Anti-collision wind suction type water dripping frame

A drip rack, anti-collision technology, applied in the direction of test tube brackets/clamps, etc., can solve problems such as easy damage, test tube shaking, and impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below, the technical solution of the present invention will be described in detail through specific examples.

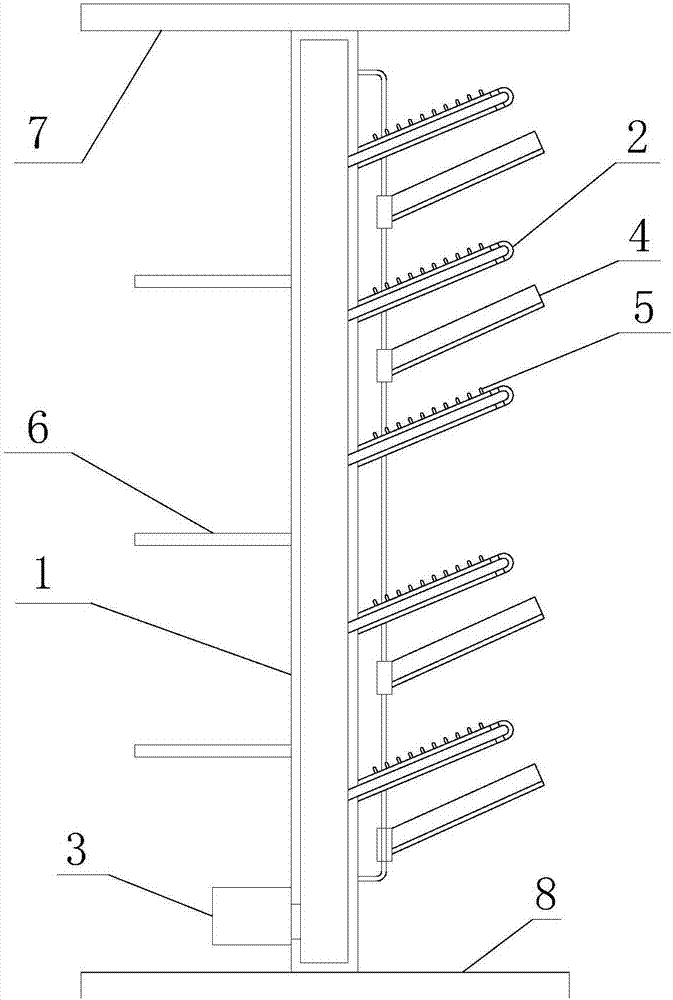

[0018] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of an anti-collision air suction drip rack proposed by the present invention.

[0019] refer to figure 1 , a kind of anti-collision air suction drip stand proposed by the embodiment of the present invention, comprising: a board body 1 and a rod body 2 fixed to the board body 1 at one end, wherein:

[0020] There is a clamping cavity inside the plate body 1, the clamping cavity has an air port, and a negative pressure generator 3 is provided at the gas port, and the negative pressure generator 3 is used to generate negative pressure at the gas port; the height of the end of the rod body 2 away from the plate body 1 from the horizontal Larger than the end close to the plate body 1, the inside of the rod body 2 is provided with a linear cavity connected with the clamp cavity, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com