Gas-liquid substitution and vacuuming personnel protection cabin

A protection cabin and vacuum pumping technology, which is applied in the field of protection cabin, can solve the problems that it cannot be used in a manned space, the life safety of personnel is threatened, and the gas purity is difficult to guarantee, so as to reduce the waste of protection period, simple structure and low consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described below.

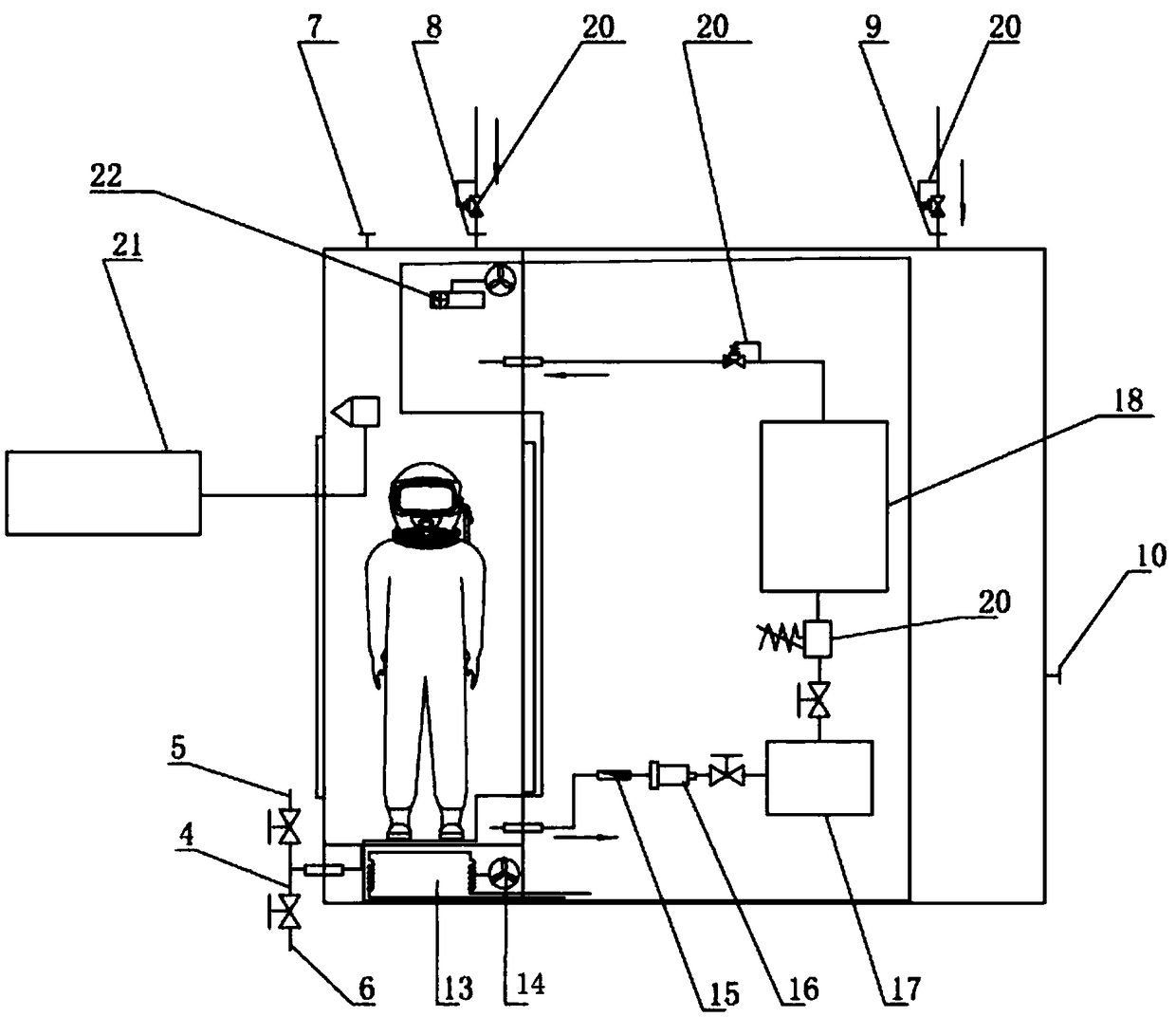

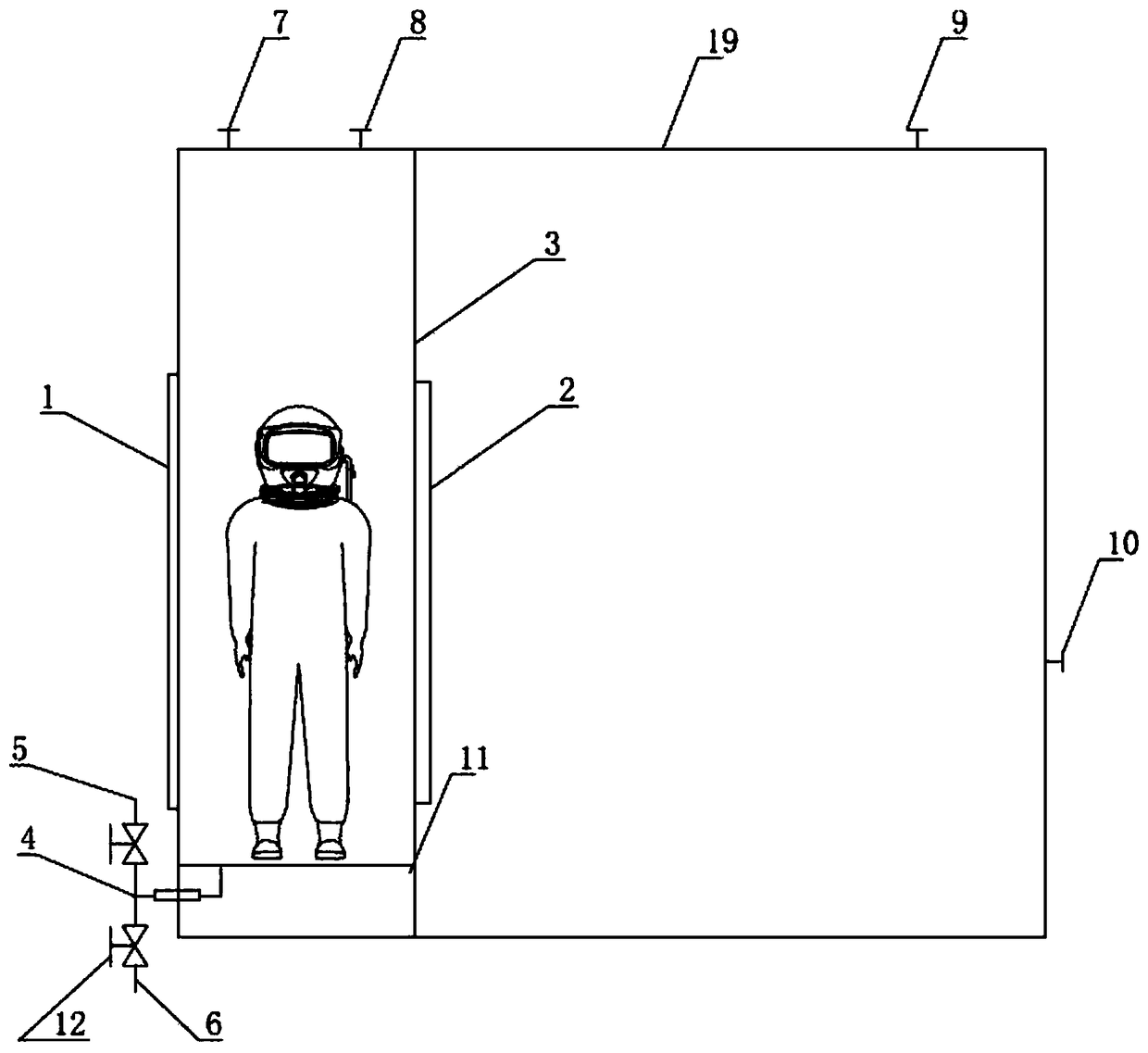

[0020] Such as figure 1 As shown, the gas-liquid substitution and vacuuming personnel protection cabin includes a vacuuming cabin 19, a protective cabin main body 3 is set in the vacuuming cabin 19, and a vacuuming cabin for entering the protective cabin main body 3 is arranged on one side of the vacuuming cabin 19 The airtight door 1 is provided with a protective cabin airtight door 2 on one side of the protective cabin main body 3; the air exhaust port 7 and the first filling protective air port 8 are arranged on the top of the protective cabin main body 3, and are respectively set on the vacuum chamber 19 The second filling and protection gas port 9 and the vacuum chamber pumping port 10; also include the injection and discharge pipeline tee 4, the first end of the injection and discharge pipeline tee 4 is connected to the liquid injection port 4, and the injection and discharge pipeline tee 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com