Positive tension compensating device for tricot knitting

A compensation device and active technology, applied in warp knitting, textile and papermaking, knitting and other directions, can solve the problems of tension compensation lag, compensation lag, no active tension compensation device found, etc., to achieve the effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

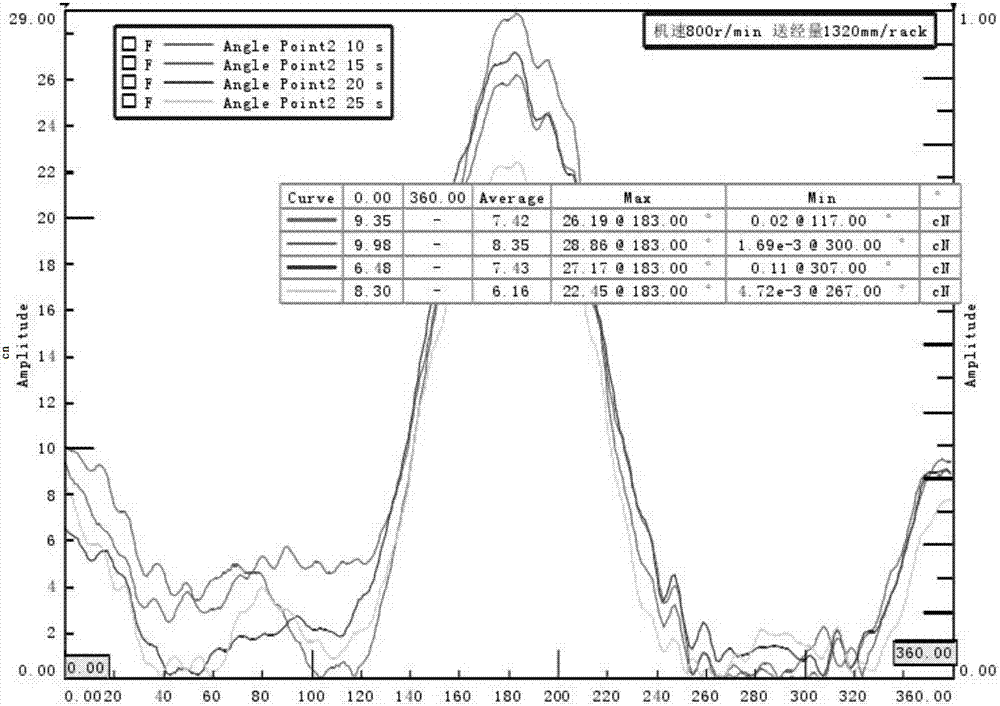

[0034] Such as figure 1 Shown is a typical tension fluctuation curve.

[0035] figure 1 It is on the KS4-EL warp knitting machine, only GB2 is used, 83.3dtec polyester low elastic yarn is fully worn, the lapping weave is 1-0 / 1-2 / / , and the let-off is 1320mm / rack. The tension fluctuation obtained from the test curve.

[0036] from figure 1 It can be seen that the main peak appears in the range of 100°-250° of the main axis, and the maximum, minimum and average value of the tension value can be read.

[0037] The relationship between △θ and △H is: △θ=△H / R, where R is the length of the steel plate;

[0038] The relationship between △a and △i is: △a=k·△i, where k is a constant term.

