Cylindrical article peripheral face hot stamping machine

A technology for hot stamping machines and articles, which is applied to printing machines, rotary printing machines, printing, etc., and can solve problems such as hot stamping on the peripheral surface of difficult-to-cylindrical articles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

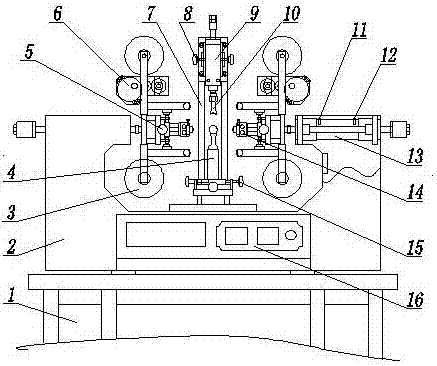

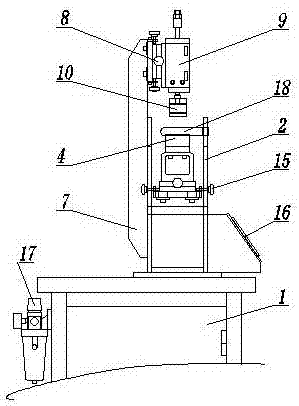

[0011] As shown in the figure, a horizontal plate body 2 is installed on the bottom box 1, and a control panel 16 is installed in front of the horizontal plate body 2. There is a bottom mold fine-tuning 15, a bottom mold 4 is mounted on the bottom mold fine-tuning 15, a vertical clamping cylinder 9 is installed on the upper part of the vertical board body 7, and a clamping cylinder fine-tuning 8 is arranged between the clamping cylinder 9 and the vertical board body 7 , the lower end of the clamping cylinder 9 cylinder rods is equipped with a clamping upper die 10;

[0012] Two relative horizontal hot stamping cylinders 13 are housed on the horizontal plate body 2 on the left and right sides of the vertical board body 7, and the built-in cylinder rod of the hot stamping cylinder 13 is equipped with a heating head fine-tuning 5 and a heating hot stamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com