Multi-station automatic cycle soup rice making equipment

A technology of automatic circulation and claypot rice, which is applied in mechanical equipment, lighting and heating equipment, transmission devices, etc., can solve problems such as difficulty in uniform quality of meal delivery, inability to make claypot rice, and reduced meal delivery efficiency, so as to reduce waiting Time, improve the efficiency of meal delivery, improve the rate of meal delivery and the effect of accuracy of meal delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to illustrate the technical solution of the present application more clearly, the specific implementation manners of the present application will be described in detail below in conjunction with the accompanying drawings.

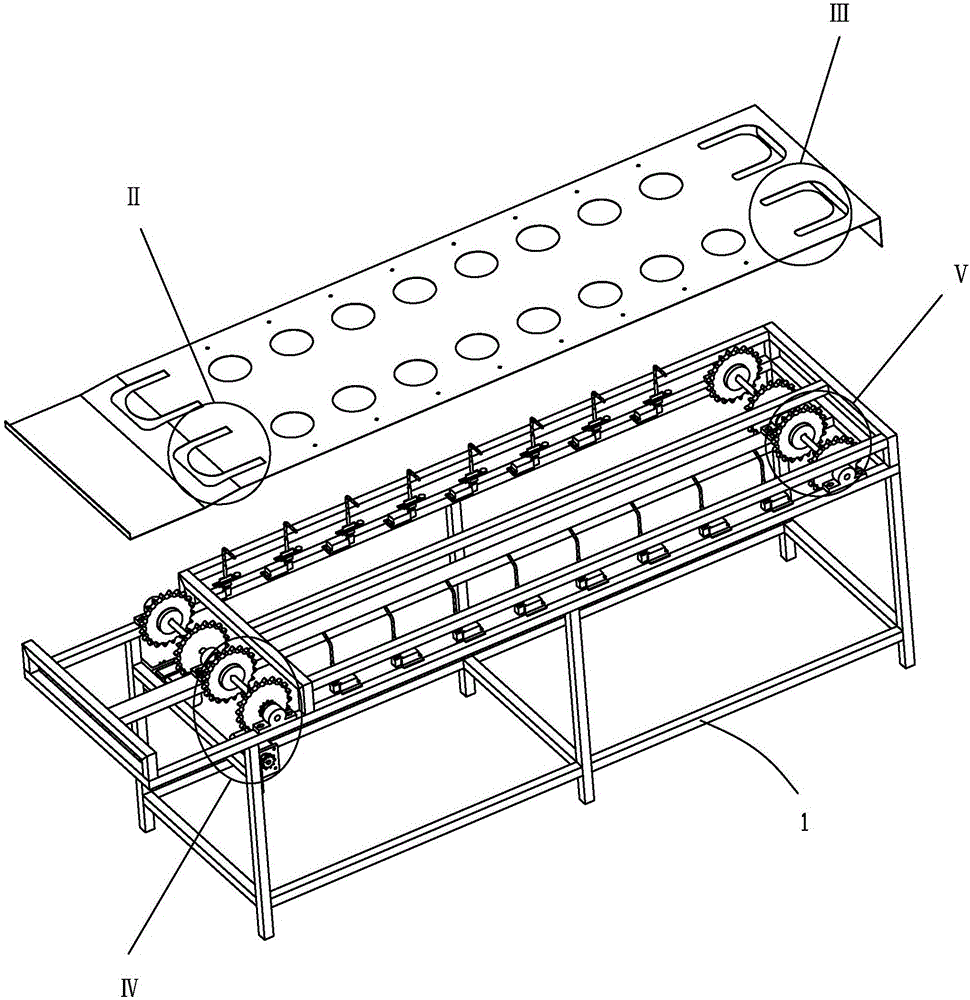

[0049] Such as Figure 1 to Figure 9 It shows the multi-station automatic cycle production claypot rice equipment of the present application, including a frame 1, a production line 2, a heating device 3 and a distribution box.

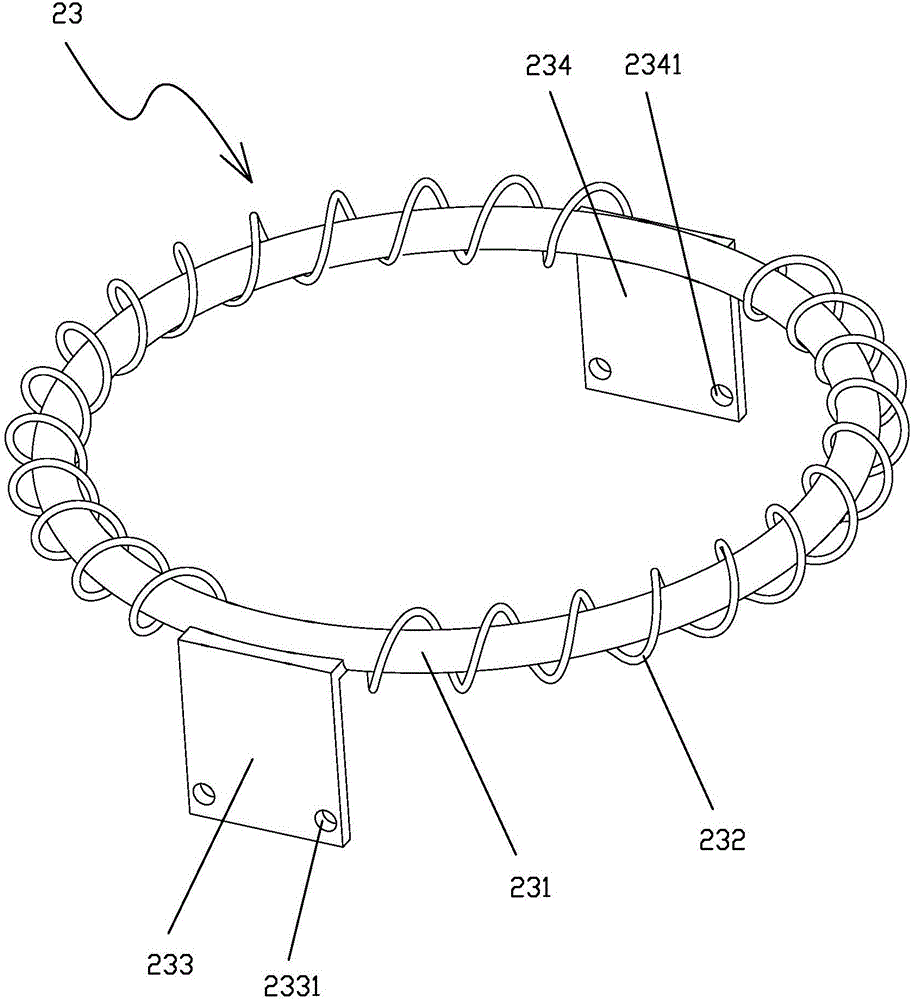

[0050] Specifically, the production line 2 is set on the frame 1 for heating and making claypot rice, and the number is two. The production line 2 includes a driving mechanism 21 , a transmission mechanism 22 , a supporting frame 23 , a heating assembly 24 and a control device 25 . The driving mechanism 21 is located on the left side of the frame 1 . The transmission mechanism 22 is located on the upper side of the driving mechanism 21 , is connected with the driving mechanism 21 , and is driven to rotate by the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com