Convenient welding device

A welding device and electric welding machine technology, applied in welding equipment, auxiliary devices, welding accessories, etc., can solve the problems of damaged insulation, easily induced electric shock accidents, inconvenient power supply line retraction, etc., to prevent electric shock and meet power supply plug-in Requirements, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

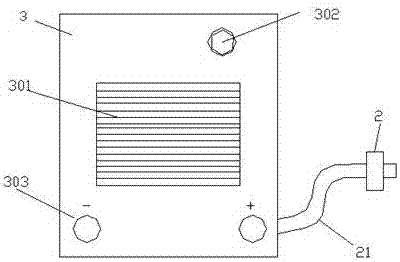

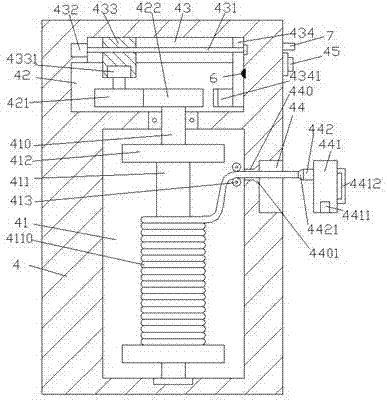

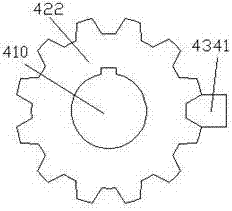

[0022] Such as Figure 1-Figure 6 As shown, a convenient welding device of the present invention includes an electric welding machine 3 and a power distribution part 4, and the inside of the power distribution part 4 is provided with a first cavity 41, and the distribution part on the top of the first cavity 41 is The electrical part 4 is provided with a second cavity 42, the top wall of the second cavity 42 is provided with a sliding groove 43, and the outer wall of the power distribution part 4 on the right side of the first cavity 41 is provided with a placement Groove 44, a perforation 440 is provided between the settling groove 44 and the first cavity 41, a revolving pin shaft 410 extending up and down is provided in the first cavity 41, and the top of the revolving pin shaft 410 passes through Pass through the inner wall of the power distribution part 4 and enter the second cavity 42 and be connected by rotation. The upper and lower sides of the rotating tube 411 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com