All-in-one machine capable of feeding, drying and compositing fiberglass cloth

A glass fiber cloth and integrated machine technology, applied in the field of machinery, can solve the problems of low production efficiency and inconvenient adjustment, and achieve the effect of reducing hot air emissions, wide application range and good environmental protection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

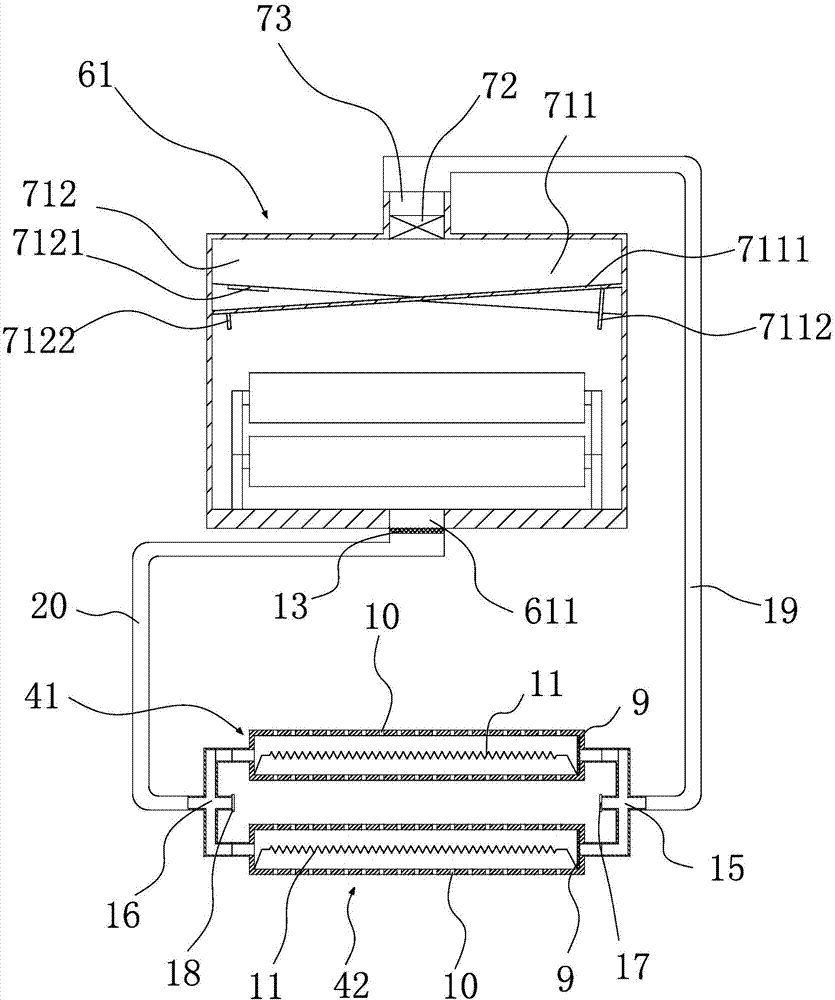

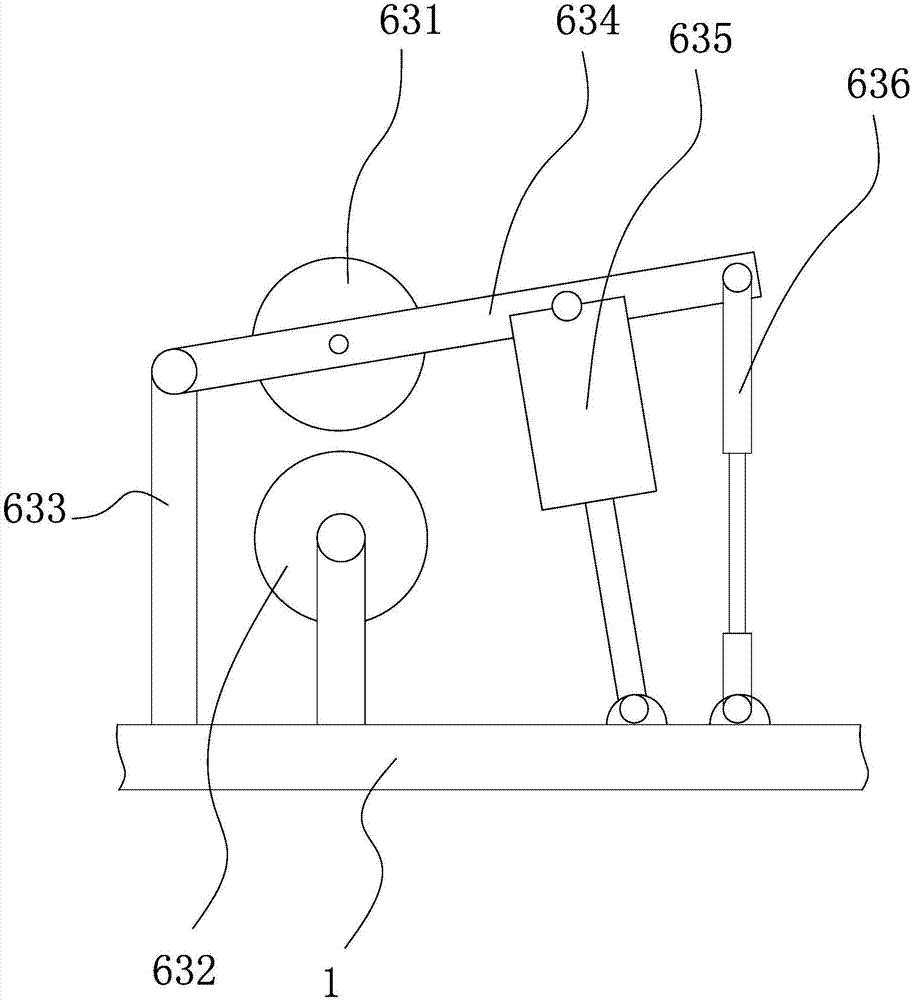

[0024] refer to figure 1 , this embodiment is a glass fiber cloth feeding and drying compound machine, comprising a frame 1 arranged horizontally and horizontally, the bottom surface of the frame 1 is provided with a controller 2, and the top surface of the frame 1 is along the direction of the glass fiber cloth. In the conveying direction, a feeding device 3 , a preheating device 4 , a gluing device 5 , a composite drying device 6 , a cooling device 7 and a winding frame 8 are arranged in sequence. The feeding device 3 includes a first feeding roller 31 and a second feeding roller 32 that are independent of each other. The glue applying device 5 includes a glue box 51 and a glue box 12 positioned at the top of the glue bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com