Oil level detection method, oil level detection device and range hood

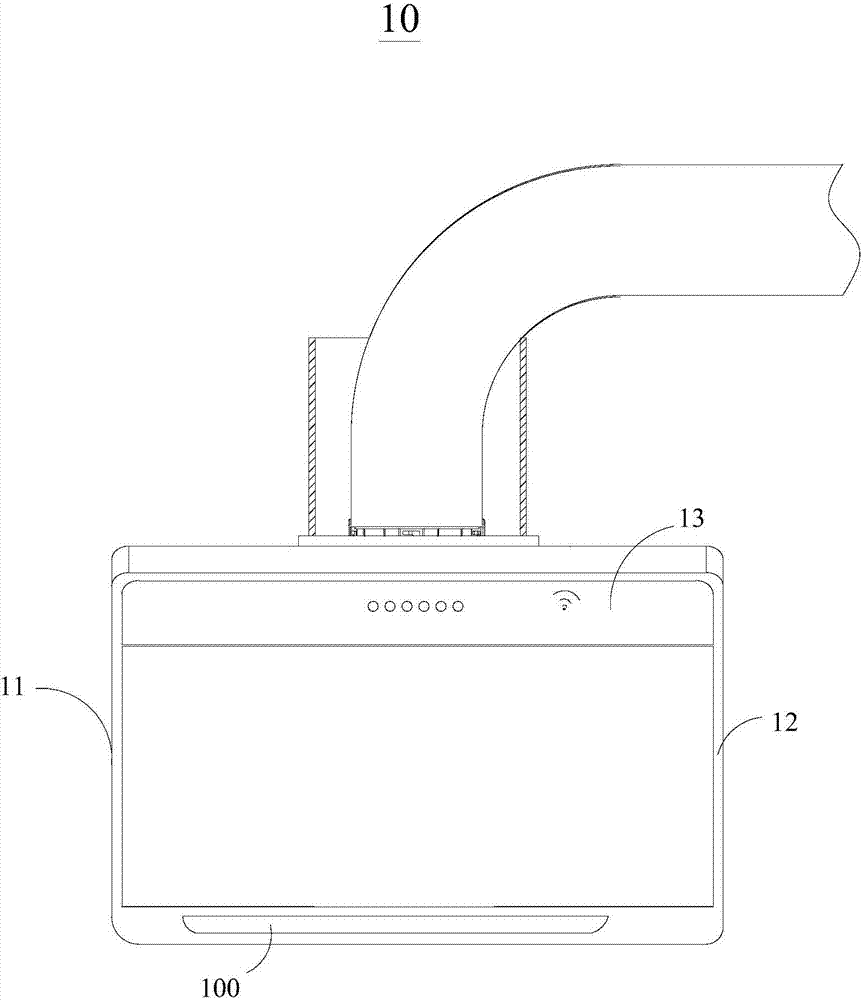

A technology of oil level detection and range hood, which is applied in the direction of oil fume removal, heating method, household heating, etc. It can solve the problems of easy contamination of the detection device and inaccurate oil level detection, and achieve the effect of convenient installation and beautiful structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0027] Please refer to figure 2 , is a structural block diagram of the oil level detection device 200 provided in the first embodiment of the present invention. The oil level detection device 200 includes a controller 201 , a distance sensor 202 , a memory 203 , a communication module 204 and an alarm 205 . The distance sensor 202, memory 203, communication module 204 and alarm 205 are all electrically connected to the controller 201, the housing includes a cavity, the controller 201, memory 203, communication module 204 and alarm 205 is disposed in the cavity.

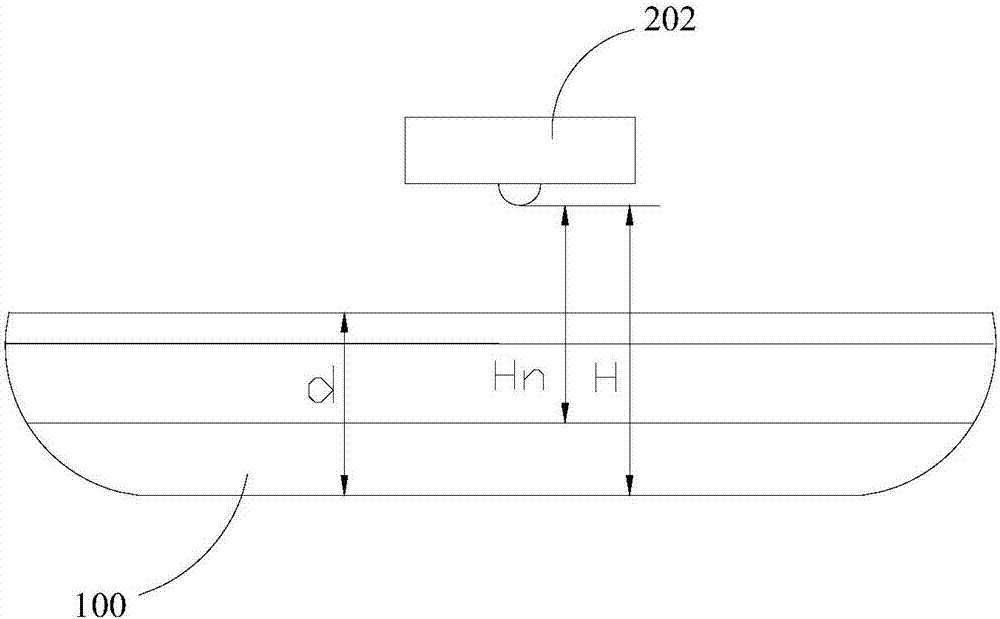

[0028] The distance sensor 202 is used to detect the distance from the oil surface in the oil cup 100 . Specifically, the distance measurement may be performed at a preset time, for example, the controller 201 controls the distance sensor 202 to perform distance measurement every 30 minutes from the range hood 10 . The distance sensor 202 also sends the measured distance to the controller 201 .

[0029] The contr...

no. 2 example

[0040] Please refer to Figure 4 and combine figure 1 , Figure 4 It is a partial structural schematic diagram of the range hood 10 provided by the second embodiment of the present invention. The difference between this embodiment and the first embodiment is that the distance sensor 202 of this embodiment can be arranged on the side wall of the range hood 10, and the distance sensor 202 can be an infrared range finder or a laser range finder.

[0041] The distance sensor 202 and the mirror 206 are respectively disposed on the first side wall 11 and the second side wall 12 . The distance sensor 202 can measure the distance between the probe of the distance sensor 202 and the bottom of the oil cup 100 when the range hood 10 is used for the first time and the oil cup 100 is empty, as the initial distance. When the range hood 10 is in use, each time the distance sensor 202 measures, the detected distance between the probe of the distance sensor 202 and the oil surface in the oi...

no. 3 example

[0045] Please refer to Figure 5 , is a flow chart of the oil level detection method provided by the third embodiment of the present invention. The oil level detection method includes:

[0046] Step S101 , measuring the distance between the distance sensor 202 and the bottom of the oil cup 100 when the oil cup 100 is in an empty state.

[0047] When the range hood 10 is used for the first time and the oil cup 100 is empty (no oil in the oil cup), the distance sensor 202 measures the distance between the probe of the distance sensor 202 and the bottom of the oil cup 100 as the initial distance, and Store this initial distance into the memory 203 .

[0048] Step S102, measuring the distance between the distance sensor 202 and the oil surface in the oil cup 100 at a preset time. When the range hood 10 is in use, the distance sensor 202 will send the detected distance between the probe of the distance sensor 202 and the oil surface in the oil cup 100 to the controller 201 each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com