Combined type PFC inductor

A combined, inductive technology, applied in the field of inductance, can solve the problems of low production efficiency, high labor cost, affecting product quality, etc., to achieve the effect of improving production efficiency, reducing labor, and solving the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

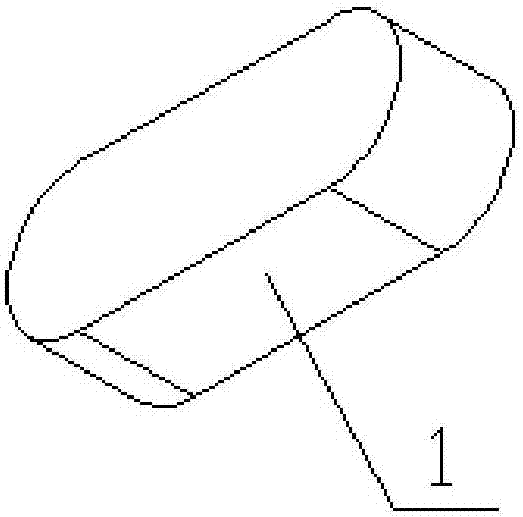

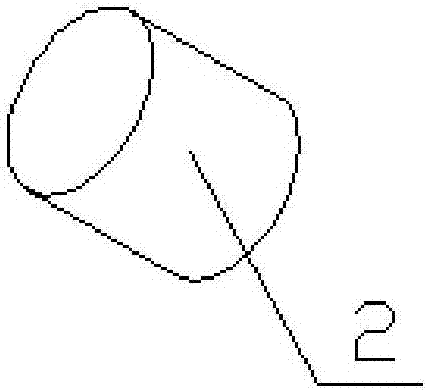

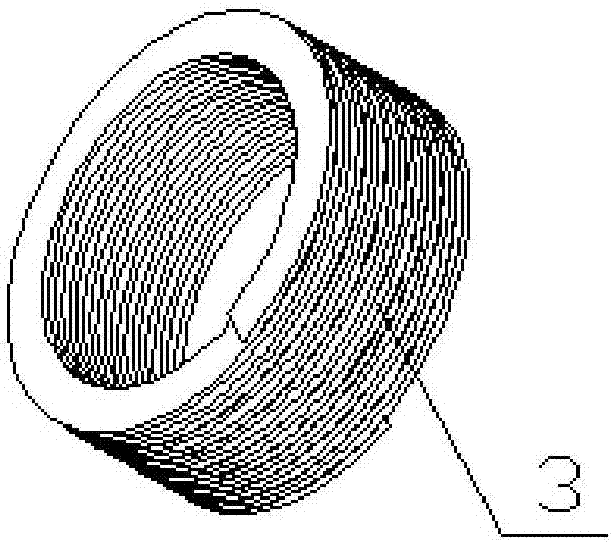

[0013] Such as Figure 1 to Figure 3 As shown, a combined PFC inductor includes two first magnetic cores 1, two second magnetic cores 2 and two coil windings 3, the two first magnetic cores are arranged in parallel up and down, and the two second magnetic cores The two magnetic cores are arranged side by side between two first magnetic cores and are located on both sides of the length of the first magnetic core. on the second core. The two second magnetic cores are first glued and fixed with one of the first magnetic cores, then the coil windings are placed on the second magnetic cores, and finally the other first magnetic core is glued and installed. The coil windings can be The winding is good, which solves the difficulty of making the winding, the most important process in the manufacturing process of the inductor. In addition, the coil winding is made of flat wire, and the flat wire can be wound on the improved spring machine first, with high winding efficiency and good ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com