Automatic sub-packaging equipment with double sub-packaging heads used for dam glue production

A technology of dispensing and damming, which is applied in the field of automatic dispensing equipment with double dispensing heads, can solve problems such as difficult control of dispensing measurement, large dispensing volume, and poor quality of damming glue, etc., to improve operation The effect of high reliability and packing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

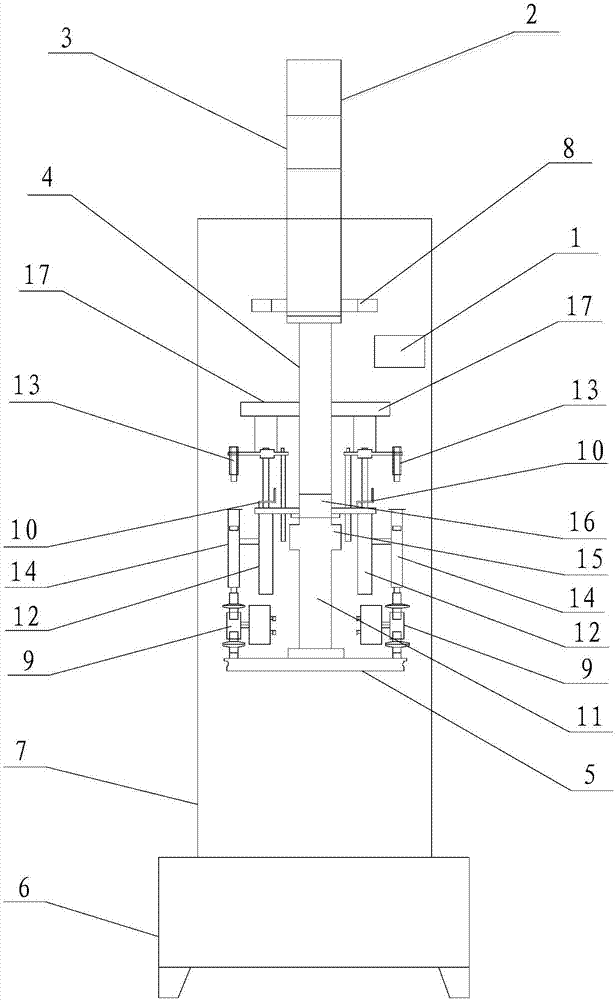

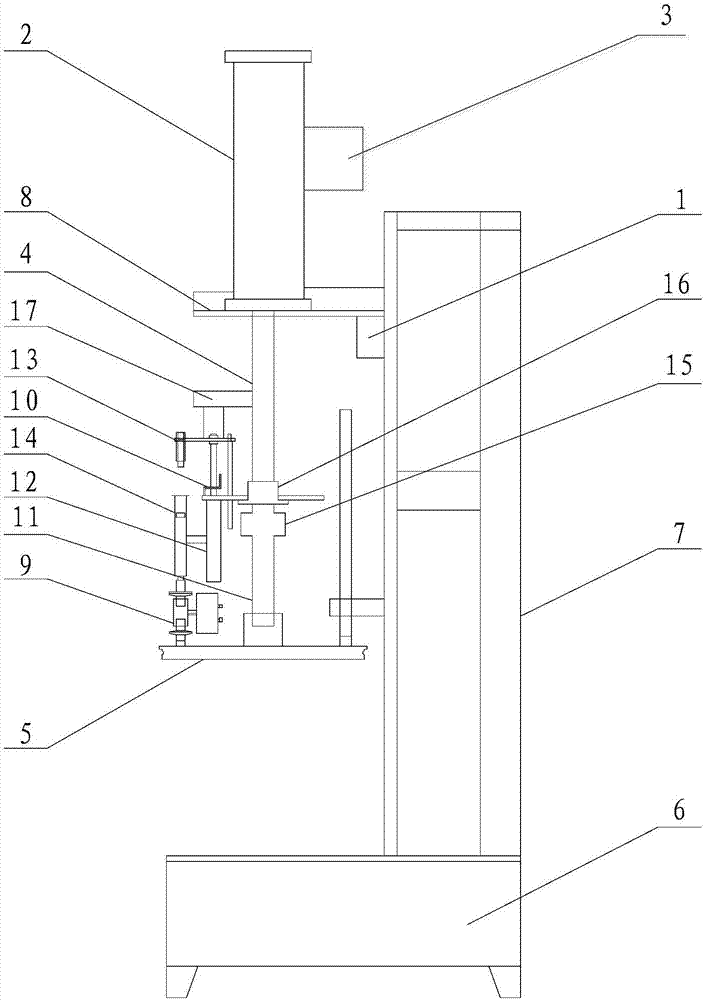

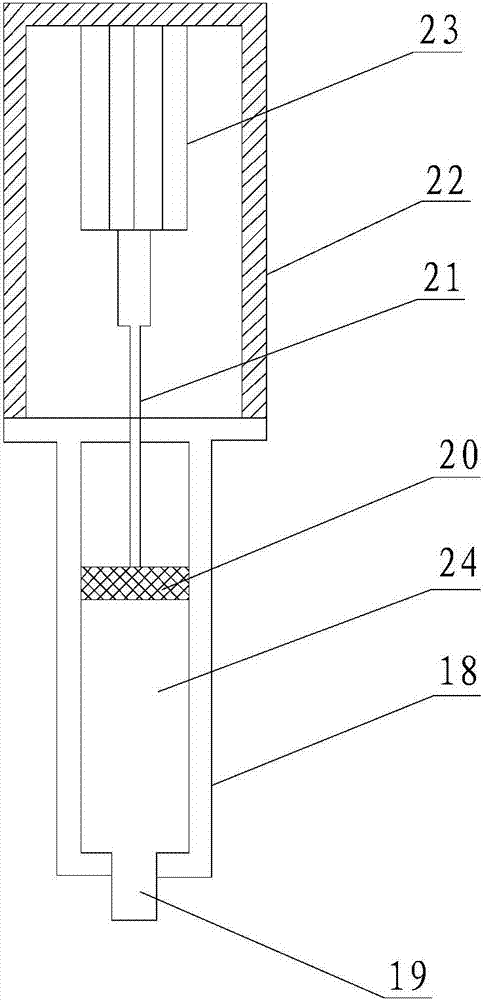

[0028] Such as Figures 1 to 2 As shown, an automatic subpackaging equipment with double subpackaging heads for the production of dam rubber, including a frame, a material barrel 2, a peristaltic pump 3, a main material tube 4, two subpackaging components, a servo motor 15, a pair of Driving device 17 and curing molding part 5, described frame is made up of the first frame plate 6 that is arranged horizontally and the second frame plate 7 that is perpendicular to described first frame plate 6 one end; Said second frame A fixed plate 8 is vertically arranged on the side of the plate 7 facing the other end of the first frame plate 6; the barrel 2 is vertically arranged on the fixed plate 8; the peristaltic pump 3 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com