High-temperature irradiation creeping device

A creep device and high-temperature irradiation technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as inability to measure deformation, affect nuclear energy safety, and reduce mechanical properties of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

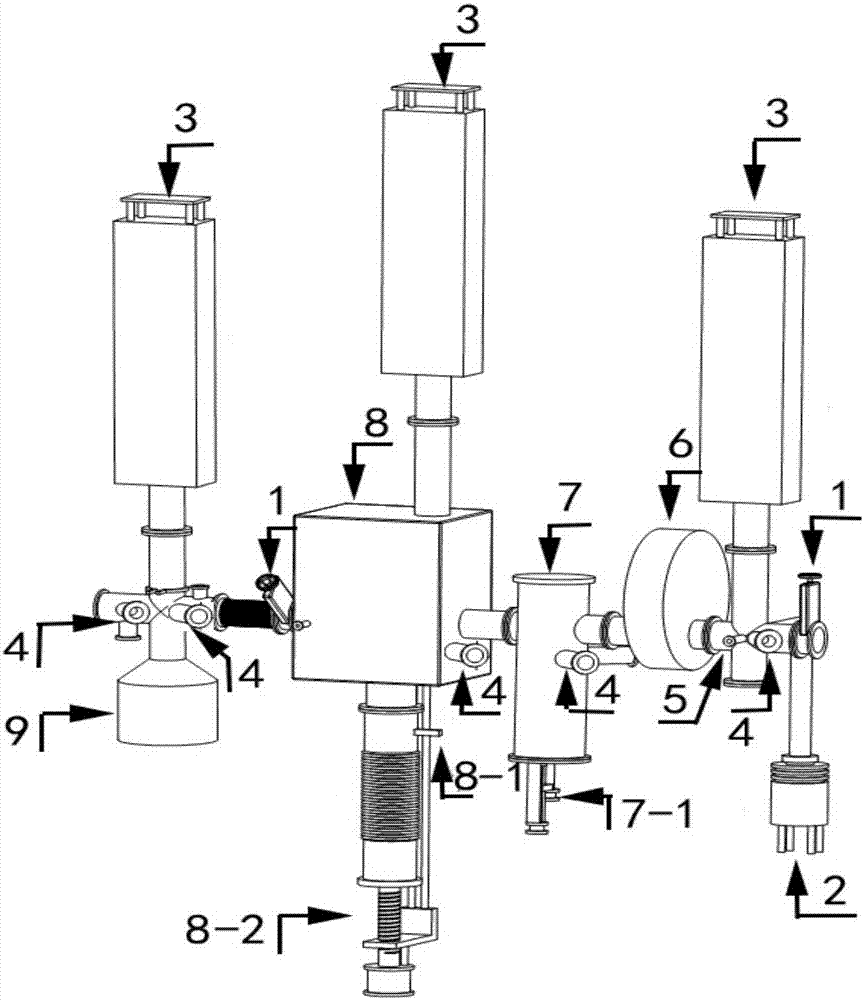

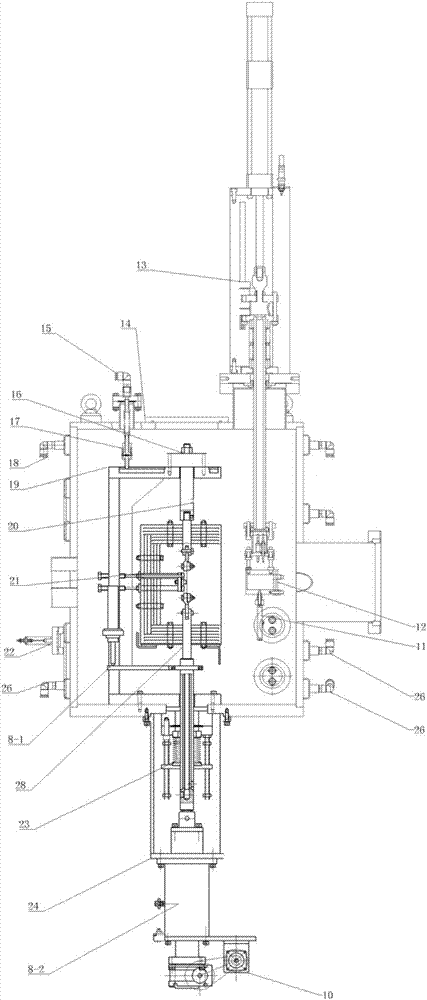

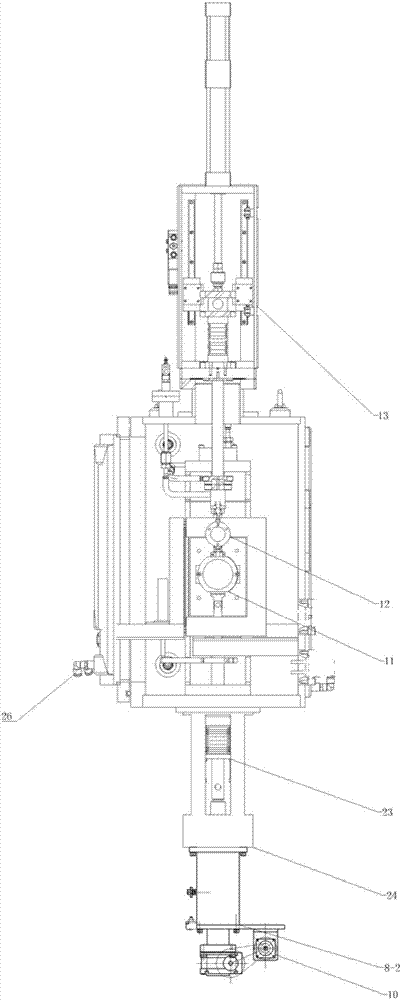

[0022] Below in conjunction with the best examples shown in the accompanying drawings for further details:

[0023] Such as Figures 1 to 5 As shown, the high-temperature irradiation creep device is characterized in that it includes a high-temperature target chamber 8, and the lower end of the high-temperature target chamber 8 is provided with a differential transformer 8-1 and a stress loading system 8-2, and the high-temperature target chamber 8 An observation window 4 and a beam current detection system 3 are also arranged on it, and one side of the high-temperature target chamber 8 is connected to a leakage tank 9 through a vacuum gate valve 1 and a vacuum pipeline. The other side of the target chamber 8 is connected to the normal temperature target chamber 7 through a vacuum pipeline. The normal temperature target chamber 7 is provided with an observation window 4 and a rotating lifting system 3. The normal temperature target chamber 7 is connected to the energy reduction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com