Expressway protective fence based on waste tires and manufacturing method thereof

A technology for waste tires and highways, applied in the field of traffic safety, can solve the problems of inability to ensure safety, collision of guardrails, casualties, etc., and achieve the effect of high practical value, elimination of collision and combustion, and safety protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

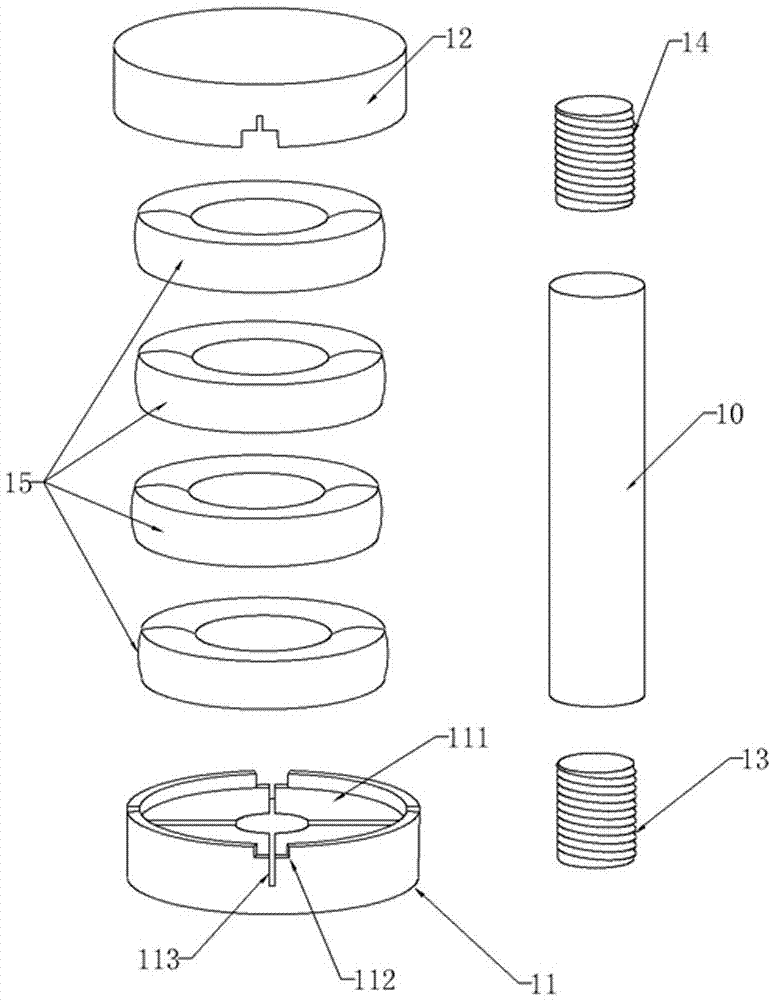

[0030] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

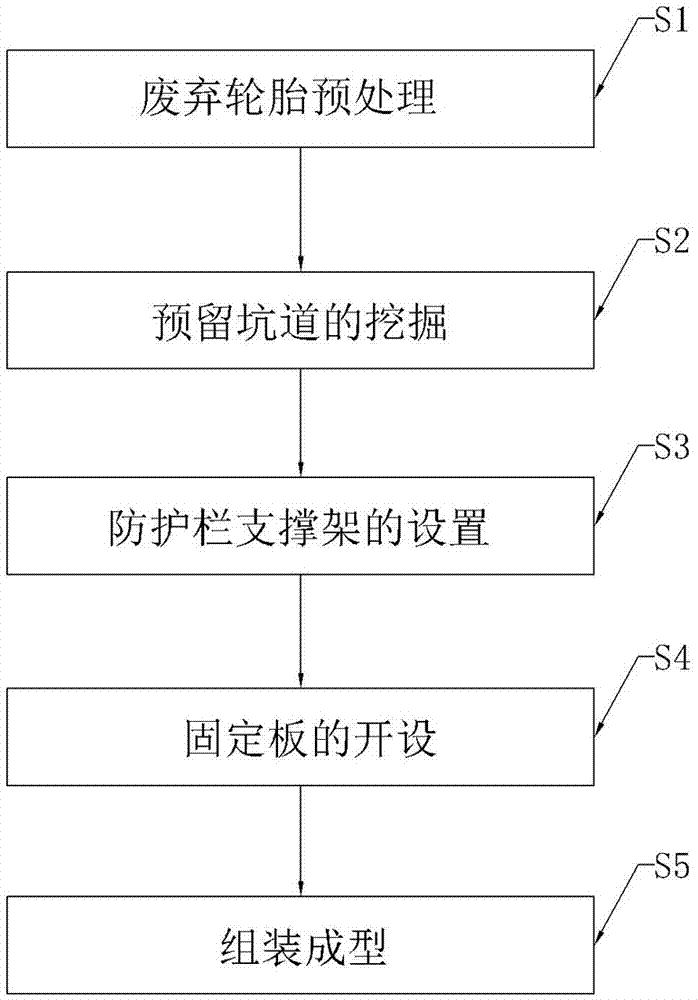

[0031] refer to figure 1 , the present invention is based on a waste tire highway guardrail, including a cement column 10, a fixed base plate 11, a fixed panel 12, a first bolt 13, a second bolt 14 and a plurality of waste tires 15, and the fixed base plate 11 is accommodated on the ground In the reserved tunnel below, the first bolt 13 and the second bolt 14 are respectively fixed on the two ends of the cement column 10, the fixed bottom plate 11 is provided with an internal thread structure compatible with the first bolt 13, and the fixed panel 12 is provided with There is an internal thread structure compatible with the second bolt 14, and a plurality of discarded tires 15 are sequentially sleeved on the cement column 10 in such a way that the outer diameter gradually decreases, and the discarded tires 15 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com