Car flexible side-frame material box

A flexible, material frame technology, applied in trolleys, motor vehicles, multi-axle trolleys, etc., can solve the problems of waste of space and large area of the side wall assembly material frame, and achieve the effect of simple maintenance, cost saving and quantity reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

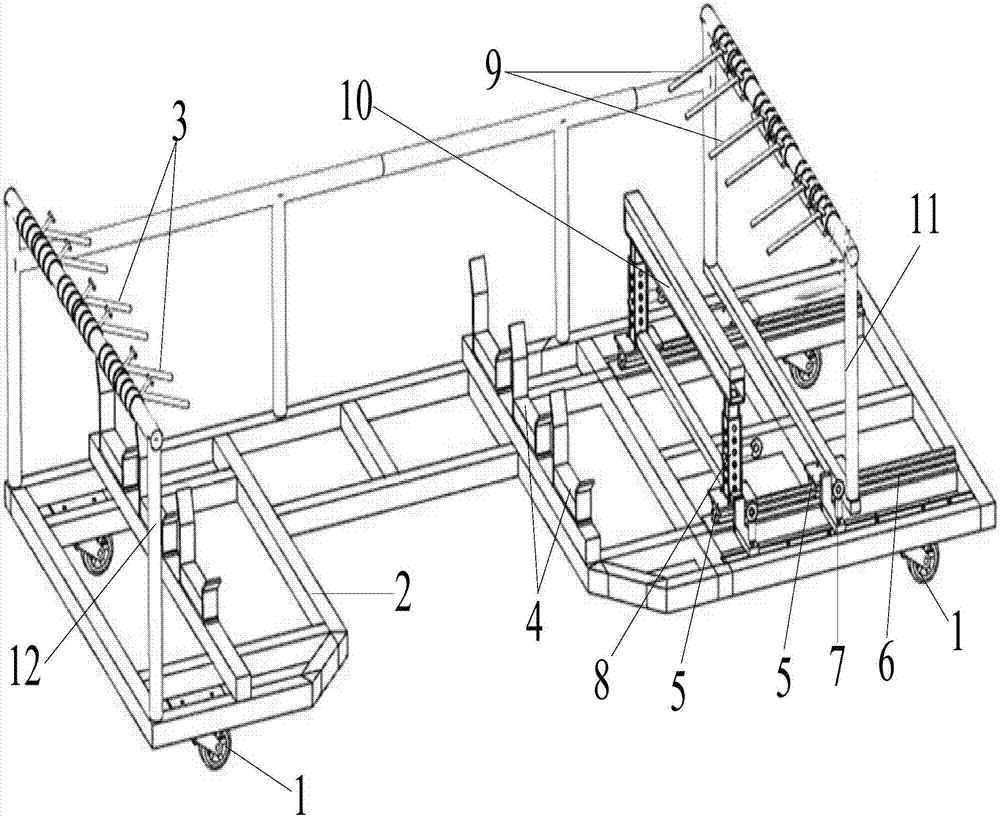

[0012] Such as figure 1 As shown, the present invention discloses a flexible side wall material frame for automobiles, including wheels 1, base 2, side wall assembly limiting parts 3, nylon rubber blocks 4, sliders 5, linear slide rails 6, and position adjustment in the front and rear directions. 7, the height direction adjuster 8, the left and right direction limit adjuster 9, the flexible side wall material frame of the automobile can be switched and adjusted according to different models to realize the placement of side wall assemblies of different sizes.

[0013] The limit bracket is installed on the slide block 5, the limit bracket includes a first limit bracket 10 and a second limit bracket 11, the linear slide rail 6 is installed on the base 2, and the slide block 5 is installed on the On the linear slide rail 6, and the slider 5 can move on the linear slide rail 6, the front and rear direction position regulator 7 is installed on the slider 5, and the first limit brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com