Stirring cup body and cell wall breaking machine

A mixing cup and wall breaking machine technology, which is applied in home appliances, applications, kitchen utensils, etc., can solve the problems of large noise in the mixing cup, insufficient whipping, and lumps, so as to achieve high crushing efficiency and improve whipping Performance, the effect of improving whipping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

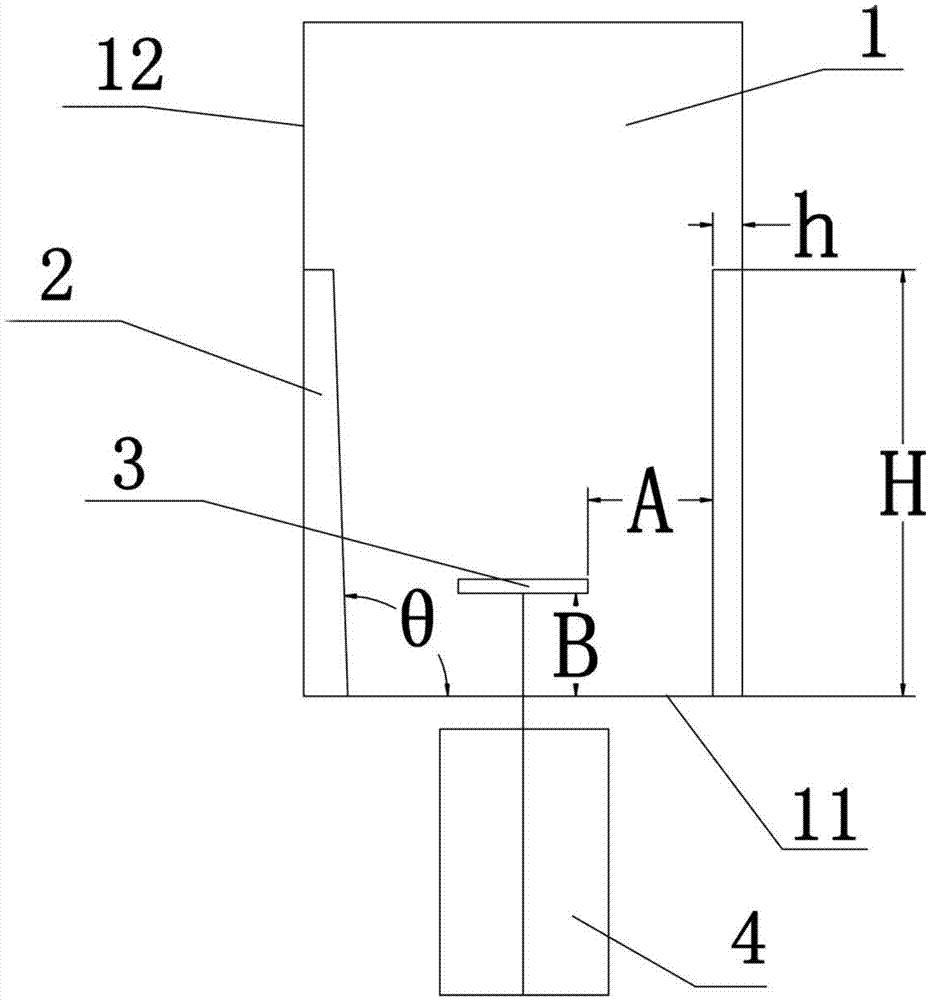

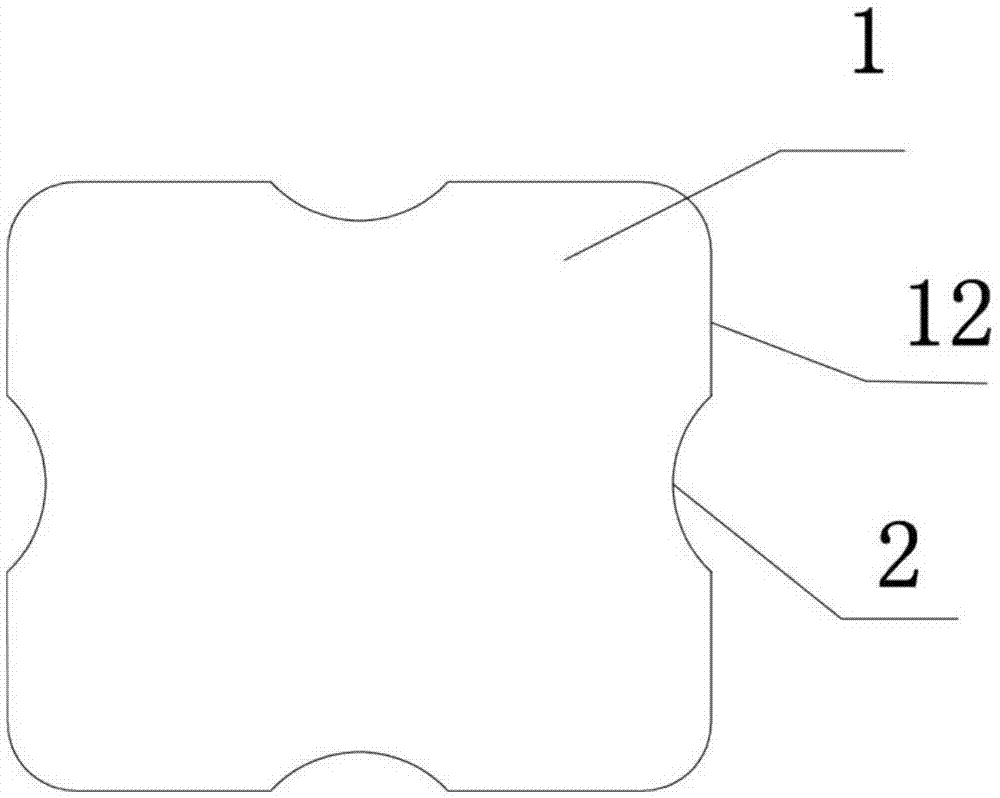

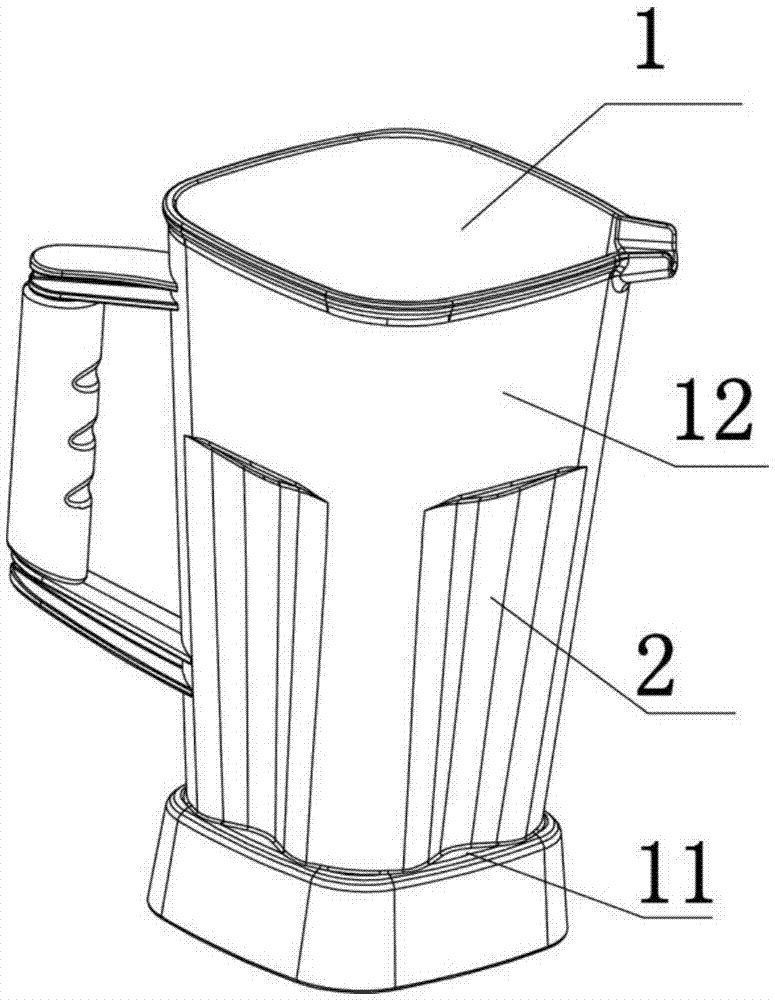

[0047] Such as Figure 1 ~ Figure 3 As shown, a stirring cup of this embodiment is detachably installed on the main machine of the wall breaker, and a stirring knife 3 is installed on the inner side of the bottom wall 11; the inner side of the side wall 12 of the stirring cup 1 A plurality of spoiler ribs 2 are integrally connected. The spoiler ribs 2 are linear convex ribs formed by indenting the side wall 12 of the stirring cup body 1 in the direction of the central axis of the stirring cup body 1. The cross-sections of each height of the linear convex ribs are The shapes are the same, the heights of the depressions are equal, but the width of the cross-section gradually decreases from the top; the plurality of spoiler ribs 2 are all in a linear structure and arranged longitudinally on the inner side of the side wall 12 of the mixing cup body 1. One end of the rib 2 is located on the inner surface of the bottom wall 11 of the stirring cup body 1, and the other end is located...

