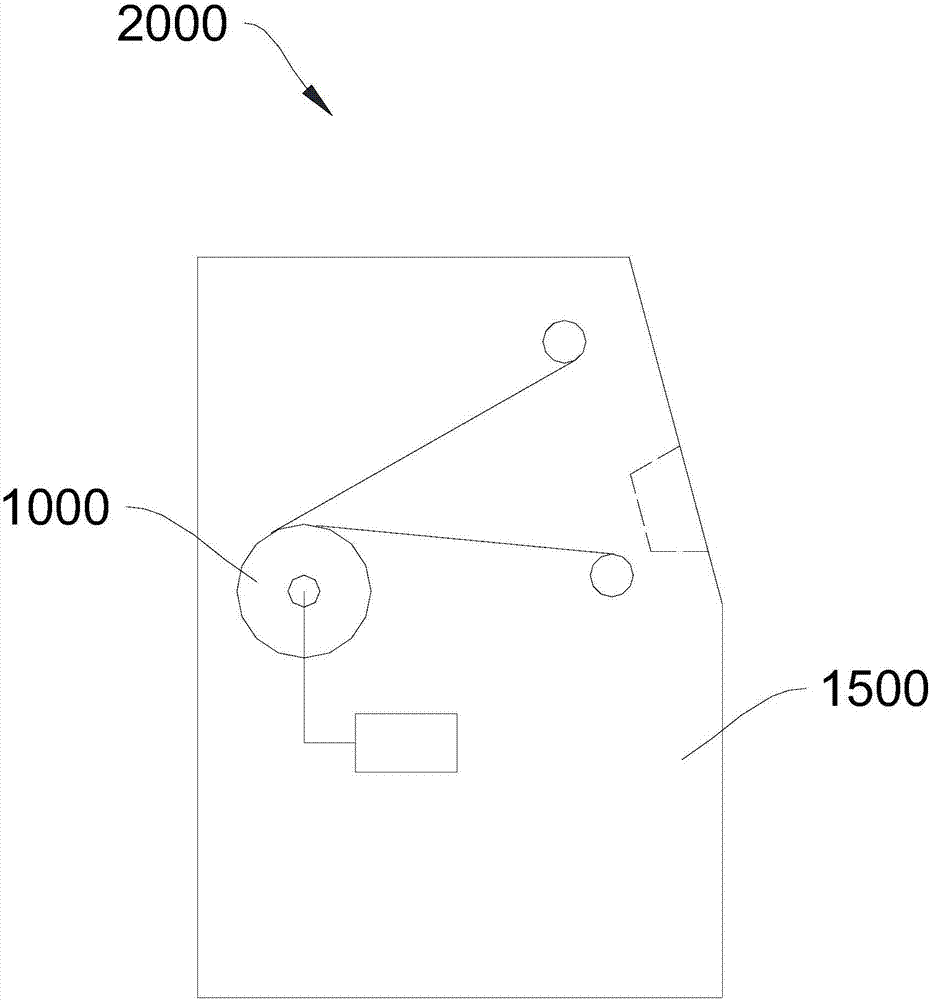

[0039] Please refer to figure 1 ,, this embodiment provides a medium conveying device 1000 , which includes a reel 100 , a first drum 200 , a second drum 300 , a first conveyor belt 400 , a second conveyor belt 500 and a driving motor 600 . Both ends of the first conveyor belt 400 are respectively wound on the reel 100 and the first drum 200 , and both ends of the second conveyor belt 500 are respectively wound on the reel 100 and the second drum 200 . The rotating drum 300, the reel 100 is electrically connected with the driving motor 600, and the driving motor 600 is used to drive the reel 100 to rotate clockwise or counterclockwise and drive the first conveyor belt 400 and the The second conveyor belt 500 moves along with the reel 100 . Wherein, the width of the first conveyor belt 400 is greater than the width of the preset medium 900 .

[0040] In this embodiment, the preset medium 900 may be banknotes, coins and other cash. It can be understood that the preset medium ...

no. 2 example

[0056] Please refer to Figure 4 , this embodiment provides a medium conveying device 1000, the biggest difference from the first embodiment above is that, in this embodiment, between the first conveying belt 400 and the second conveying belt 500 close to the first A conveying belt 400 is provided with a medium stretching part, and there is a gap between the medium stretching part and the first conveying belt 400 , and the rotation direction of the medium stretching part is opposite to that of the reel 100 .

[0057] In this embodiment, the medium stretching part includes a first conveying roller 710 and a second conveying roller 720 arranged in sequence along the direction close to the rotating shaft, and the first conveying roller 710 and the second conveying roller 720 are driven The first conveying roller 710 and the second conveying roller 720 rotate in the same direction, and the position of the first conveying roller 710 is higher than that of the second conveying rolle...

no. 3 example

[0061] Please refer to Figure 6 , this embodiment provides a medium conveying device 1000, the biggest difference from the first embodiment above is that in this embodiment, the second conveying belt 500 wound on the reel 100 is far away from the reel 100 One side of the second conveyor belt 500 is also provided with a rear end holding part 800, and the rear end holding part 800 is against the side of the second conveyor belt 500 away from the reel 100, and the movement of the second conveyor belt 500 can drive the The rear end holding part 800 is rotated.

[0062] In this embodiment, preferably, the rear end holding part 800 is connected to the driving motor 600, and the driving motor 600 is used to drive the rear end holding part 800 to rotate in the direction opposite to the rotation direction of the reel 100. . The rear end holding part 800 is driven to rotate by an external force through the driving motor 600, so that the preset medium 900 is under stronger pressure fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com