Embodiment 2

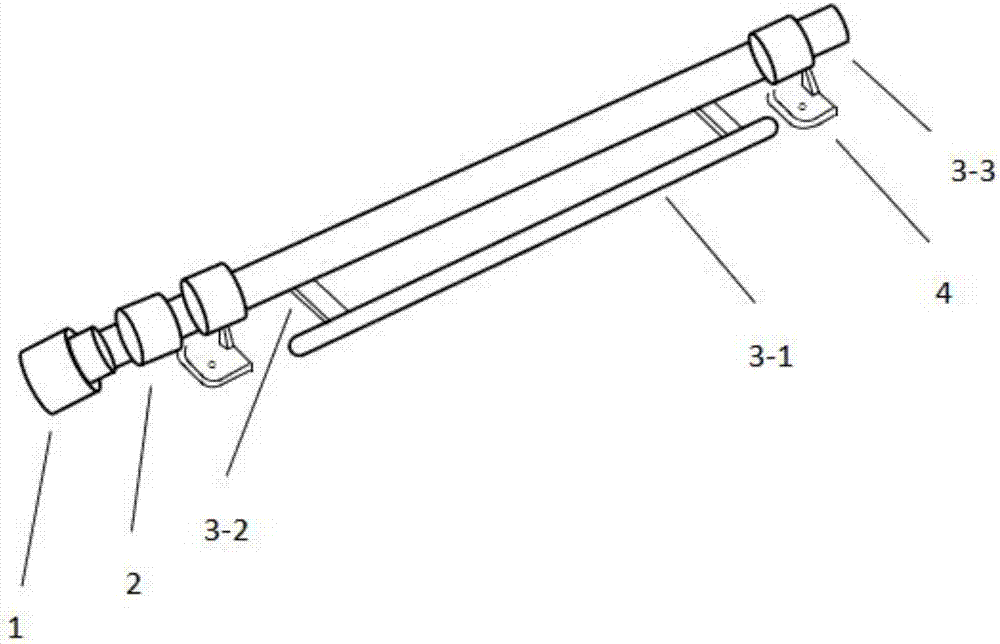

[0040] Such as figure 2 As shown, it is a schematic diagram of functional components of warp knitting positive tension compensation device, including: motor drive device 1, coupling 2, rigid tension rod 3-1, steel plate 3-2, shaft 3-3, bearing seat 4; Described bearing seat 4 can be installed on the frame of warp knitting machine, and described bearing seat 4 is sleeved with shaft 3-3, and one end of described shaft 3-3 is provided with coupling 2, and described shaft coupling 2 The other end is provided with a motor drive device 1, and the coupling 2 is connected to the shaft of the motor drive device 1; the rigid tension rod 3-1 is connected to the shaft 3-3 through a steel plate 3-2.

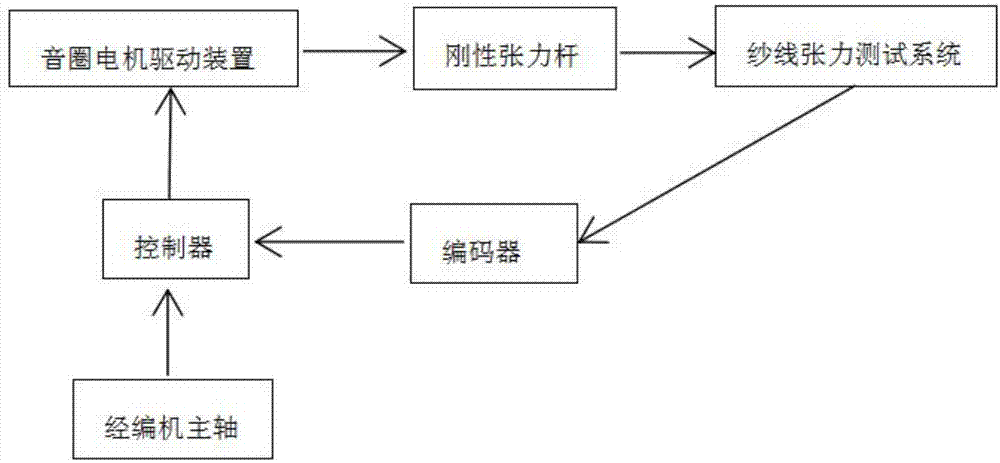

[0041] Such as image 3Shown is the warp-knitted positive compensation device and its working flow chart of the present invention. The warp knitting positive tension compensation device includes a motor drive device 1 and a rigid tension rod 3-1; the motor drive device 1 drives and control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com