Gift-box milk case automatic case sealing mechanism

A milk carton and gift box technology, applied in packaging and other directions, can solve the problems of low efficiency and high cost of manual carton sealing, and achieve the effects of reducing labor costs, realizing double settling, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

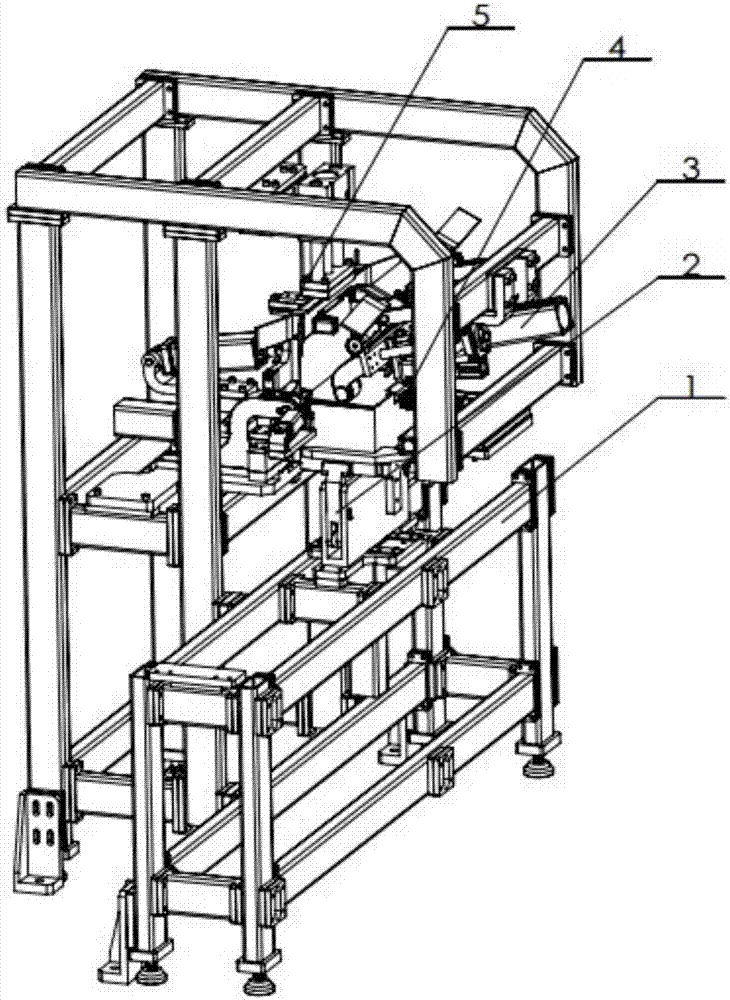

[0021] Such as figure 1 As shown, an automatic sealing mechanism for a gift box milk carton includes a complete machine frame 1, a positioning unit 2, a pressing plate unit 3, a bending unit 4, and a cover bending unit 5, the positioning unit 2, the pressing plate unit 3, and the bending unit. The unit 4 and the cover bending unit 5 are installed on the machine frame 1. The positioning unit 2 can realize the accurate double positioning of the gift box milk box; the pressing plate unit 3 can realize the crimping of the inner cardboard, and the bending unit 4 can realize the outward lifting The cover is bent to prepare for the subsequent installation into the reserved groove. The cover bending unit 5 can complete the bending of the inner flip cover, the outer cardboard and the inner flip cover, and the subsequent bending unit snaps into the completed bending The outer flap of the milk box completes all the steps of the automatic sealing of the milk box.

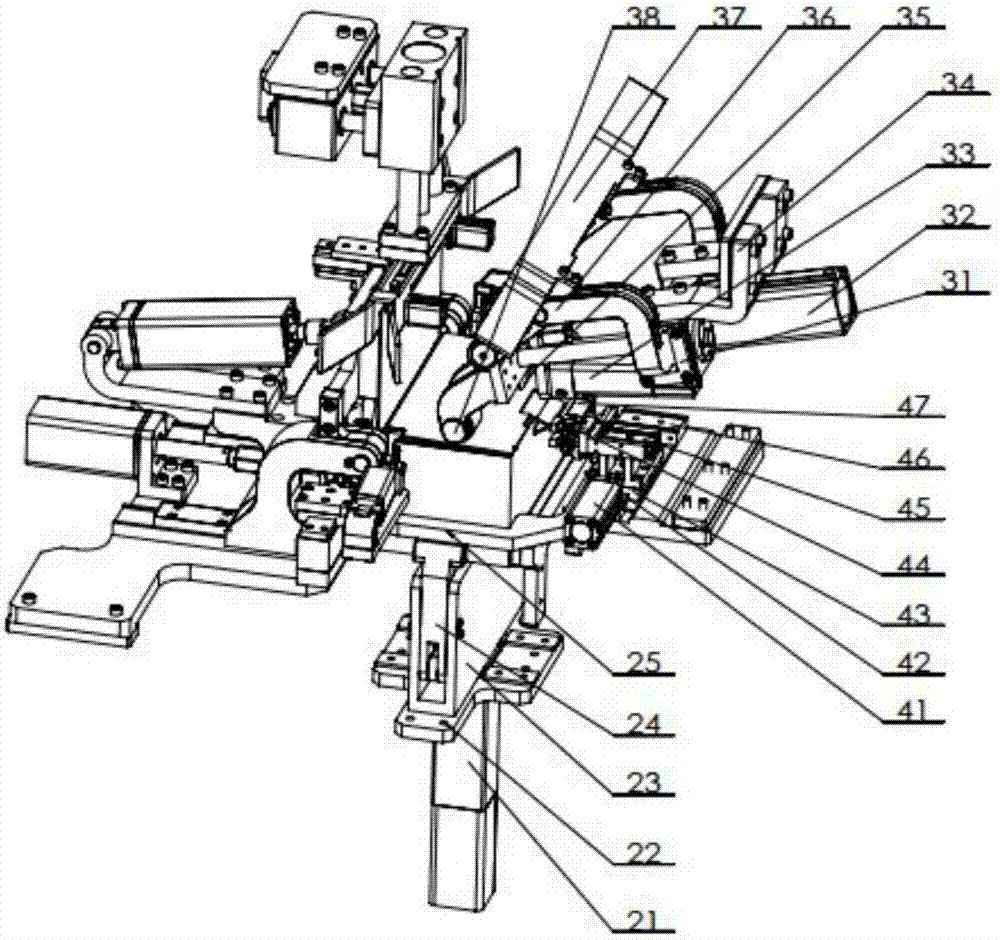

[0022] Such as figure 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com