An automatic unloading machine

A technology of automatic blanking and driving motor, which is applied in the direction of forging/pressing/hammering machinery, forging/pressing/hammer device, manufacturing tools, etc., which can solve the problem of easily damaged workpieces, easily scalded operators, and high labor intensity in the blanking process. and other problems, to achieve the effect of compact structure design, improved processing quality and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

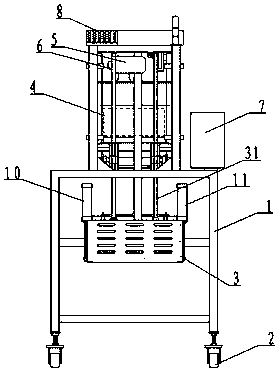

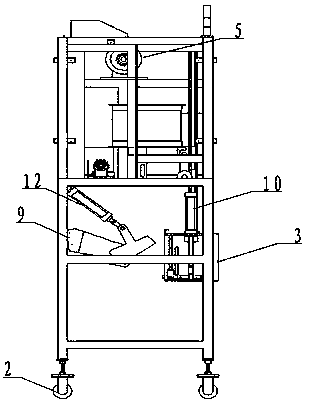

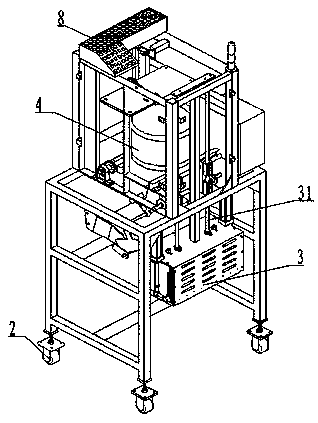

[0019] see Figure 1 to Figure 4 , the embodiment of the present invention includes:

[0020] Described a kind of automatic unloading machine, comprises: bracket, and bracket is divided into upper bracket and lower bracket, wherein four supporting leg structures are arranged on lower bracket, and caster is set at the lower end of supporting leg, makes automatic unloading machine through caster It is convenient to move, an optimal technical solution, a crossbeam is set between the supporting legs of the lower bracket, and the stability of the whole blanking machine is reinforced by the crossbeam.

[0021] A fan is fixedly connected between the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com