Preparation method of polymer separation membrane with antibacterial and anti-biological pollution properties

An anti-biological pollution, polymer technology, applied in the direction of semi-permeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problems of easy desorption of antibacterial agent modified layer, unfavorable commercial production, loss of anti-pollution ability, etc. , to achieve improved antibacterial and anti-pollution performance, long-lasting anti-pollution effect, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

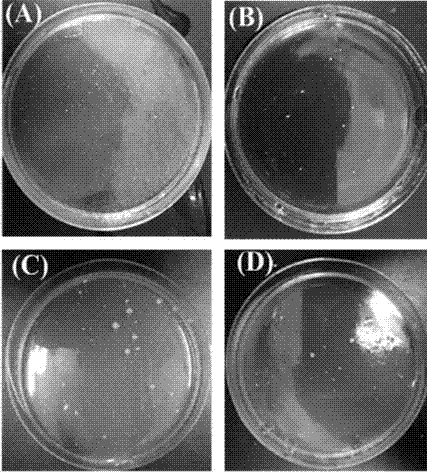

Embodiment 1

[0028] The PVDF separation membrane was soaked in clean water for 24 h to remove the impurities on the surface of the PVDF separation membrane (denoted as M0). Place the pretreated isolate membrane in a polytetrafluoroethylene closed box (single-sided reaction box), add 1 g / L dopamine, use Tris-HCl (10 mM) to adjust the pH=8.0, and place it on a shaker Medium, 250 rpm, 20 o The reaction was carried out at C for 5 h until a gray PDA layer appeared on the membrane. After that, alternately with water and ethanol at 40 o C. Wash at 200 rpm for 24 h. use N 2 Blow dry to obtain a dopamine-coated PVDF separation membrane (denoted as M1). Dissolve 3.0 mL of TMOS in 100 mL of HCl aqueous solution, stir for 30 min, mix with 100 mL of PBS, then place the dopamine-coated PVDF separation membrane in it immediately, react at 25°C for 7 h, wash with water Overnight, get the polyphenolic compound-nanometer silica carrier PVDF membrane (denoted as M2); configure 5mL / 50mL QAC aqueous solut...

Embodiment 2

[0030] Soak the PVDF separation membrane in clean water for 24 h to remove impurities on the surface of the PVDF separation membrane. Place the pretreated isolate membrane in a polytetrafluoroethylene closed box (single-sided reaction box), add 1 g / L dopamine, use Tris-HCl (10 mM) to adjust the pH=8.0, and place it on a shaker Medium, 250 rpm, 20 o The reaction was carried out at C for 5 h until a gray PDA layer appeared on the membrane. After that, alternately with water and ethanol at 40 o C. Wash at 200 rpm for 24 h. use N 2 Blow dry to obtain a dopamine-coated PVDF separation membrane. Dissolve 3.0 mL of TMOS in 100 mL of HCl aqueous solution, stir for 30 min, mix with 100 mL of PBS, then place the obtained dopamine-coated PVDF separation membrane in it immediately, react at 25°C for 7 h, wash with water overnight , to obtain the polyphenolic compound-nanometer silica carrier PVDF membrane; configure 5mL / 50mL QAC aqueous solution (adjust pH=4), place the membrane M2 i...

Embodiment 3

[0032] Soak the PES separation membrane in clean water for 24 h to remove impurities on the surface of the PES separation membrane. Place the pretreated isolate membrane in a polytetrafluoroethylene closed box (single-sided reaction box), add 1 g / L dopamine, use Tris-HCl (10 mM) to adjust the pH=8.0, and place it on a shaker Medium, 250 rpm, 20 o The reaction was carried out at C for 5 h until a gray PDA layer appeared on the membrane. After that, alternately with water and ethanol at 40 oC. Wash at 200 rpm for 24 h. use N 2 Blow dry to obtain a dopamine-coated PES separation membrane. Dissolve 2.0 mL TMOS in 100 mL HCl aqueous solution, stir for 30 min, mix with 100 mL PBS, then place the dopamine-coated PES separation membrane in it immediately, react at 25°C for 7 h, wash with water Overnight, obtain the polyphenolic compound-nano silica carrier PES membrane; configure 5mL / 50mL QAC aqueous solution (adjust pH=4), place the membrane M2 in it, at 25 o C conditions were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com