Device capable of preventing inertia swing of unmanned overhead crane clamp

A technology of cranes and clamps, which is applied in the field of devices where the clamps swing greatly during the operation of the cranes. It can solve problems such as the inability to achieve precise stacking of steel coils, so as to prevent the swing angle of the clamps, improve work efficiency, and ensure stability. running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

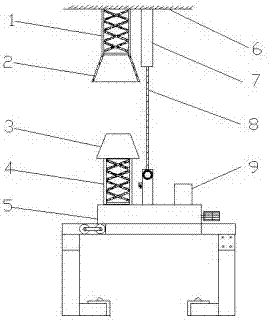

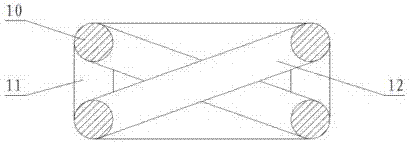

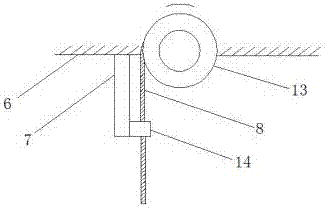

[0019] see Figure 1 ~ Figure 4 , The present invention mainly is made up of trapezoidal cover 2, trapezoidal plug 3, trapezoidal cover connecting beam 1, trapezoidal plug connecting beam 4, steel rope guide beam 7, counterweight 9, guide wheel group 14 etc.

[0020] The figure shows that the trapezoidal cover 2 and the trapezoidal plug 3 are respectively welded on the trapezoidal cover connecting beam 1 and the trapezoidal plug connecting beam 4, and the trapezoidal cover connecting beam 1 and the trapezoidal plug connecting beam 4 are respectively welded on the bottom of the trolley 6 and the The upper part of the clamp 5, the trapezoidal plug 3 and the internal space of the trapezoidal cover 2 just fit, when the clamp 5 of the unmanned crane is lifted to a safe height by the crane hoist 13, the trapezoidal plug 3 is just inserted into the trapezoidal cover 2, so that no The trolley 6 of the overhead crane is integrated with the clamp 5 to avoid the swing of the clamp 5 prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com