Combined cooling type rectification support plate flame stabilizer

A technology of flame stabilizer and rectifier support plate, which is applied in the combustion method, combustion chamber, combustion equipment and other directions, can solve the problems of the adverse effect of the working life of the rectifier support plate flame stabilizer, the change of flame stability performance, etc., and achieve combustion stability. , prolong the service life, avoid the effect of coking blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] The present invention will now be further described in conjunction with the drawings:

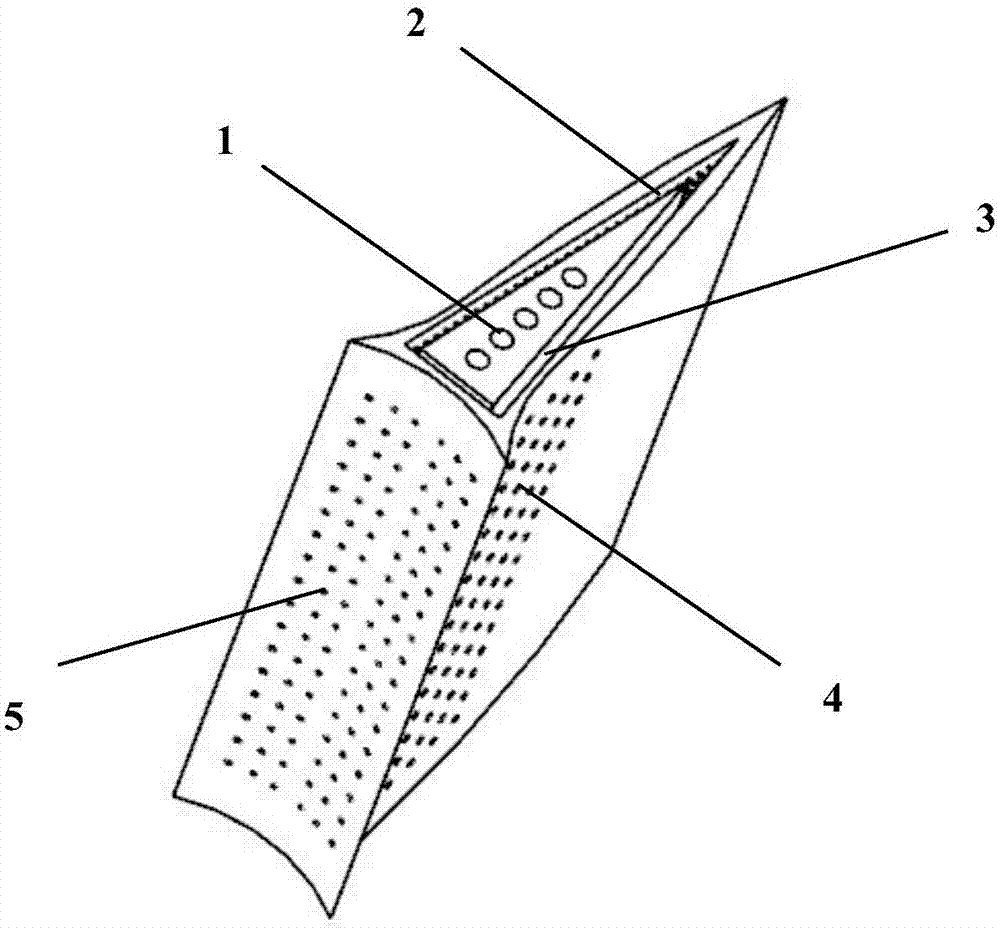

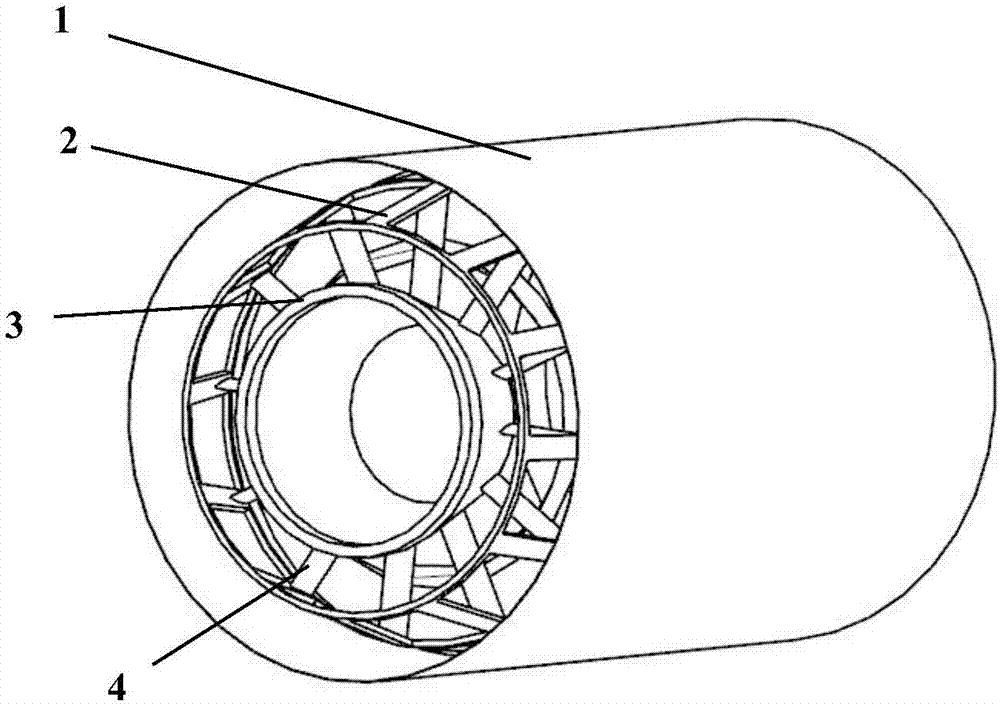

[0021] Combine figure 1 , figure 2 , The present invention provides a new type of flame thermostat that can cool and protect the rectifying support plate under high-temperature gas, and improve its working stability. At the same time, by changing the cooling structure of the film hole, adjusting the pressure difference, and the amount of cold air, the active control of the intensity of the combustion zone and the combustion stability is realized.

[0022] Such as figure 2 The high temperature fuel gas shown in the content enters the integrated afterburner through the outside of the 3-afterburner inner cone. The airflow at the inlet of the afterburner has a high temperature and is turbulent after the turbine blades are disturbed. The high-temperature gas is rectified by the flame stabilizer of the 4-rectification branch plate and then organized and burned behind it. It can be seen tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com