System for optimizing commercial vehicle engine vibration performance

A vibration characteristic and engine technology, applied in the direction of power plant, vehicle parts, jet propulsion device, etc., can solve the problems of engine vibration, engine body control strategy adjustment, engine vibration problem not monitored in time, etc., to achieve vibration characteristic optimization and reduction The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

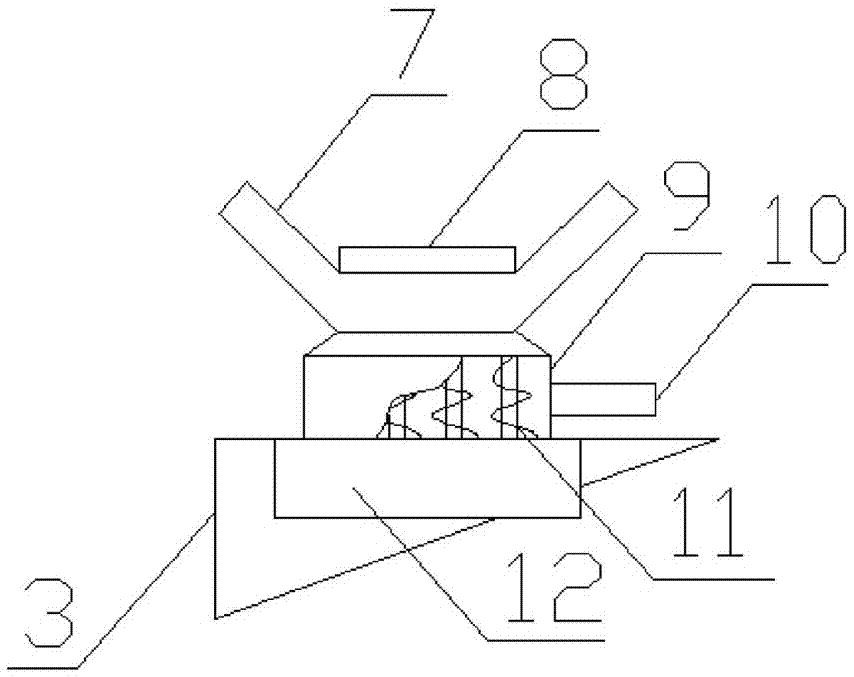

[0017] to combine Figure 1-Figure 4 As shown, the present invention is further described as follows: a system for optimizing the vibration characteristics of a commercial vehicle engine, consisting of a vibration sensor 4, an in-cylinder pressure sensor 6, an alarm, a combination instrument, a single-chip microcomputer, a regulating switch, a suspension cushion 5, Composed of a vacuum pump (not shown in the figure) and a drive motor (not shown in the figure), the vibration sensor 4 is installed at the four suspension cushions 5 at the front and rear of the engine and at the flywheel to monitor the vibration of the entire engine; the suspension cushion 5 It is a suspension cushion with variable thickness, which is installed at the connection between the engine and the frame; the vibration sensor 3 is installed at the four suspension cushions at the front and rear of the engine and at the flywheel to monitor the vibration of the entire engine; the cylinder pressure sensor 6 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com