Embodiment approach 1

[0048] Embodiment 1: The cross-section of the side of the spoiler 2 located in the stirring cup body 1 is arc-shaped, that is, the side of the spoiler 2 located in the stirring cup 1 is an arc-shaped structure. The curved structure and the curved surface structure have uniform whipping strength. During the working process of the mixing cup body, when the ingredients collide with the spoiler ribs in the stirring cup body, it can reduce rigid collision, reduce noise, and is easy to clean.

Embodiment approach 2

[0049]Embodiment 2: The cross-section of the spoiler rib 2 is polygonal, and the lengths of the sides of the polygon located in the stirring cup body 1 are equal, and every two adjacent sides pass through an arc transition; that is, the spoiler rib 2 is located in the stirring cup One side of the body 1 is a multi-ribbon structure. This structure has high whipping strength, and each side can effectively apply force, which can increase the collision area between the ingredients and the spoiler ribs during the whipping process, and avoid the same area of the spoiler ribs. Repeated rigid collision reduces noise. The cross-section of the spoiler rib 2 in this embodiment is preferably triangular, and the lengths of the two sides of the triangle inside the stirring cup 1 are equal, and the included angle is not less than 90°.

[0050] Such as figure 2 with image 3 As shown, a plurality of spoiler ribs 2 in this embodiment are uniformly arranged around the central axis of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com