Locking work and detecting torsion adjusting intelligent high-integration-level industrial robot

An industrial robot, high-integration technology, applied in power tools, manufacturing tools, portable mobile devices, etc., can solve problems such as narrow placement space, tight bolts, and inability to locate large equipment bolts, and achieve the effect of protecting its own safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

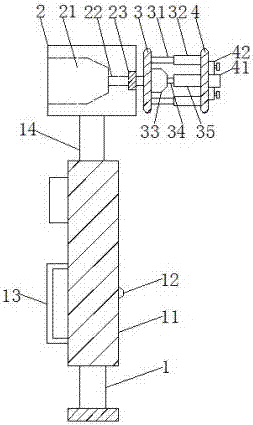

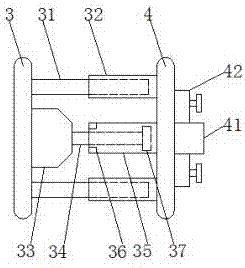

[0015] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0016] see Figure 1-4 , the present invention provides a technical solution: an intelligent high-integration industrial robot with torque adjustment for locking operation and detection, including a handle 1, the upper end of the handle 1 is fixedly connected with a telescopic sleeve 11, and the inner lower end of the telescopic sleeve 11 is fixedly connected with a The second spring 19, the upper end of the second spring 19 is fixedly connected with a gasket 18 made of rubber material, which can play the role of buffer protection. There is a circular groove 16, the inner side of the circular groove 16 is fixedly connected with the first spring 17, the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com