Motor pin pressing-in equipment

A technology of motor pins and equipment, applied in metal processing equipment, assembly machines, metal processing, etc., can solve the problems of low automation, difficulty in ensuring large-scale production, and low efficiency, and achieve high automation, simple structure, and few processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

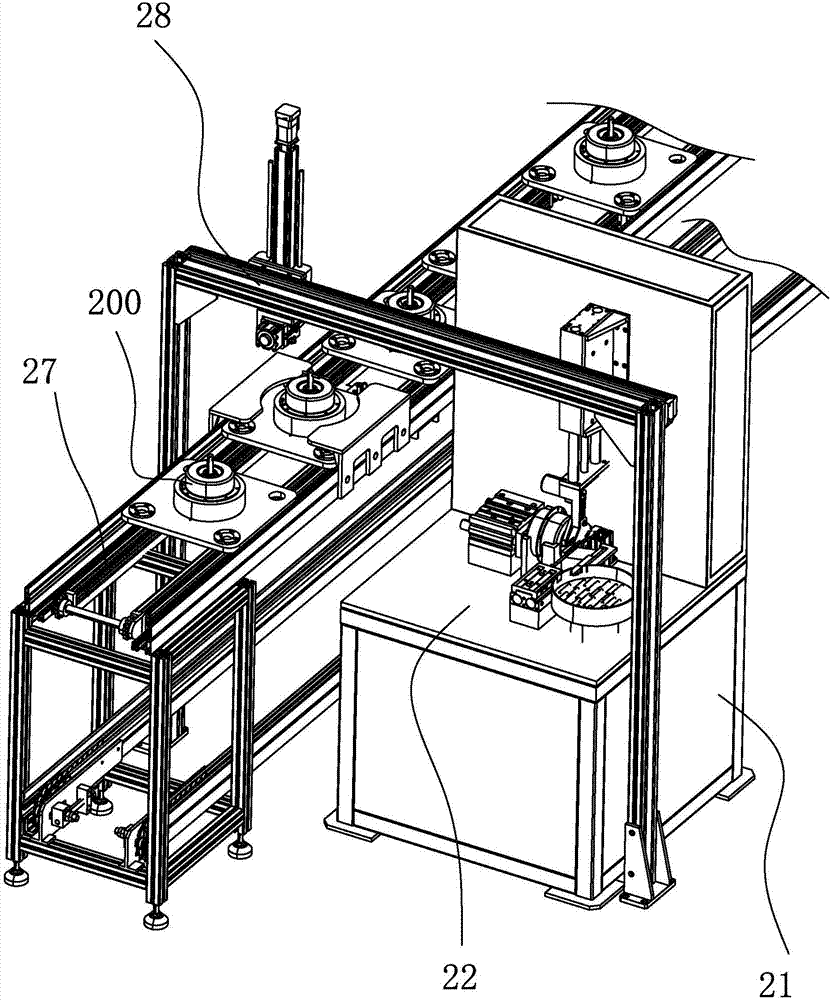

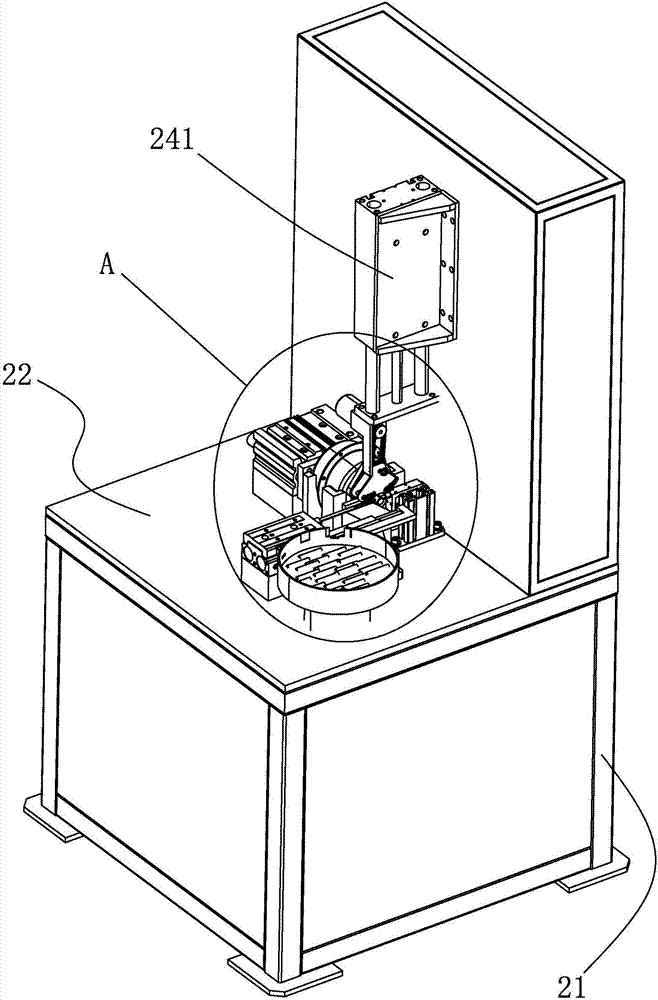

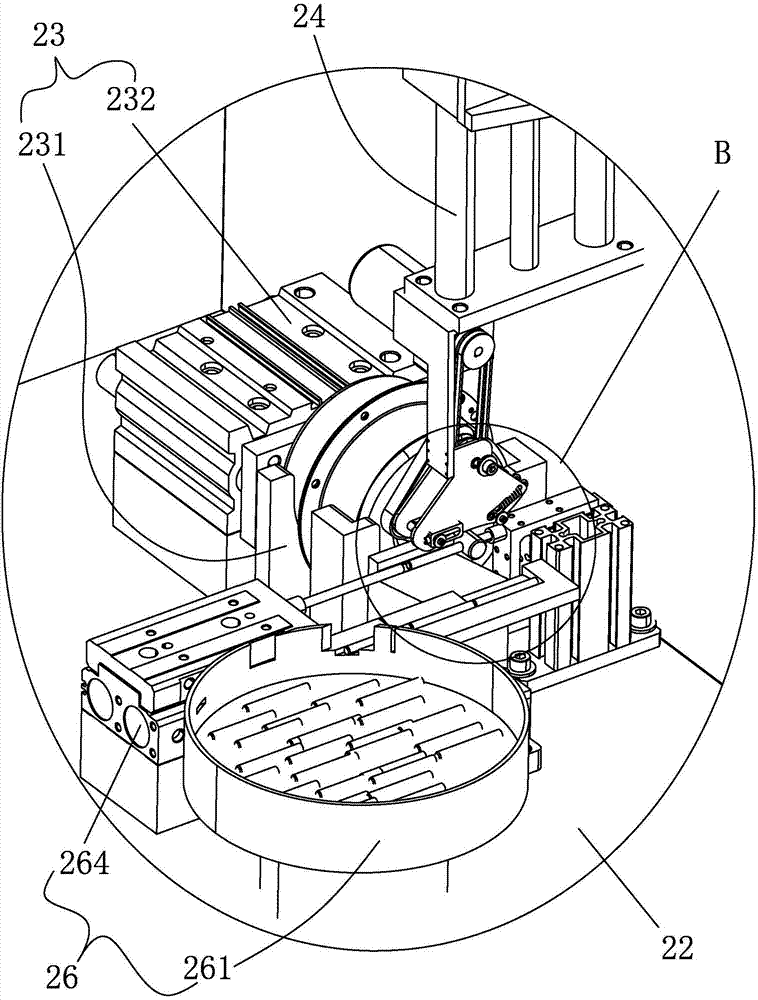

[0029] Such as Figure 1 to Figure 9 As shown, a motor pin press-in device in this embodiment includes a frame 21, and the frame 21 is provided with a horizontal table 22, and the horizontal table 22 is provided with a motor for positioning and clamping. 200 motor positioning mechanism 23, the frame 21 is provided with a motor shaft driving device 24 that drives the motor shaft 201 to rotate, and the horizontal workbench 22 is provided with a motor shaft that can be inserted into the through hole 202 on the motor shaft 201 The positioning mechanism 25, the horizontal workbench 22 is also provided with a pin automatic pressing device 26 for pressing the pin 203 into the through hole 202 on the motor shaft 201 . In the present invention, the motor 200 is first positioned and clamped on the motor positioning mechanism 23, and then the motor shaft driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com